Sorting foam — The foam

determines the comfort of

your furniture. Every model

therefore has a specific

mix of different foam

densities so that you sit

comfortably. All the foam

parts are cut to order. They

are then sorted per order

and delivered as parcels to

the production.

Frame construction —

Wood is a lovely, natural

construction material,

which we have enjoyed

using for over 90 years.

Our totally new computer-

controlled woodworking

department makes all the

wooden parts to order.

This means we only use the

material that is required

for the furniture. The

frame constructors put

all the parts together to

create a solid, sustainable

structure.

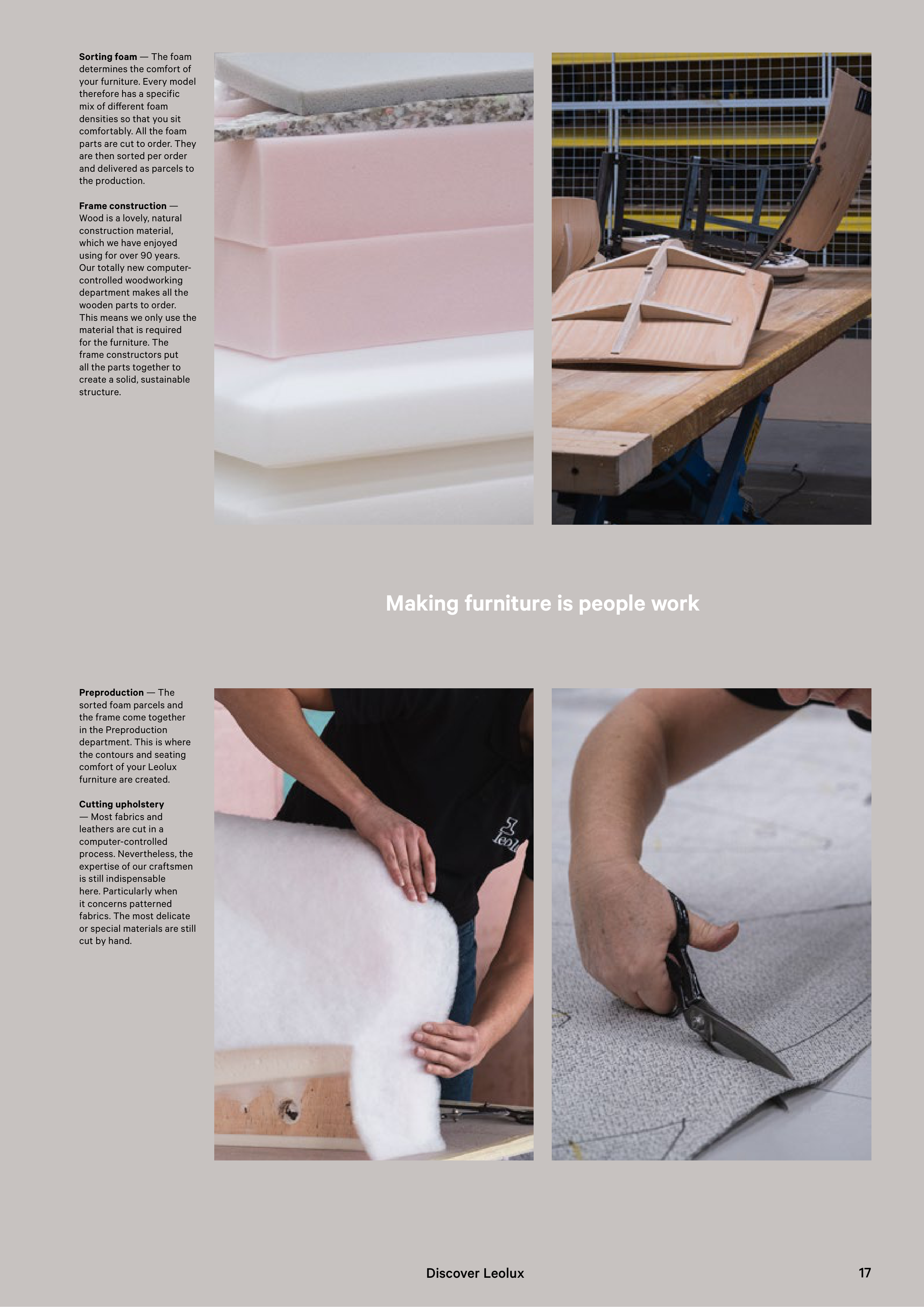

Preproduction — The

sorted foam parcels and

the frame come together

in the Preproduction

department. This is where

the contours and seating

comfort of your Leolux

furniture are created.

Cutting upholstery

— Most fabrics and

leathers are cut in a

computer-controlled

process. Nevertheless, the

expertise of our craftsmen

is still indispensable

here. Particularly when

it concerns patterned

fabrics. The most delicate

or special materials are still

cut by hand.

Making furniture is people work

17

Discover Leolux