C 05 51

National Science Foundation, and the National Aeronautics and

Space Administration (NASA), Khoshnevis is experimenting with a

3D printing process called “contour crafting” to print buildings. He

has created a form-free composite-fiber concrete that can be extruded

and that is strong enough to allow a printed wall to support itself

during construction.

Khoshnevis is not alone. The MIT research lab is using 3D printing

to explore ways to create the frame of a house in one day with virtually

no human labor. That same frame would take an entire construction

crew a month to put up.

Dini and Foster + Partners, one of the world’s largest architectural

firms, have teamed up with the European Space Agency to explore

the possibility of using 3D printing to construct a permanent base

on the moon. The buildings would be printed using lunar soil as the

feedstock. The goal is to construct lunar habitats with locally sustain-

able materials found on the moon in order to avoid the logistical cost

of shipping in materials from Earth.

While the 3D printing of buildings is in the very early stages of

development, it is projected to grow exponentially in the coming two

decades as the production process becomes increasingly efficient and

cheaper. Unlike conventional construction techniques, where the cost

of designing architectural blueprints is high, construction materials

are expensive, labor costs are steep, and the time necessary to erect

the structures is lengthy, 3D printing is not affected by these factors.

Whether on the moon or here on Earth, human beings will need

transport to get around. The first 3D-printed automobile, the Urbee,

is already being field tested. The Urbee was developed by KOR Eco-

Logic, a company based in Winnipeg, Canada. The automobile is a

two-passenger hybrid-electric vehicle, which is designed to run on

solar and wind power that can be harvested in a one-car garage each

day. The car can reach speeds of 40 miles per hour. If long driving

distances are necessary, the user can switch over to the car’s ethanol-

powered backup engine. Granted, the Urbee is just the first working

prototype of the new TIR-era automobile, but like the introduction of

Henry Ford’s first mass-produced, gas-powered internal-combustion

engine automobile, the nature of the vehicle’s construction and power

source is highly suggestive of the kind of future it portends for the

economy and society.

A 3D-printed automobile is produced with a very different logic. The

automobile can be made from nearly free feedstock available locally,

eliminating the high cost of rare materials and the costs of shipping

them to the factory and storing them on-site. Most of the parts in the

car are made with 3D-printed plastic, with the exception of the base

chassis and engine. The rest of the car is produced in layers, which

are “added” one onto another in a continuous flow rather than being

assembled together from individual parts, meaning less material, less

time, and less labor are used. A six-foot-high 3D printer poured out

Urbee’s shell in only ten pieces, with no wasted material.

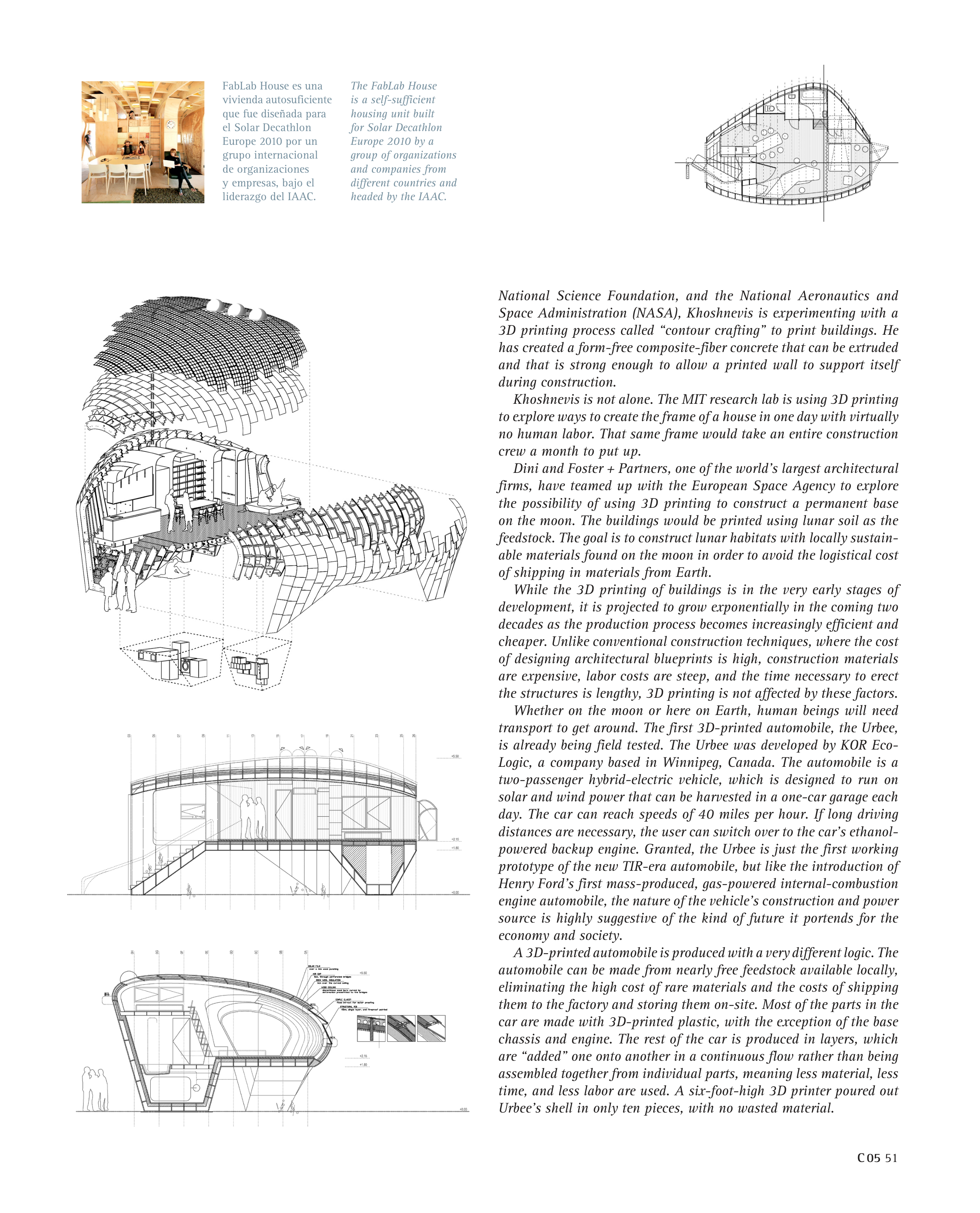

FabLab House es una

vivienda autosuficiente

que fue diseñada para

el Solar Decathlon

Europe 2010 por un

grupo internacional

de organizaciones

y empresas, bajo el

liderazgo del IAAC.

The FabLab House

is a self-sufficient

housing unit built

for Solar Decathlon

Europe 2010 by a

group of organizations

and companies from

different countries and

headed by the IAAC.