22

23

NH3

203

192

556

564

566

117

195

199

96

504

558

147

101

513

532

141

508

98

175

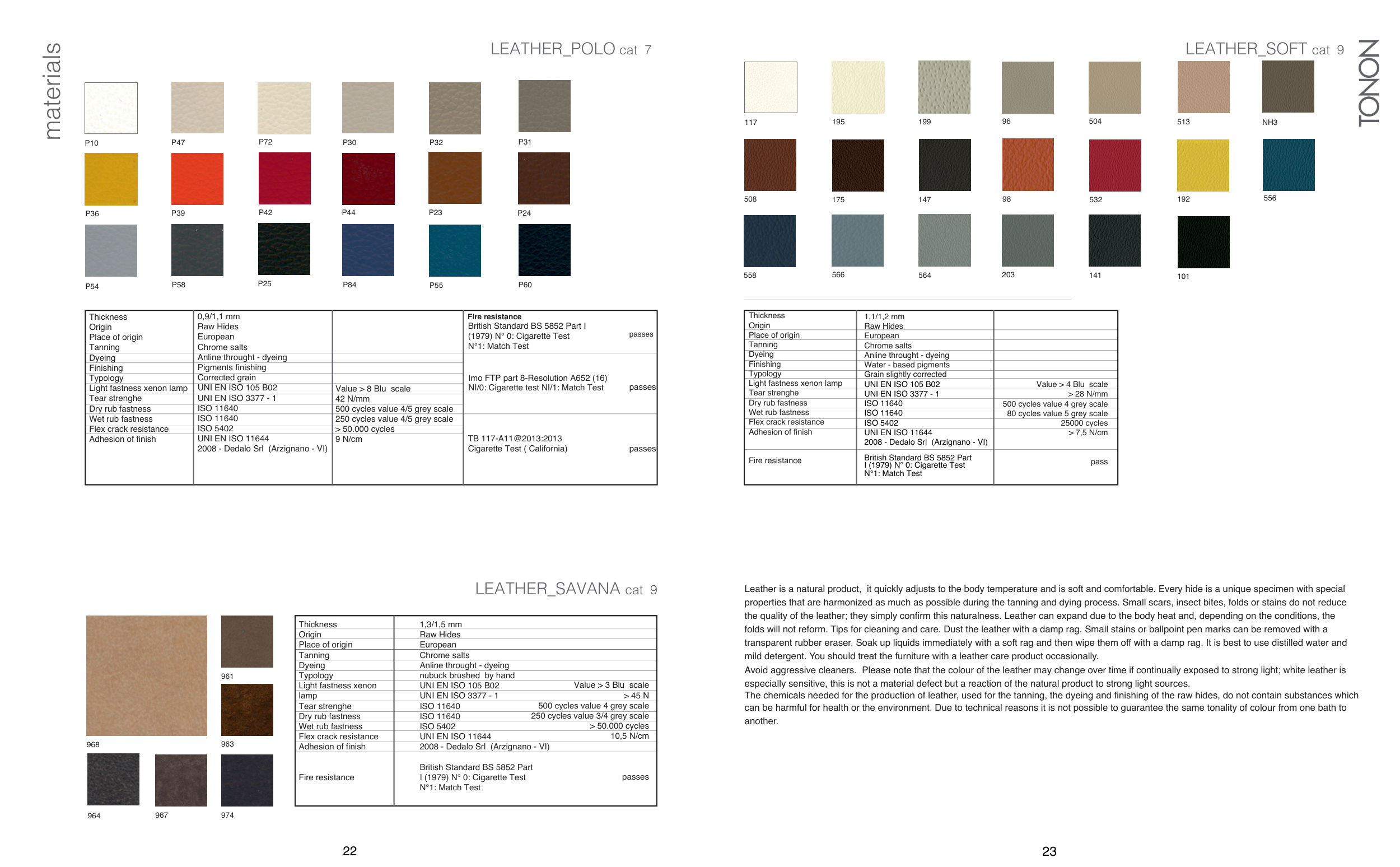

Thickness

Origin

Place of origin

Tanning

Dyeing

Finishing

Typology

Light fastness xenon lamp

Tear strenghe

Dry rub fastness

Wet rub fastness

Flex crack resistance

Adhesion of finish

Fire resistance

Value > 4 Blu scale

> 28 N/mm

500 cycles value 4 grey scale

80 cycles value 5 grey scale

25000 cycles

> 7,5 N/cm

pass

1,1/1,2 mm

Raw Hides

European

Chrome salts

Anline throught - dyeing

Water - based pigments

Grain slightly corrected

UNI EN ISO 105 B02

UNI EN ISO 3377 - 1

ISO 11640

ISO 11640

ISO 5402

UNI EN ISO 11644

2008 - Dedalo Srl (Arzignano - VI)

British Standard BS 5852 Part

I (1979) N° 0: Cigarette Test

N°1: Match Test

LEATHER_SOFT cat 9

materials

968

964

961

967

974

963

Thickness

Origin

Place of origin

Tanning

Dyeing

Typology

Light fastness xenon

lamp

Tear strenghe

Dry rub fastness

Wet rub fastness

Flex crack resistance

Adhesion of finish

Fire resistance

Value > 3 Blu scale

> 45 N

500 cycles value 4 grey scale

250 cycles value 3/4 grey scale

> 50.000 cycles

10,5 N/cm

passes

1,3/1,5 mm

Raw Hides

European

Chrome salts

Anline throught - dyeing

nubuck brushed by hand

UNI EN ISO 105 B02

UNI EN ISO 3377 - 1

ISO 11640

ISO 11640

ISO 5402

UNI EN ISO 11644

2008 - Dedalo Srl (Arzignano - VI)

British Standard BS 5852 Part

I (1979) N° 0: Cigarette Test

N°1: Match Test

LEATHER_SAVANA cat 9

LEATHER_POLO cat 7

P54

P42

P23

P32

P44

P10

P36

P72

P39

P58

P60

P30

P55

P84

P24

P25

P31

P47

Leather is a natural product, it quickly adjusts to the body temperature and is soft and comfortable. Every hide is a unique specimen with special

properties that are harmonized as much as possible during the tanning and dying process. Small scars, insect bites, folds or stains do not reduce

the quality of the leather; they simply confirm this naturalness. Leather can expand due to the body heat and, depending on the conditions, the

folds will not reform. Tips for cleaning and care. Dust the leather with a damp rag. Small stains or ballpoint pen marks can be removed with a

transparent rubber eraser. Soak up liquids immediately with a soft rag and then wipe them off with a damp rag. It is best to use distilled water and

mild detergent. You should treat the furniture with a leather care product occasionally.

Avoid aggressive cleaners. Please note that the colour of the leather may change over time if continually exposed to strong light; white leather is

especially sensitive, this is not a material defect but a reaction of the natural product to strong light sources.

The chemicals needed for the production of leather, used for the tanning, the dyeing and finishing of the raw hides, do not contain substances which

can be harmful for health or the environment. Due to technical reasons it is not possible to guarantee the same tonality of colour from one bath to

another.

Thickness

Origin

Place of origin

Tanning

Dyeing

Finishing

Typology

Light fastness xenon lamp

Tear strenghe

Dry rub fastness

Wet rub fastness

Flex crack resistance

Adhesion of finish

Fire resistance

Value > 8 Blu scale

42 N/mm

500 cycles value 4/5 grey scale

250 cycles value 4/5 grey scale

> 50.000 cycles

9 N/cm

passes

passes

passes

0,9/1,1 mm

Raw Hides

European

Chrome salts

Anline throught - dyeing

Pigments finishing

Corrected grain

UNI EN ISO 105 B02

UNI EN ISO 3377 - 1

ISO 11640

ISO 11640

ISO 5402

UNI EN ISO 11644

2008 - Dedalo Srl (Arzignano - VI)

TB 117-A11@2013:2013

Cigarette Test ( California)

Imo FTP part 8-Resolution A652 (16)

NI/0: Cigarette test NI/1: Match Test

British Standard BS 5852 Part I

(1979) N° 0: Cigarette Test

N°1: Match Test