198

Making Rugs By Hand

THE JOURNEY

OF A RUG

02

01

05

06

03

04

Having spent years honing their skills to the highest degree, these artisans use time-honoured

techniques to bring our designers’ and clients’ creative visions to life. From spinning, weaving, knotting

and looming to trimming piles on a finished rug, these traditional methods have been passed down

through generations. Our longstanding relationship with the makers means we are continually able to

innovate and expand our capabilities.

Each one of our craftspeople is fundamental to the design process, their exceptional skill ensures that

each rug will last a lifetime.

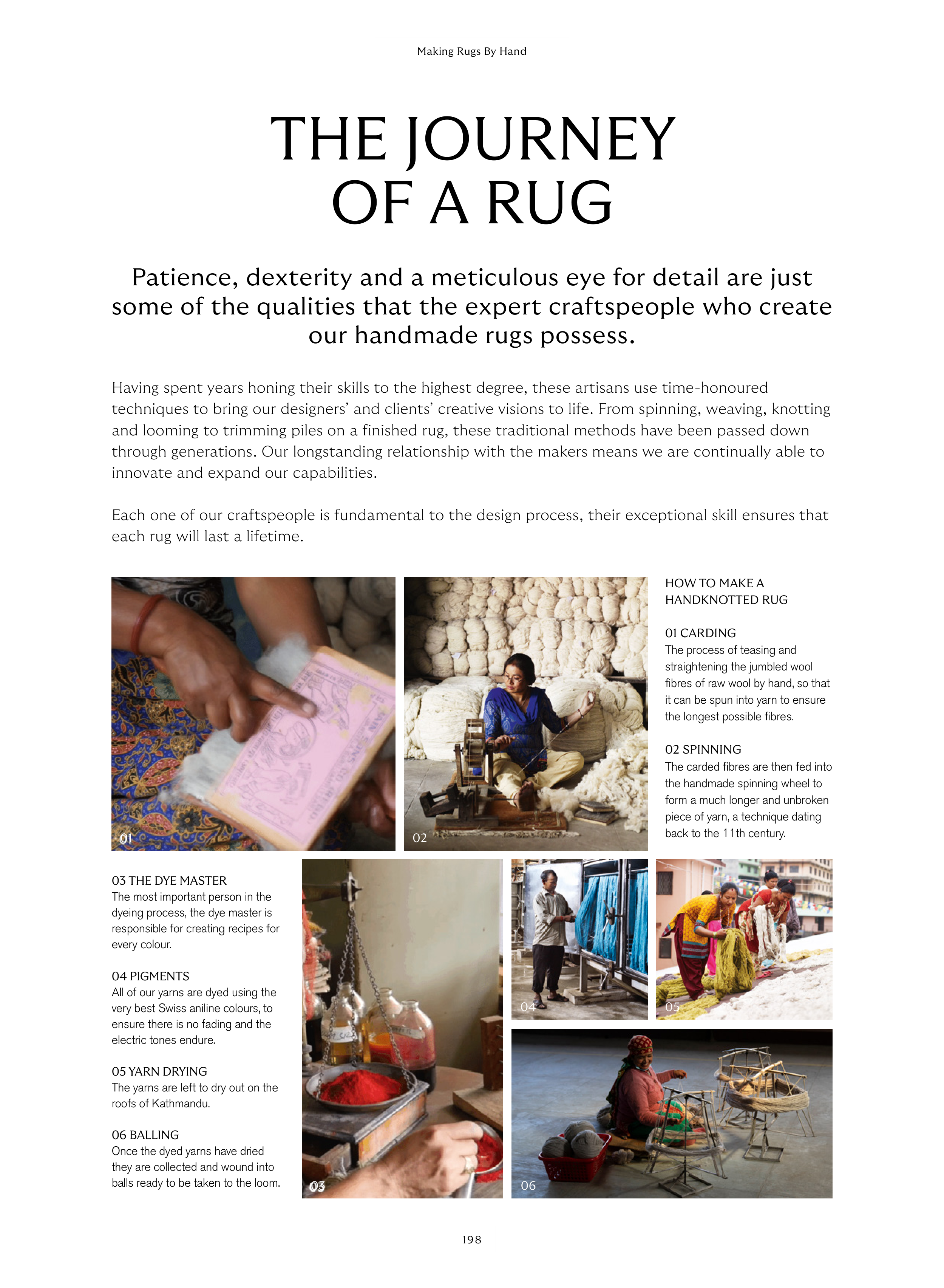

HOW TO MAKE A

HANDKNOTTED RUG

01 CARDING

The process of teasing and

straightening the jumbled wool

fibres of raw wool by hand, so that

it can be spun into yarn to ensure

the longest possible fibres.

02 SPINNING

The carded fibres are then fed into

the handmade spinning wheel to

form a much longer and unbroken

piece of yarn, a technique dating

back to the 11th century.

03 THE DYE MASTER

The most important person in the

dyeing process, the dye master is

responsible for creating recipes for

every colour.

04 PIGMENTS

All of our yarns are dyed using the

very best Swiss aniline colours, to

ensure there is no fading and the

electric tones endure.

05 YARN DRYING

The yarns are left to dry out on the

roofs of Kathmandu.

06 BALLING

Once the dyed yarns have dried

they are collected and wound into

balls ready to be taken to the loom.

Patience, dexterity and a meticulous eye for detail are just

some of the qualities that the expert craftspeople who create

our handmade rugs possess.