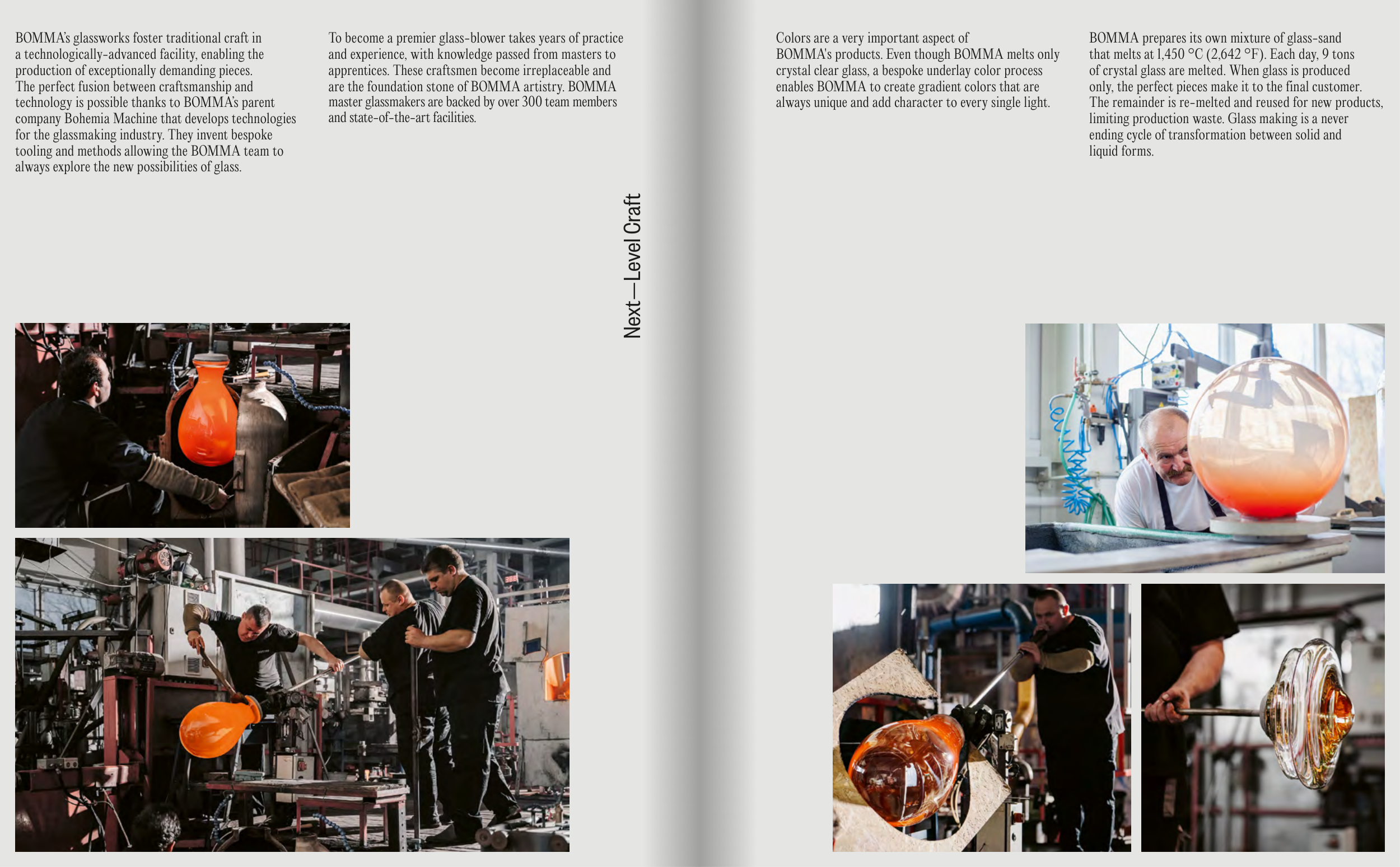

BOMMA’s glassworks foster traditional craft in

a technologically-advanced facility, enabling the

production of exceptionally demanding pieces.

The perfect fusion between craftsmanship and

technology is possible thanks to BOMMA’s parent

company Bohemia Machine that develops technologies

for the glassmaking industry. They invent bespoke

tooling and methods allowing the BOMMA team to

always explore the new possibilities of glass.

Colors are a very important aspect of

BOMMA's products. Even though BOMMA melts only

crystal clear glass, a bespoke underlay color process

enables BOMMA to create gradient colors that are

always unique and add character to every single light.

To become a premier glass-blower takes years of practice

and experience, with knowledge passed from masters to

apprentices. These craftsmen become irreplaceable and

are the foundation stone of BOMMA artistry. BOMMA

master glassmakers are backed by over 300 team members

and state-of-the-art facilities.

BOMMA prepares its own mixture of glass-sand

that melts at 1,450 °C (2,642 °F). Each day, 9 tons

of crystal glass are melted. When glass is produced

only, the perfect pieces make it to the final customer.

The remainder is re-melted and reused for new products,

limiting production waste. Glass making is a never

ending cycle of transformation between solid and

liquid forms.

Level Craft

Next