141

MITE

MITE 2000

Marc Sadler

The product of over two years of

research work, the Mite floor lamp has

been in production since the year 2000.

Conceived by Marc Sadler, it features a

1,85 meter high shade with a circular

plan; its shape flares towards the top,

and it is made of a woven glass fiber

wrapped in a thread of carbon for the

black version, and kevlar® for the yellow

version. The shaping is done on a mold

which is covered with two pieces of the

glass fabric saturated with a special

transparent resin, around which the

fiber is then wrapped.

The polymerization occurs in a pressure

controlled oven. The idea for the project

came from the selection of the material

and the processing techniques.

“For the Foscarini lamps, says the

designer, I had to pay particular

attention to the historical origins of the

company. Its product has always

enjoyed a specifically Venetian

connotation, because of its work in

Murano glass, with great sensitivity

towards the quality of the material.

Plastic takes almost the opposite

attitude towards the transformation of

material. The intent was to find a

connection between the techniques

used for glass and the material at

hand: in the case in point, I thought of

a system which I had already used for

products of mass distribution, such as

golf clubs, tennis rackets and skis.”

The result which Sadler was aiming at

was to obtain a transparent

unbreakable shade through roving, an

industrial process based on wrapping

carbon fibers, which for Mite were

applied onto a woven

glass fiber fabric and held together

with special resins.

The quantity and position of the thread

determined the degree of transparency

of the material and simultaneously

conferred resistance, flexibility and

lightness by requiring lesser sections.

A manufacturer was found, who usually

applied this technology to fishing rods

and boat oars, and had to adjust his

production processes to satisfy this

request: the greatest effort was in

making sure that in each phase the

reduction of the thickness, that is the

consistency of the layer of composite

material, did not weaken the structure.

Sadler’s initial design, a tall cylinder

flared at each end with an automobile

headlight at the top, presented

execution problems, in that it required

two molds, and during the annealing

process, the thread tended to overlap at

the contact point, and increase the

opacity of the material.

The shape of the current shade

originated in the effort to reduce the

overlay of threads to a minimum, the

narrow end part where the effect is

most obvious was in fact shortened

during the finishing phases.

A determining factor for the overall

luminous effect was also the location of

the light source, a 250 watt halogen

bulb with a dimmer: three metal rods

keep it at a correct distance from the

shade, leaving it suspended from the

upper lip, in order to avoid the shadows

that would have been cast, for example,

by a central support.

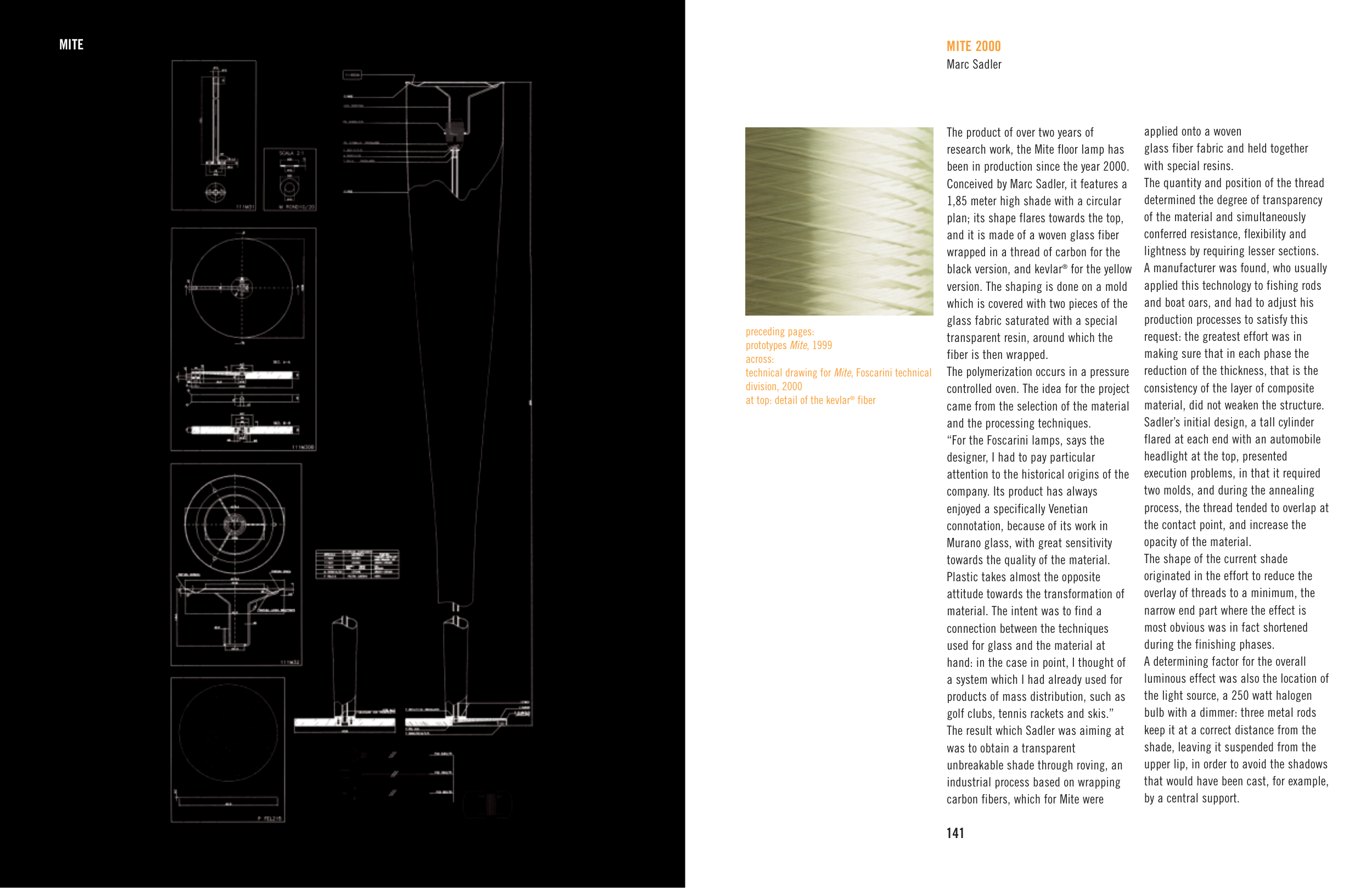

preceding pages:

prototypes Mite, 1999

across:

technical drawing for Mite, Foscarini technical

division, 2000

at top: detail of the kevlar® fiber