0° C

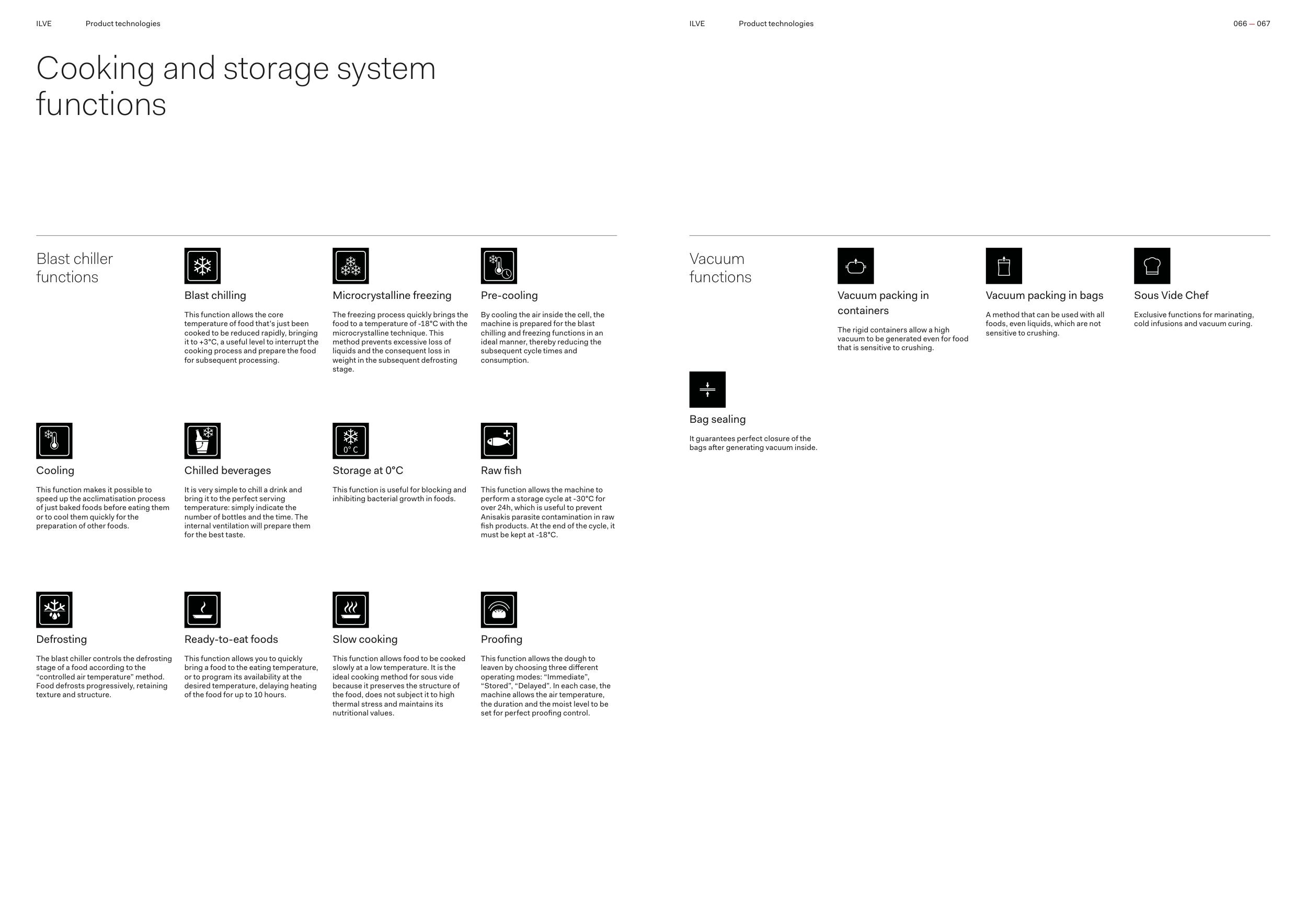

Cooking and storage system

functions

Vacuum

functions

Blast chiller

functions

Vacuum packing in

containers

The rigid containers allow a high

vacuum to be generated even for food

that is sensitive to crushing.

Vacuum packing in bags

A method that can be used with all

foods, even liquids, which are not

sensitive to crushing.

Bag sealing

It guarantees perfect closure of the

bags after generating vacuum inside.

Blast chilling

This function allows the core

temperature of food that’s just been

cooked to be reduced rapidly, bringing

it to +3°C, a useful level to interrupt the

cooking process and prepare the food

for subsequent processing.

Chilled beverages

It is very simple to chill a drink and

bring it to the perfect serving

temperature: simply indicate the

number of bottles and the time. The

internal ventilation will prepare them

for the best taste.

Ready-to-eat foods

This function allows you to quickly

bring a food to the eating temperature,

or to program its availability at the

desired temperature, delaying heating

of the food for up to 10 hours.

Cooling

This function makes it possible to

speed up the acclimatisation process

of just baked foods before eating them

or to cool them quickly for the

preparation of other foods.

Defrosting

The blast chiller controls the defrosting

stage of a food according to the

“controlled air temperature” method.

Food defrosts progressively, retaining

texture and structure.

Microcrystalline freezing

The freezing process quickly brings the

food to a temperature of -18°C with the

microcrystalline technique. This

method prevents excessive loss of

liquids and the consequent loss in

weight in the subsequent defrosting

stage.

Storage at 0°C

This function is useful for blocking and

inhibiting bacterial growth in foods.

Slow cooking

This function allows food to be cooked

slowly at a low temperature. It is the

ideal cooking method for sous vide

because it preserves the structure of

the food, does not subject it to high

thermal stress and maintains its

nutritional values.

Pre-cooling

By cooling the air inside the cell, the

machine is prepared for the blast

chilling and freezing functions in an

ideal manner, thereby reducing the

subsequent cycle times and

consumption.

Raw fish

This function allows the machine to

perform a storage cycle at -30°C for

over 24h, which is useful to prevent

Anisakis parasite contamination in raw

fish products. At the end of the cycle, it

must be kept at -18°C.

Proofing

This function allows the dough to

leaven by choosing three different

operating modes: “Immediate”,

“Stored”, “Delayed”. In each case, the

machine allows the air temperature,

the duration and the moist level to be

set for perfect proofing control.

Sous Vide Chef

Exclusive functions for marinating,

cold infusions and vacuum curing.

ILVE

ILVE

066 — 067

Product technologies

Product technologies