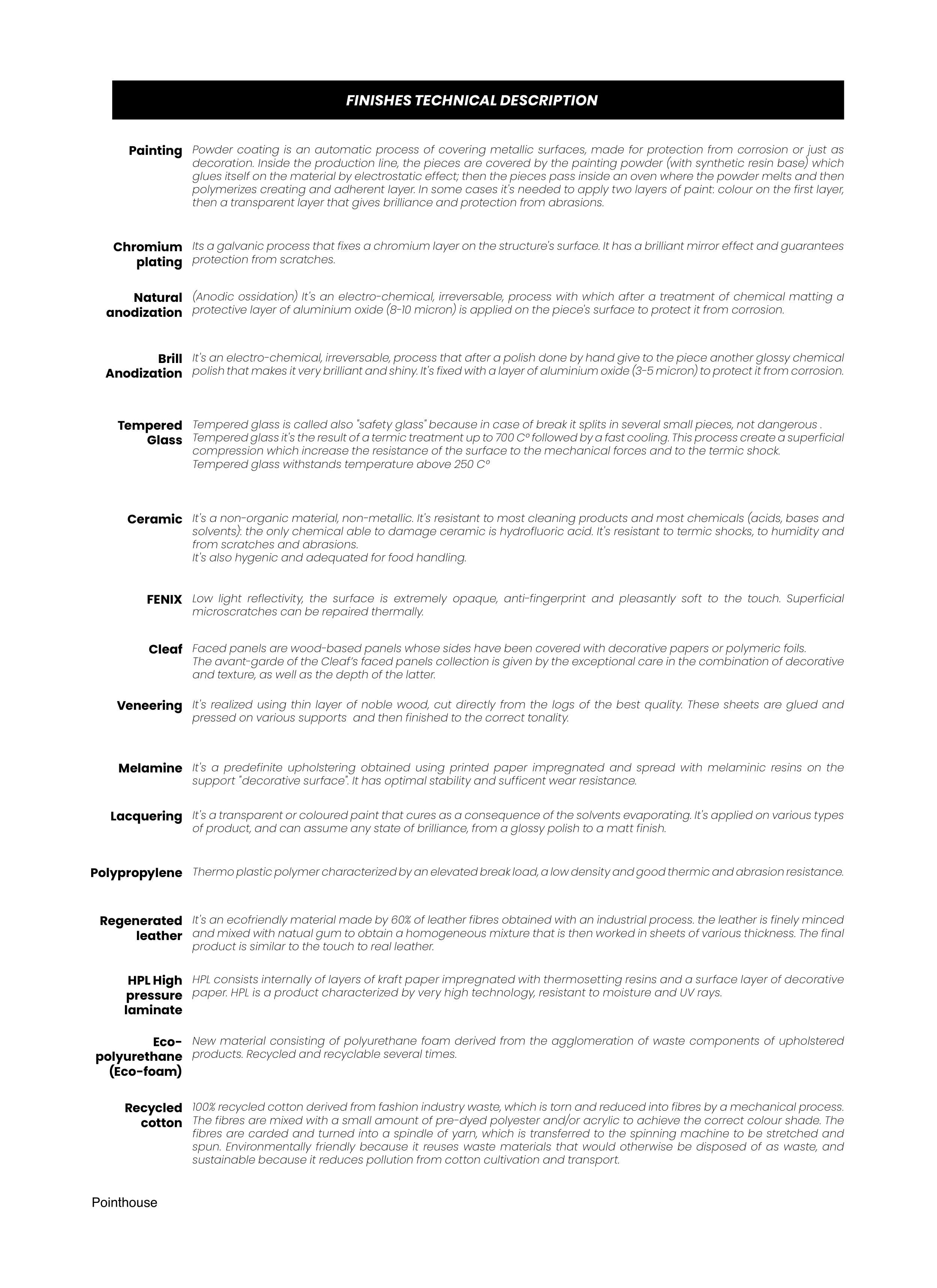

FINISHES TECHNICAL DESCRIPTION

Tempered

Glass

Tempered glass is called also "safety glass" because in case of break it splits in several small pieces, not dangerous .

Tempered glass it's the result of a termic treatment up to 700 C° followed by a fast cooling. This process create a superficial

compression which increase the resistance of the surface to the mechanical forces and to the termic shock.

Tempered glass withstands temperature above 250 C°

Painting

Powder coating is an automatic process of covering metallic surfaces, made for protection from corrosion or just as

decoration. Inside the production line, the pieces are covered by the painting powder (with synthetic resin base) which

glues itself on the material by electrostatic effect; then the pieces pass inside an oven where the powder melts and then

polymerizes creating and adherent layer. In some cases it's needed to apply two layers of paint: colour on the first layer,

then a transparent layer that gives brilliance and protection from abrasions.

Chromium

plating

Its a galvanic process that fixes a chromium layer on the structure's surface. It has a brilliant mirror effect and guarantees

protection from scratches.

Natural

anodization

(Anodic ossidation) It's an electro-chemical, irreversable, process with which after a treatment of chemical matting a

protective layer of aluminium oxide (8-10 micron) is applied on the piece's surface to protect it from corrosion.

Brill

Anodization

It's an electro-chemical, irreversable, process that after a polish done by hand give to the piece another glossy chemical

polish that makes it very brilliant and shiny. It's fixed with a layer of aluminium oxide (3-5 micron) to protect it from corrosion.

Lacquering

It's a transparent or coloured paint that cures as a consequence of the solvents evaporating. It's applied on various types

of product, and can assume any state of brilliance, from a glossy polish to a matt finish.

Veneering

It's realized using thin layer of noble wood, cut directly from the logs of the best quality. These sheets are glued and

pressed on various supports and then finished to the correct tonality.

Melamine

It's a predefinite upholstering obtained using printed paper impregnated and spread with melaminic resins on the

support "decorative surface". It has optimal stability and sufficent wear resistance.

Regenerated

leather

It's an ecofriendly material made by 60% of leather fibres obtained with an industrial process. the leather is finely minced

and mixed with natual gum to obtain a homogeneous mixture that is then worked in sheets of various thickness. The final

product is similar to the touch to real leather.

Ceramic

It's a non-organic material, non-metallic. It's resistant to most cleaning products and most chemicals (acids, bases and

solvents): the only chemical able to damage ceramic is hydrofluoric acid. It's resistant to termic shocks, to humidity and

from scratches and abrasions.

It's also hygenic and adequated for food handling.

FENIX

Low light reflectivity, the surface is extremely opaque, anti-fingerprint and pleasantly soft to the touch. Superficial

microscratches can be repaired thermally.

Cleaf

Faced panels are wood-based panels whose sides have been covered with decorative papers or polymeric foils.

The avant-garde of the Cleaf’s faced panels collection is given by the exceptional care in the combination of decorative

and texture, as well as the depth of the latter.

HPL High

pressure

laminate

HPL consists internally of layers of kraft paper impregnated with thermosetting resins and a surface layer of decorative

paper. HPL is a product characterized by very high technology, resistant to moisture and UV rays.

Polypropylene

Thermo plastic polymer characterized by an elevated break load, a low density and good thermic and abrasion resistance.

Eco-

polyurethane

(Eco-foam)

Recycled

cotton

100% recycled cotton derived from fashion industry waste, which is torn and reduced into fibres by a mechanical process.

The fibres are mixed with a small amount of pre-dyed polyester and/or acrylic to achieve the correct colour shade. The

fibres are carded and turned into a spindle of yarn, which is transferred to the spinning machine to be stretched and

spun. Environmentally friendly because it reuses waste materials that would otherwise be disposed of as waste, and

sustainable because it reduces pollution from cotton cultivation and transport.

New material consisting of polyurethane foam derived from the agglomeration of waste components of upholstered

products. Recycled and recyclable several times.