62

63

We are fortunate to work with design partners we

admire, both personally and professionally. Each brings

personality, vibrancy, and their own particular way of

working, collectively playing a role in defining the diverse

yet constant aesthetic of De La Espada. Each collaboration

is unique, yet all require close communication in order

to harness the unique skills of each partner and work

toward a common vision. Key to this process is our product

development team.

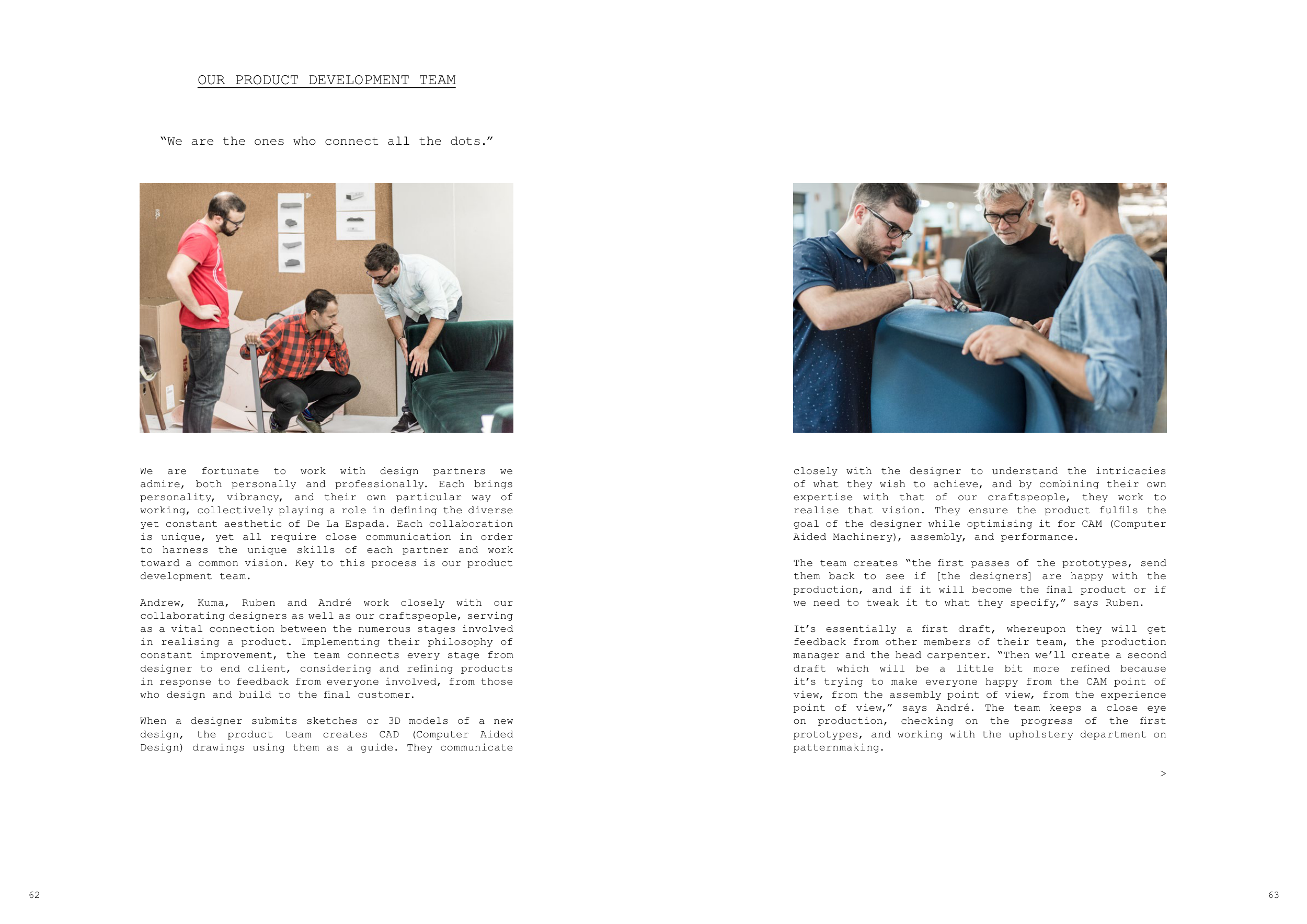

Andrew, Kuma, Ruben and André work closely with our

collaborating designers as well as our craftspeople, serving

as a vital connection between the numerous stages involved

in realising a product. Implementing their philosophy of

constant improvement, the team connects every stage from

designer to end client, considering and refining products

in response to feedback from everyone involved, from those

who design and build to the final customer.

When a designer submits sketches or 3D models of a new

design, the product team creates CAD (Computer Aided

Design) drawings using them as a guide. They communicate

OUR PRODUCT DEVELOPMENT TEAM

closely with the designer to understand the intricacies

of what they wish to achieve, and by combining their own

expertise with that of our craftspeople, they work to

realise that vision. They ensure the product fulfils the

goal of the designer while optimising it for CAM (Computer

Aided Machinery), assembly, and performance.

The team creates “the first passes of the prototypes, send

them back to see if [the designers] are happy with the

production, and if it will become the final product or if

we need to tweak it to what they specify,” says Ruben.

It’s essentially a first draft, whereupon they will get

feedback from other members of their team, the production

manager and the head carpenter. “Then we’ll create a second

draft which will be a little bit more refined because

it’s trying to make everyone happy from the CAM point of

view, from the assembly point of view, from the experience

point of view,” says André. The team keeps a close eye

on production, checking on the progress of the first

prototypes, and working with the upholstery department on

patternmaking.

>

“We are the ones who connect all the dots.”