14

15

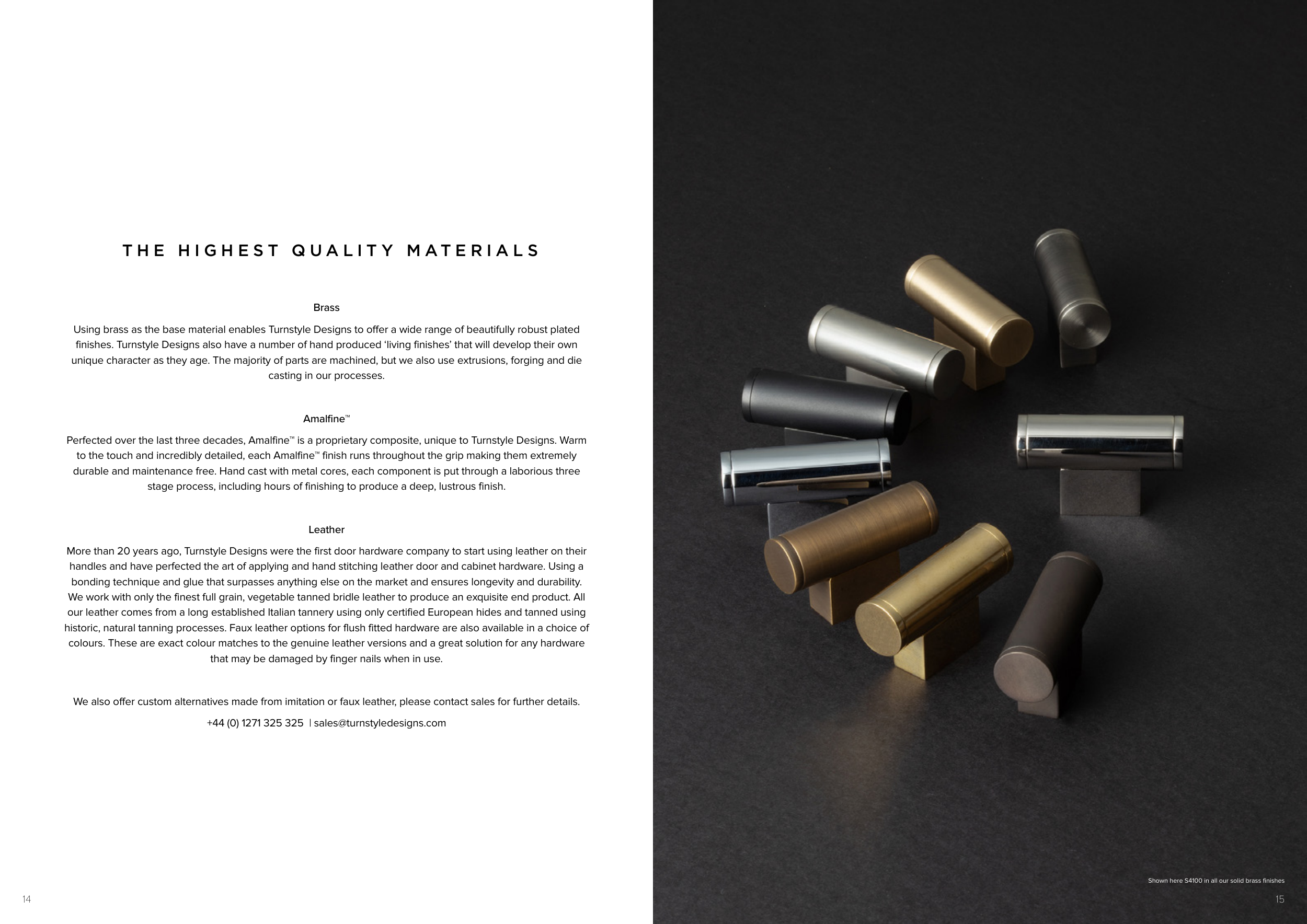

Brass

Using brass as the base material enables Turnstyle Designs to offer a wide range of beautifully robust plated

finishes. Turnstyle Designs also have a number of hand produced ‘living finishes’ that will develop their own

unique character as they age. The majority of parts are machined, but we also use extrusions, forging and die

casting in our processes.

Amalfine™

Perfected over the last three decades, Amalfine™ is a proprietary composite, unique to Turnstyle Designs. Warm

to the touch and incredibly detailed, each Amalfine™ finish runs throughout the grip making them extremely

durable and maintenance free. Hand cast with metal cores, each component is put through a laborious three

stage process, including hours of finishing to produce a deep, lustrous finish.

Leather

More than 20 years ago, Turnstyle Designs were the first door hardware company to start using leather on their

handles and have perfected the art of applying and hand stitching leather door and cabinet hardware. Using a

bonding technique and glue that surpasses anything else on the market and ensures longevity and durability.

We work with only the finest full grain, vegetable tanned bridle leather to produce an exquisite end product. All

our leather comes from a long established Italian tannery using only certified European hides and tanned using

historic, natural tanning processes. Faux leather options for flush fitted hardware are also available in a choice of

colours. These are exact colour matches to the genuine leather versions and a great solution for any hardware

that may be damaged by finger nails when in use.

We also offer custom alternatives made from imitation or faux leather, please contact sales for further details.

+44 (0) 1271 325 325 | sales@turnstyledesigns.com

T H E H I G H E S T Q U A L I T Y M A T E R I A L S

Shown here S4100 in all our solid brass finishes

15