Serdaneli

16

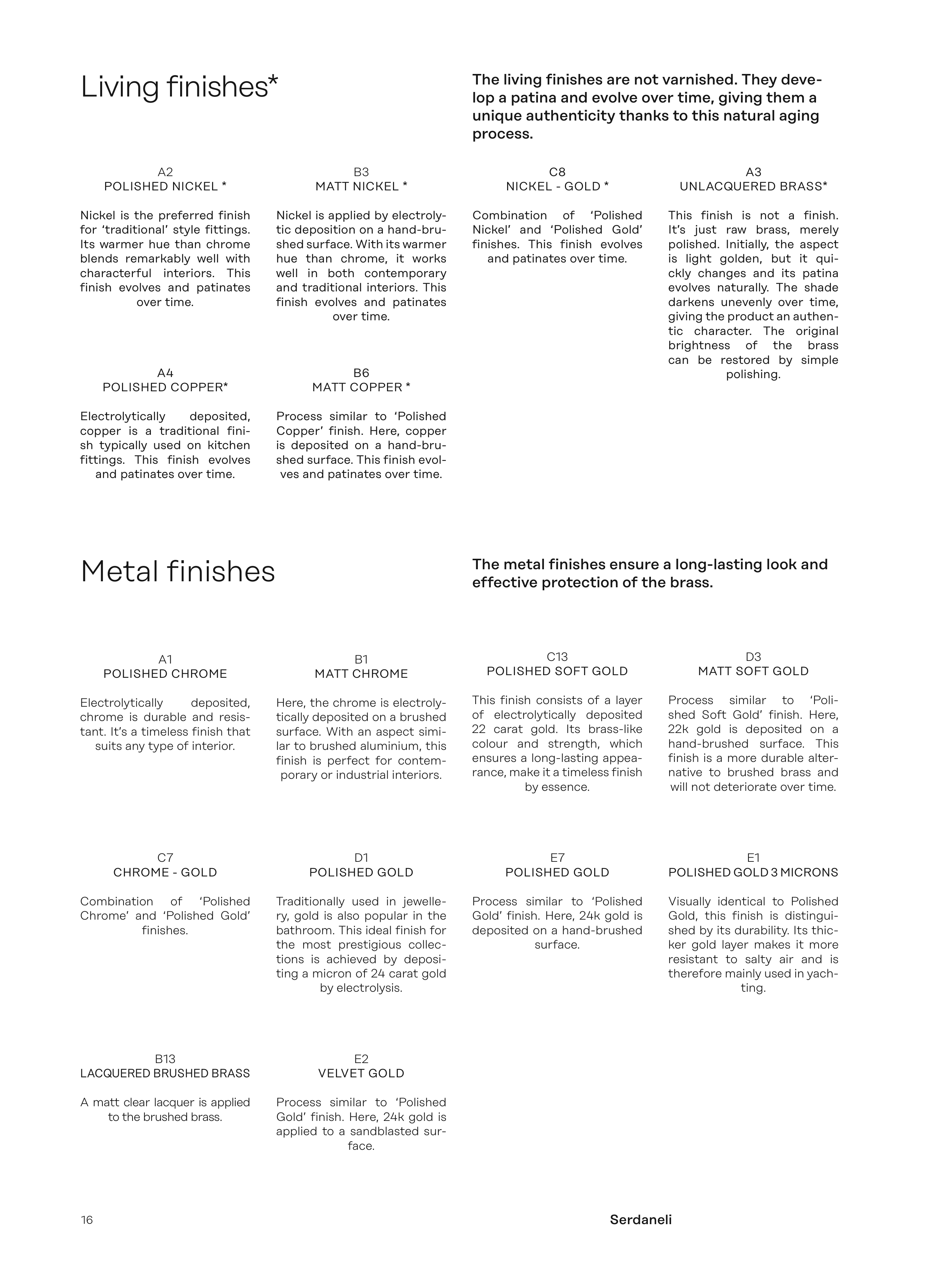

E2

VELVET GOLD

Process similar to ‘Polished

Gold’ finish. Here, 24k gold is

applied to a sandblasted sur-

face.

C7

CHROME - GOLD

Combination

of

‘Polished

Chrome’ and ‘Polished Gold’

finishes.

D1

POLISHED GOLD

Traditionally used in jewelle-

ry, gold is also popular in the

bathroom. This ideal finish for

the most prestigious collec-

tions is achieved by deposi-

ting a micron of 24 carat gold

by electrolysis.

C13

POLISHED SOFT GOLD

This finish consists of a layer

of electrolytically deposited

22 carat gold. Its brass-like

colour and strength, which

ensures a long-lasting appea-

rance, make it a timeless finish

by essence.

D3

MATT SOFT GOLD

Process

similar

to

‘Poli-

shed Soft Gold’ finish. Here,

22k gold is deposited on a

hand-brushed surface. This

finish is a more durable alter-

native to brushed brass and

will not deteriorate over time.

E1

POLISHED GOLD 3 MICRONS

Visually identical to Polished

Gold, this finish is distingui-

shed by its durability. Its thic-

ker gold layer makes it more

resistant to salty air and is

therefore mainly used in yach-

ting.

B1

MATT CHROME

Here, the chrome is electroly-

tically deposited on a brushed

surface. With an aspect simi-

lar to brushed aluminium, this

finish is perfect for contem-

porary or industrial interiors.

E7

POLISHED GOLD

Process similar to ‘Polished

Gold’ finish. Here, 24k gold is

deposited on a hand-brushed

surface.

A1

POLISHED CHROME

Electrolytically

deposited,

chrome is durable and resis-

tant. It’s a timeless finish that

suits any type of interior.

B13

LACQUERED BRUSHED BRASS

A matt clear lacquer is applied

to the brushed brass.

B6

MATT COPPER *

Process similar to ‘Polished

Copper’ finish. Here, copper

is deposited on a hand-bru-

shed surface. This finish evol-

ves and patinates over time.

B3

MATT NICKEL *

Nickel is applied by electroly-

tic deposition on a hand-bru-

shed surface. With its warmer

hue than chrome, it works

well in both contemporary

and traditional interiors. This

finish evolves and patinates

over time.

C8

NICKEL - GOLD *

Combination

of

‘Polished

Nickel’ and ‘Polished Gold’

finishes. This finish evolves

and patinates over time.

A4

POLISHED COPPER*

Electrolytically

deposited,

copper is a traditional fini-

sh typically used on kitchen

fittings. This finish evolves

and patinates over time.

A2

POLISHED NICKEL *

Nickel is the preferred finish

for ‘traditional’ style fittings.

Its warmer hue than chrome

blends remarkably well with

characterful interiors. This

finish evolves and patinates

over time.

A3

UNLACQUERED BRASS*

This finish is not a finish.

It’s just raw brass, merely

polished. Initially, the aspect

is light golden, but it qui-

ckly changes and its patina

evolves naturally. The shade

darkens unevenly over time,

giving the product an authen-

tic character. The original

brightness

of

the

brass

can be restored by simple

polishing.

The metal finishes ensure a long-lasting look and

effective protection of the brass.

The living finishes are not varnished. They deve-

lop a patina and evolve over time, giving them a

unique authenticity thanks to this natural aging

process.

Metal finishes

Living finishes*