199

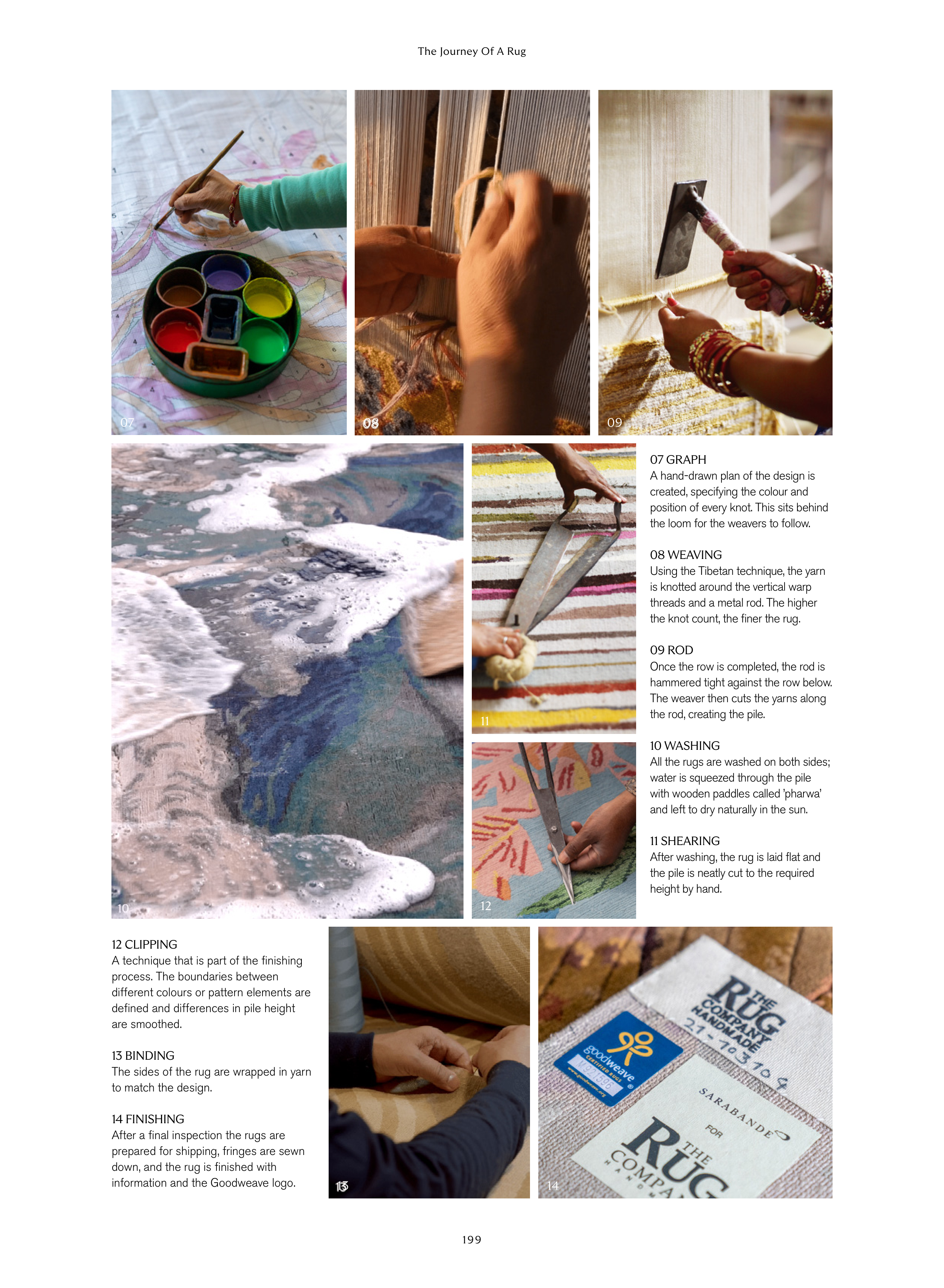

The Journey Of A Rug

07

08

09

11

12

13

14

12 CLIPPING

A technique that is part of the finishing

process. The boundaries between

different colours or pattern elements are

defined and differences in pile height

are smoothed.

13 BINDING

The sides of the rug are wrapped in yarn

to match the design.

14 FINISHING

After a final inspection the rugs are

prepared for shipping, fringes are sewn

down, and the rug is finished with

information and the Goodweave logo.

07 GRAPH

A hand-drawn plan of the design is

created, specifying the colour and

position of every knot. This sits behind

the loom for the weavers to follow.

08 WEAVING

Using the Tibetan technique, the yarn

is knotted around the vertical warp

threads and a metal rod. The higher

the knot count, the finer the rug.

09 ROD

Once the row is completed, the rod is

hammered tight against the row below.

The weaver then cuts the yarns along

the rod, creating the pile.

10 WASHING

All the rugs are washed on both sides;

water is squeezed through the pile

with wooden paddles called ’pharwa’

and left to dry naturally in the sun.

11 SHEARING

After washing, the rug is laid flat and

the pile is neatly cut to the required

height by hand.