443

442

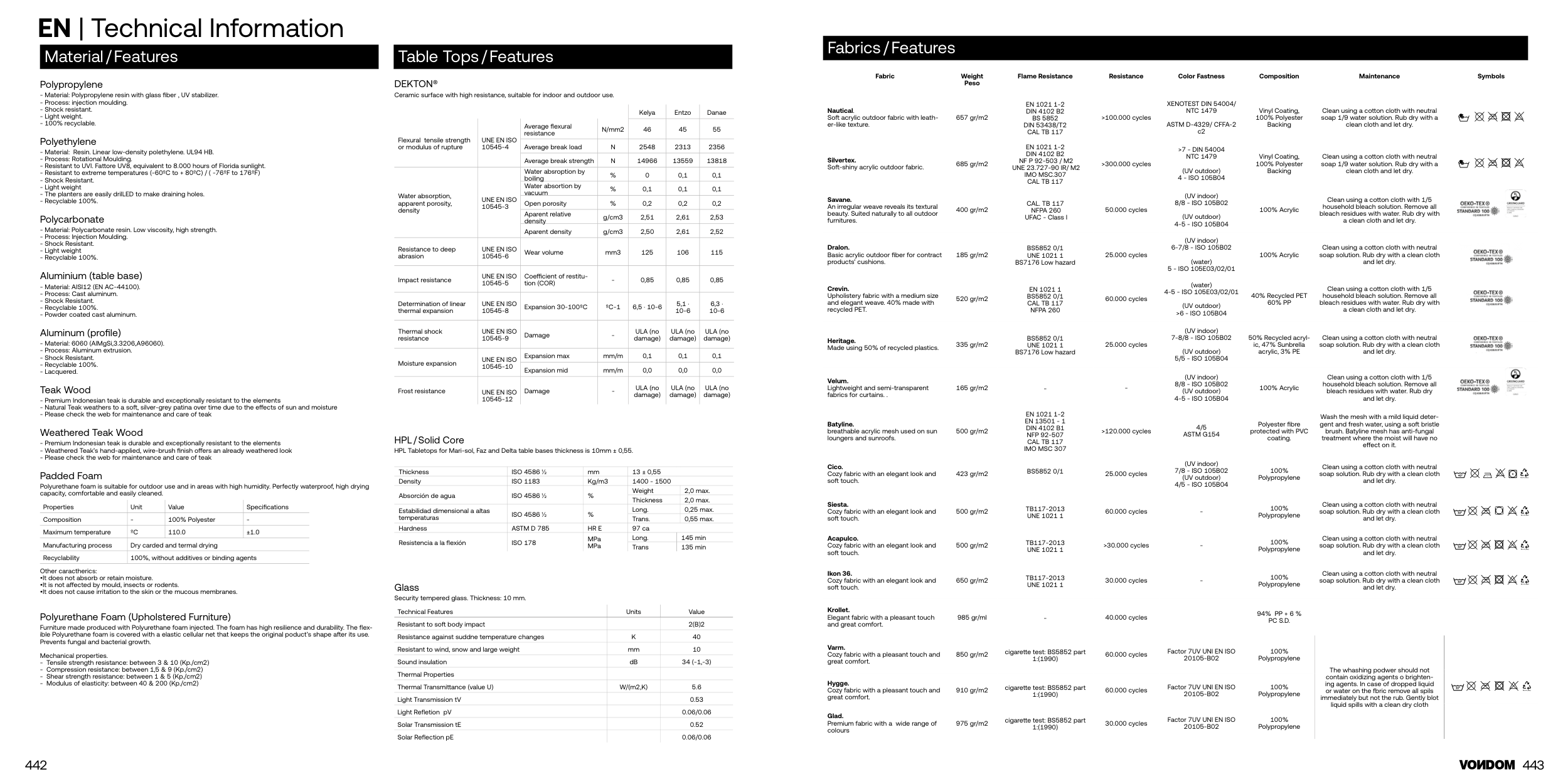

Fabrics / Features

Fabric

Weight

Peso

Flame Resistance

Resistance

Color Fastness

Composition

Maintenance

Symbols

Nautical.

Soft acrylic outdoor fabric with leath-

er-like texture.

657 gr/m2

EN 1021 1-2

DIN 4102 B2

BS 5852

DIN 53438/T2

CAL TB 117

>100.000 cycles

XENOTEST DIN 54004/

NTC 1479

ASTM D-4329/ CFFA-2

c2

Vinyl Coating,

100% Polyester

Backing

Clean using a cotton cloth with neutral

soap 1/9 water solution. Rub dry with a

clean cloth and let dry.

Silvertex.

Soft-shiny acrylic outdoor fabric.

685 gr/m2

EN 1021 1-2

DIN 4102 B2

NF P 92-503 / M2

UNE 23.727-90 IR/ M2

IMO MSC.307

CAL TB 117

>300.000 cycles

>7 - DIN 54004

NTC 1479

(UV outdoor)

4 - ISO 105B04

Vinyl Coating,

100% Polyester

Backing

Clean using a cotton cloth with neutral

soap 1/9 water solution. Rub dry with a

clean cloth and let dry.

Savane.

An irregular weave reveals its textural

beauty. Suited naturally to all outdoor

furnitures.

400 gr/m2

CAL. TB 117

NFPA 260

UFAC - Class I

50.000 cycles

(UV indoor)

8/8 - ISO 105B02

(UV outdoor)

4-5 - ISO 105B04

100% Acrylic

Clean using a cotton cloth with 1/5

household bleach solution. Remove all

bleach residues with water. Rub dry with

a clean cloth and let dry.

Dralon.

Basic acrylic outdoor fiber for contract

products’ cushions.

185 gr/m2

BS5852 0/1

UNE 1021 1

BS7176 Low hazard

25.000 cycles

(UV indoor)

6-7/8 - ISO 105B02

(water)

5 - ISO 105E03/02/01

100% Acrylic

Clean using a cotton cloth with neutral

soap solution. Rub dry with a clean cloth

and let dry.

Crevin.

Upholistery fabric with a medium size

and elegant weave. 40% made with

recycled PET.

520 gr/m2

EN 1021 1

BS5852 0/1

CAL TB 117

NFPA 260

60.000 cycles

(water)

4-5 - ISO 105E03/02/01

(UV outdoor)

>6 - ISO 105B04

40% Recycled PET

60% PP

Clean using a cotton cloth with 1/5

household bleach solution. Remove all

bleach residues with water. Rub dry with

a clean cloth and let dry.

Heritage.

Made using 50% of recycled plastics.

335 gr/m2

BS5852 0/1

UNE 1021 1

BS7176 Low hazard

25.000 cycles

(UV indoor)

7-8/8 - ISO 105B02

(UV outdoor)

5/5 - ISO 105B04

50% Recycled acryl-

ic, 47% Sunbrella

acrylic, 3% PE

Clean using a cotton cloth with neutral

soap solution. Rub dry with a clean cloth

and let dry.

Velum.

Lightweight and semi-transparent

fabrics for curtains. .

165 gr/m2

-

-

(UV indoor)

8/8 - ISO 105B02

(UV outdoor)

4-5 - ISO 105B04

100% Acrylic

Clean using a cotton cloth with 1/5

household bleach solution. Remove all

bleach residues with water. Rub dry

and let dry.

Batyline.

breathable acrylic mesh used on sun

loungers and sunroofs.

500 gr/m2

EN 1021 1-2

EN 13501 - 1

DIN 4102 B1

NFP 92-507

CAL TB 117

IMO MSC 307

>120.000 cycles

4/5

ASTM G154

Polyester fibre

protected with PVC

coating.

Wash the mesh with a mild liquid deter-

gent and fresh water, using a soft bristle

brush. Batyline mesh has anti-fungal

treatment where the moist will have no

effect on it.

Cico.

Cozy fabric with an elegant look and

soft touch.

423 gr/m2

BS5852 0/1

25.000 cycles

(UV indoor)

7/8 - ISO 105B02

(UV outdoor)

4/5 - ISO 105B04

100%

Polypropylene

Clean using a cotton cloth with neutral

soap solution. Rub dry with a clean cloth

and let dry.

Siesta.

Cozy fabric with an elegant look and

soft touch.

500 gr/m2

TB117-2013

UNE 1021 1

60.000 cycles

-

100%

Polypropylene

Clean using a cotton cloth with neutral

soap solution. Rub dry with a clean cloth

and let dry.

Acapulco.

Cozy fabric with an elegant look and

soft touch.

500 gr/m2

TB117-2013

UNE 1021 1

>30.000 cycles

-

100%

Polypropylene

Clean using a cotton cloth with neutral

soap solution. Rub dry with a clean cloth

and let dry.

Ikon 36.

Cozy fabric with an elegant look and

soft touch.

650 gr/m2

TB117-2013

UNE 1021 1

30.000 cycles

-

100%

Polypropylene

Clean using a cotton cloth with neutral

soap solution. Rub dry with a clean cloth

and let dry.

Krollet.

Elegant fabric with a pleasant touch

and great comfort.

985 gr/ml

-

40.000 cycles

94% PP + 6 %

PC S.D.

Varm.

Cozy fabric with a pleasant touch and

great comfort.

850 gr/m2

cigarette test: BS5852 part

1:(1990)

60.000 cycles

Factor 7UV UNI EN ISO

20105-B02

100%

Polypropylene

The whashing podwer should not

contain oxidizing agents o brighten-

ing agents. In case of dropped liquid

or water on the fbric remove all spils

immediately but not the rub. Gently blot

liquid spills with a clean dry cloth

Hygge.

Cozy fabric with a pleasant touch and

great comfort.

910 gr/m2

cigarette test: BS5852 part

1:(1990)

60.000 cycles

Factor 7UV UNI EN ISO

20105-B02

100%

Polypropylene

Glad.

Premium fabric with a wide range of

colours

975 gr/m2

cigarette test: BS5852 part

1:(1990)

30.000 cycles

Factor 7UV UNI EN ISO

20105-B02

100%

Polypropylene

Material / Features

Polypropylene

- Material: Polypropylene resin with glass fiber , UV stabilizer.

- Process: injection moulding.

- Shock resistant.

- Light weight.

- 100% recyclable.

Polyethylene

- Material: Resin. Linear low-density polethylene. UL94 HB.

- Process: Rotational Moulding.

- Resistant to UVI. Fattore UV8, equivalent to 8.000 hours of Florida sunlight.

- Resistant to extreme temperatures (-60ºC to + 80ºC) / ( -76ºF to 176ºF)

- Shock Resistant.

- Light weight

- The planters are easily drilLED to make draining holes.

- Recyclable 100%.

Polycarbonate

- Material: Polycarbonate resin. Low viscosity, high strength.

- Process: Injection Moulding.

- Shock Resistant.

- Light weight

- Recyclable 100%.

Aluminium (table base)

- Material: AISI12 (EN AC-44100).

- Process: Cast aluminum.

- Shock Resistant.

- Recyclable 100%.

- Powder coated cast aluminum.

Aluminum (profile)

- Material: 6060 (AlMgSi,3.3206,A96060).

- Process: Aluminum extrusion.

- Shock Resistant.

- Recyclable 100%.

- Lacquered.

Teak Wood

- Premium Indonesian teak is durable and exceptionally resistant to the elements

- Natural Teak weathers to a soft, silver-grey patina over time due to the effects of sun and moisture

- Please check the web for maintenance and care of teak

Weathered Teak Wood

- Premium Indonesian teak is durable and exceptionally resistant to the elements

- Weathered Teak’s hand-applied, wire-brush finish offers an already weathered look

- Please check the web for maintenance and care of teak

Padded Foam

Polyurethane foam is suitable for outdoor use and in areas with high humidity. Perfectly waterproof, high drying

capacity, comfortable and easily cleaned.

Properties

Unit

Value

Specifications

Composition

-

100% Polyester

-

Maximum temperature

ºC

110.0

±1.0

Manufacturing process

Dry carded and termal drying

Recyclability

100%, without additives or binding agents

Other caractherics:

•It does not absorb or retain moisture.

•It is not affected by mould, insects or rodents.

•It does not cause irritation to the skin or the mucous membranes.

Polyurethane Foam (Upholstered Furniture)

Furniture made produced with Polyurethane foam injected. The foam has high resilience and durability. The flex-

ible Polyurethane foam is covered with a elastic cellular net that keeps the original poduct’s shape after its use.

Prevents fungal and bacterial growth.

Mechanical properties.

- Tensile strength resistance: between 3 & 10 (Kp./cm2)

- Compression resistance: between 1,5 & 9 (Kp./cm2)

- Shear strength resistance: between 1 & 5 (Kp./cm2)

- Modulus of elasticity: between 40 & 200 (Kp./cm2)

Table Tops / Features

HPL / Solid Core

HPL Tabletops for Mari-sol, Faz and Delta table bases thickness is 10mm ± 0,55.

Thickness

ISO 4586 ½

mm

13 ± 0,55

Density

ISO 1183

Kg/m3

1400 - 1500

Absorción de agua

ISO 4586 ½

%

Weight

2,0 max.

Thickness

2,0 max.

Estabilidad dimensional a altas

temperaturas

ISO 4586 ½

%

Long.

0,25 max.

Trans.

0,55 max.

Hardness

ASTM D 785

HR E

97 ca

Resistencia a la flexión

ISO 178

MPa

MPa

Long.

145 min

Trans

135 min

Glass

Security tempered glass. Thickness: 10 mm.

Technical Features

Units

Value

Resistant to soft body impact

2(B)2

Resistance against suddne temperature changes

K

40

Resistant to wind, snow and large weight

mm

10

Sound insulation

dB

34 (-1,-3)

Thermal Properties

Thermal Transmittance (value U)

W/(m2,K)

5.6

Light Transmission tV

0.53

Light Refletion pV

0.06/0.06

Solar Transmission tE

0.52

Solar Reflection pE

0.06/0.06

DEKTON®

Ceramic surface with high resistance, suitable for indoor and outdoor use.

Kelya

Entzo

Danae

Flexural tensile strength

or modulus of rupture

UNE EN ISO

10545-4

Average flexural

resistance

N/mm2

46

45

55

Average break load

N

2548

2313

2356

Average break strength

N

14966

13559

13818

Water absorption,

apparent porosity,

density

UNE EN ISO

10545-3

Water absroption by

boiling

%

0

0,1

0,1

Water absortion by

vacuum

%

0,1

0,1

0,1

Open porosity

%

0,2

0,2

0,2

Aparent relative

density

g/cm3

2,51

2,61

2,53

Aparent density

g/cm3

2,50

2,61

2,52

Resistance to deep

abrasion

UNE EN ISO

10545-6

Wear volume

mm3

125

106

115

Impact resistance

UNE EN ISO

10545-5

Coefficient of restitu-

tion (COR)

-

0,85

0,85

0,85

Determination of linear

thermal expansion

UNE EN ISO

10545-8

Expansion 30-100ºC

ºC-1

6,5 · 10-6

5,1 ·

10-6

6,3 ·

10-6

Thermal shock

resistance

UNE EN ISO

10545-9

Damage

-

ULA (no

damage)

ULA (no

damage)

ULA (no

damage)

Moisture expansion

UNE EN ISO

10545-10

Expansion max

mm/m

0,1

0,1

0,1

Expansion mid

mm/m

0,0

0,0

0,0

Frost resistance

UNE EN ISO

10545-12

Damage

-

ULA (no

damage)

ULA (no

damage)

ULA (no

damage)

EN | Technical Information