090

well to the requirements for a lightweight lamp body, which would have a

non-invasive, almost ethereal physical impact. Over two years of research

was required to make Mite, a lamp produced in the year 2000, with a body

in woven glass fibre wrapped in carbon or kevlar® fiber thread.

To produce a fixture which could adequately transmit the luminous flux, a

suitable construction technology was found – roving – and a mold and

appropriate form were slowly perfected. In recent years the

experimentation of materials and technologies conducted by Foscarini has

become quite significant; it begins with the specific requirements of the

project, developed within a context dedicated to research and

characterized by total freedom to use a variety of productive and

technological resources.

To allow the electric wires, suitably insulated, to pass through the ring-

shaped body of the O-space suspension, high density polyurethane foam

was used, leaving the central circumscribed space totally and suggestively

free; the technology of rotomoulding was experimented to produce Blob;

and stretched metal mesh, covered in transparent silicone resin, served as

both the supporting casing and the shade for the Bague table lamp,

created in 2003.

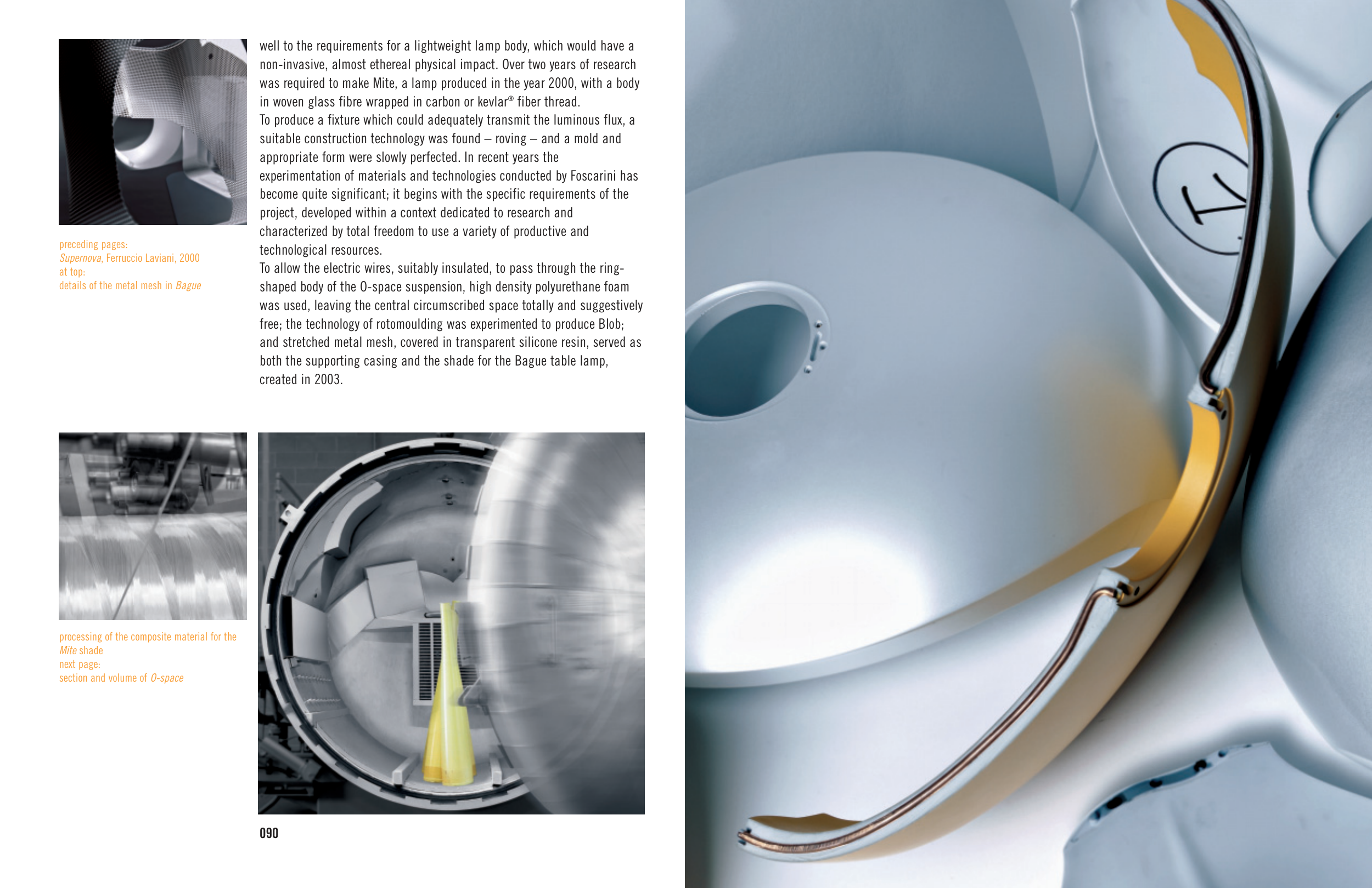

preceding pages:

Supernova, Ferruccio Laviani, 2000

at top:

details of the metal mesh in Bague

processing of the composite material for the

Mite shade

next page:

section and volume of O-space