64

65

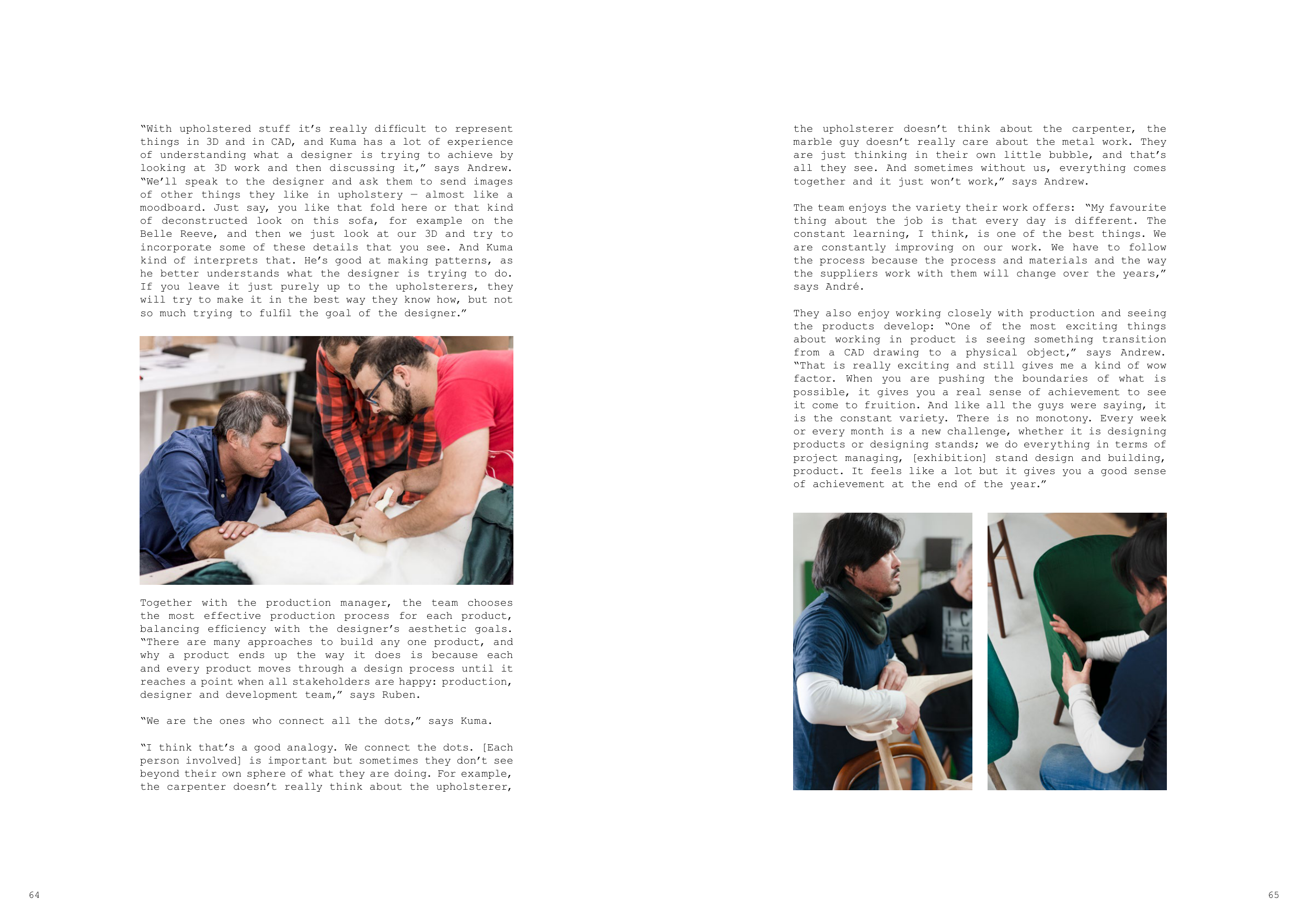

“With upholstered stuff it’s really difficult to represent

things in 3D and in CAD, and Kuma has a lot of experience

of understanding what a designer is trying to achieve by

looking at 3D work and then discussing it,” says Andrew.

“We’ll speak to the designer and ask them to send images

of other things they like in upholstery — almost like a

moodboard. Just say, you like that fold here or that kind

of deconstructed look on this sofa, for example on the

Belle Reeve, and then we just look at our 3D and try to

incorporate some of these details that you see. And Kuma

kind of interprets that. He’s good at making patterns, as

he better understands what the designer is trying to do.

If you leave it just purely up to the upholsterers, they

will try to make it in the best way they know how, but not

so much trying to fulfil the goal of the designer.”

Together with the production manager, the team chooses

the most effective production process for each product,

balancing efficiency with the designer’s aesthetic goals.

“There are many approaches to build any one product, and

why a product ends up the way it does is because each

and every product moves through a design process until it

reaches a point when all stakeholders are happy: production,

designer and development team,” says Ruben.

“We are the ones who connect all the dots,” says Kuma.

“I think that’s a good analogy. We connect the dots. [Each

person involved] is important but sometimes they don’t see

beyond their own sphere of what they are doing. For example,

the carpenter doesn’t really think about the upholsterer,

the upholsterer doesn’t think about the carpenter, the

marble guy doesn’t really care about the metal work. They

are just thinking in their own little bubble, and that’s

all they see. And sometimes without us, everything comes

together and it just won’t work,” says Andrew.

The team enjoys the variety their work offers: “My favourite

thing about the job is that every day is different. The

constant learning, I think, is one of the best things. We

are constantly improving on our work. We have to follow

the process because the process and materials and the way

the suppliers work with them will change over the years,”

says André.

They also enjoy working closely with production and seeing

the products develop: “One of the most exciting things

about working in product is seeing something transition

from a CAD drawing to a physical object,” says Andrew.

“That is really exciting and still gives me a kind of wow

factor. When you are pushing the boundaries of what is

possible, it gives you a real sense of achievement to see

it come to fruition. And like all the guys were saying, it

is the constant variety. There is no monotony. Every week

or every month is a new challenge, whether it is designing

products or designing stands; we do everything in terms of

project managing, [exhibition] stand design and building,

product. It feels like a lot but it gives you a good sense

of achievement at the end of the year.”