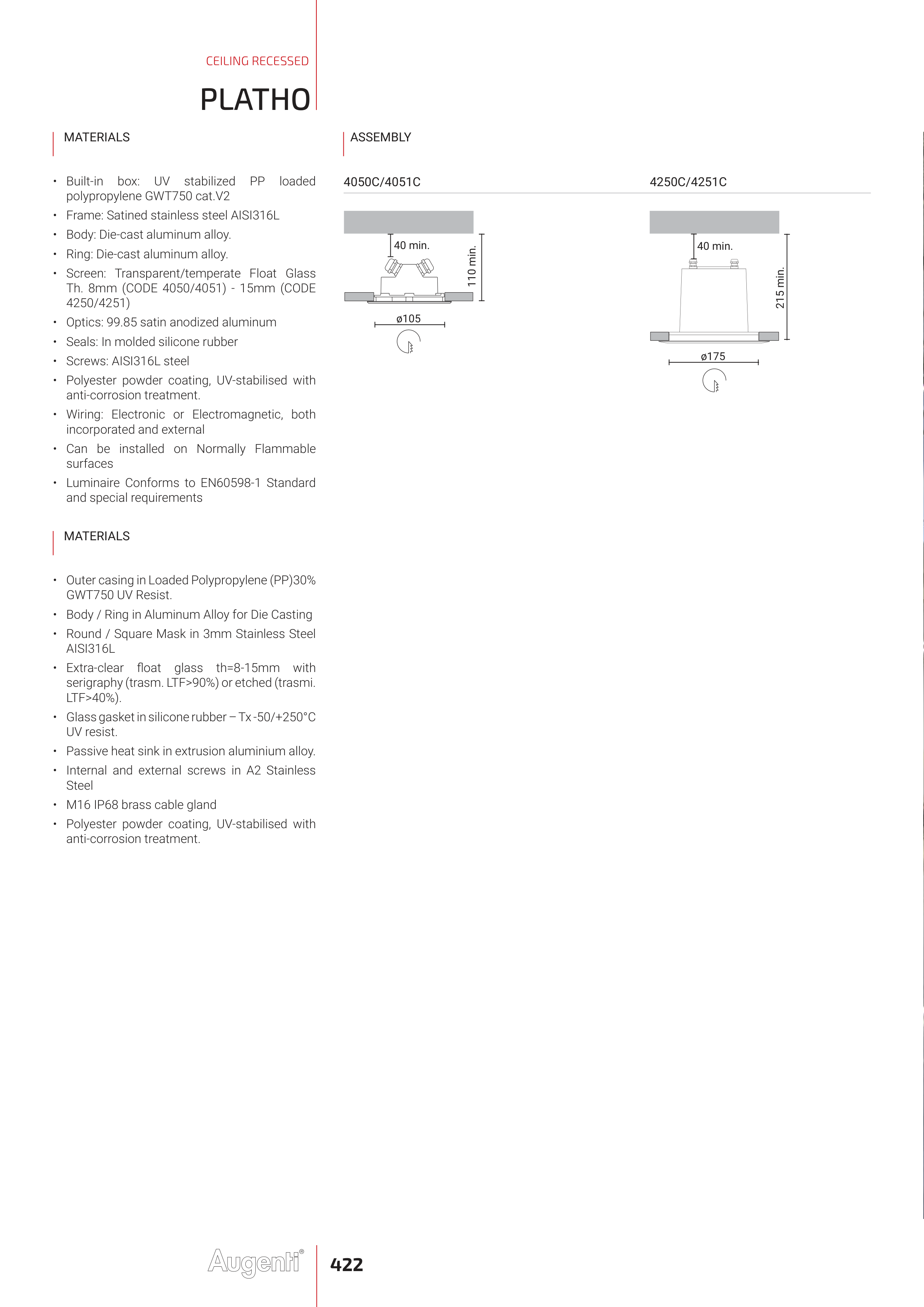

4050C/4051C

ASSEMBLY

4250C/4251C

110 min.

ø105

40 min.

215 min.

ø175

40 min.

MATERIALS

• Built-in

box:

UV

stabilized

PP

loaded

polypropylene GWT750 cat.V2

• Frame: Satined stainless steel AISI316L

• Body: Die-cast aluminum alloy.

• Ring: Die-cast aluminum alloy.

• Screen: Transparent/temperate Float Glass

Th. 8mm (CODE 4050/4051) - 15mm (CODE

4250/4251)

• Optics: 99.85 satin anodized aluminum

• Seals: In molded silicone rubber

• Screws: AISI316L steel

• Polyester powder coating, UV-stabilised with

anti-corrosion treatment.

• Wiring: Electronic or Electromagnetic, both

incorporated and external

• Can be installed on Normally Flammable

surfaces

• Luminaire Conforms to EN60598-1 Standard

and special requirements

MATERIALS

• Outer casing in Loaded Polypropylene (PP)30%

GWT750 UV Resist.

• Body / Ring in Aluminum Alloy for Die Casting

• Round / Square Mask in 3mm Stainless Steel

AISI316L

• Extra-clear

float

glass

th=8-15mm

with

serigraphy (trasm. LTF>90%) or etched (trasmi.

LTF>40%).

• Glass gasket in silicone rubber – Tx -50/+250°C

UV resist.

• Passive heat sink in extrusion aluminium alloy.

• Internal and external screws in A2 Stainless

Steel

• M16 IP68 brass cable gland

• Polyester powder coating, UV-stabilised with

anti-corrosion treatment.

422

CEILING RECESSED

PLATHO