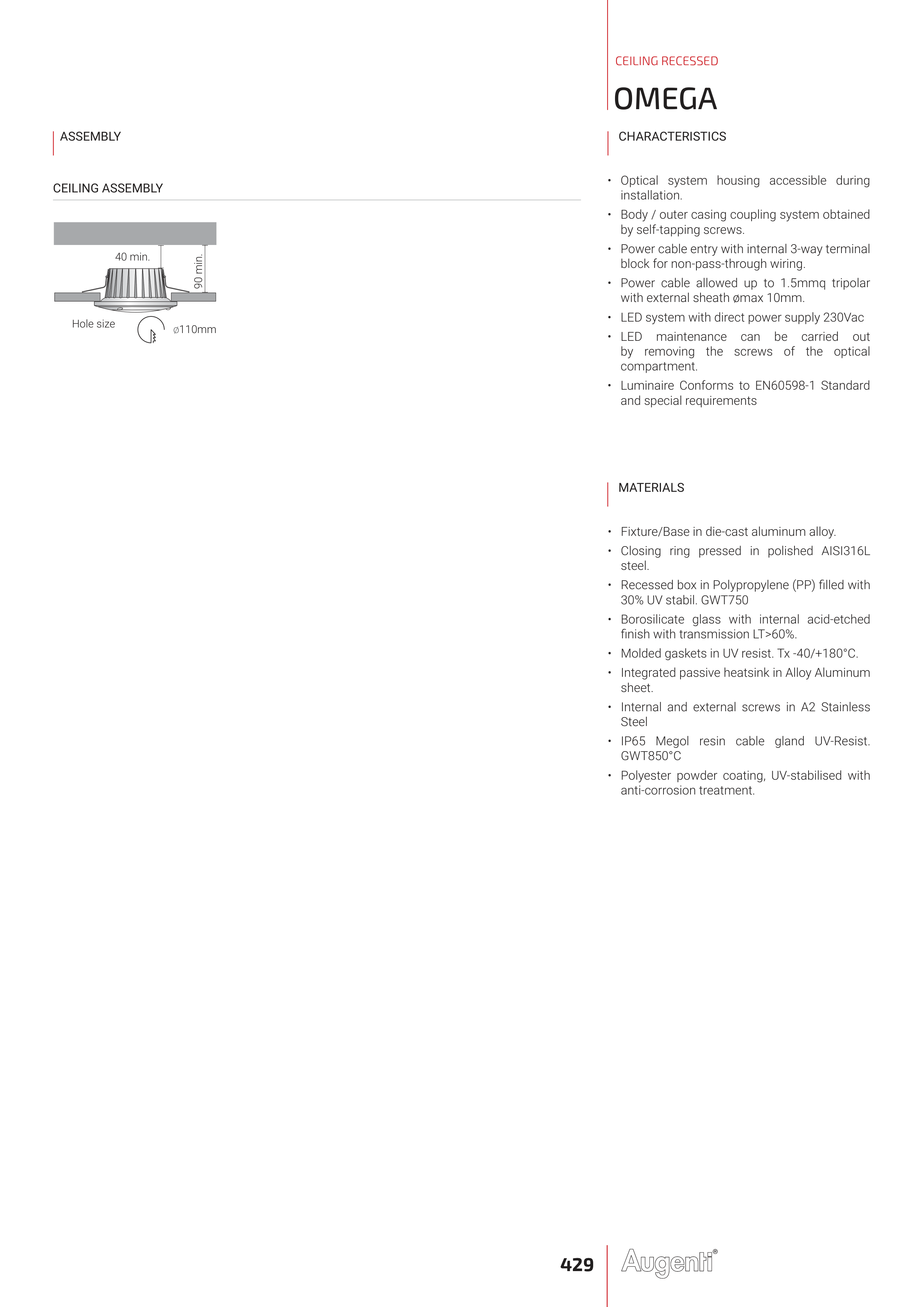

ASSEMBLY

ø110mm

Hole size

90 min.

40 min.

CEILING ASSEMBLY

MATERIALS

CHARACTERISTICS

• Optical system housing accessible during

installation.

• Body / outer casing coupling system obtained

by self-tapping screws.

• Power cable entry with internal 3-way terminal

block for non-pass-through wiring.

• Power cable allowed up to 1.5mmq tripolar

with external sheath ømax 10mm.

• LED system with direct power supply 230Vac

• LED

maintenance

can

be

carried

out

by removing the screws of the optical

compartment.

• Luminaire Conforms to EN60598-1 Standard

and special requirements

• Fixture/Base in die-cast aluminum alloy.

• Closing ring pressed in polished AISI316L

steel.

• Recessed box in Polypropylene (PP) filled with

30% UV stabil. GWT750

• Borosilicate glass with internal acid-etched

finish with transmission LT>60%.

• Molded gaskets in UV resist. Tx -40/+180°C.

• Integrated passive heatsink in Alloy Aluminum

sheet.

• Internal and external screws in A2 Stainless

Steel

• IP65 Megol resin cable gland UV-Resist.

GWT850°C

• Polyester powder coating, UV-stabilised with

anti-corrosion treatment.

OMEGA

429

CEILING RECESSED

429