14

Sand and minerals are our raw material, from the

fusion of these we get glass. In a dedicated factory,

stainless steel processing takes place, in which cages

that will act as a disposable mould are produced.

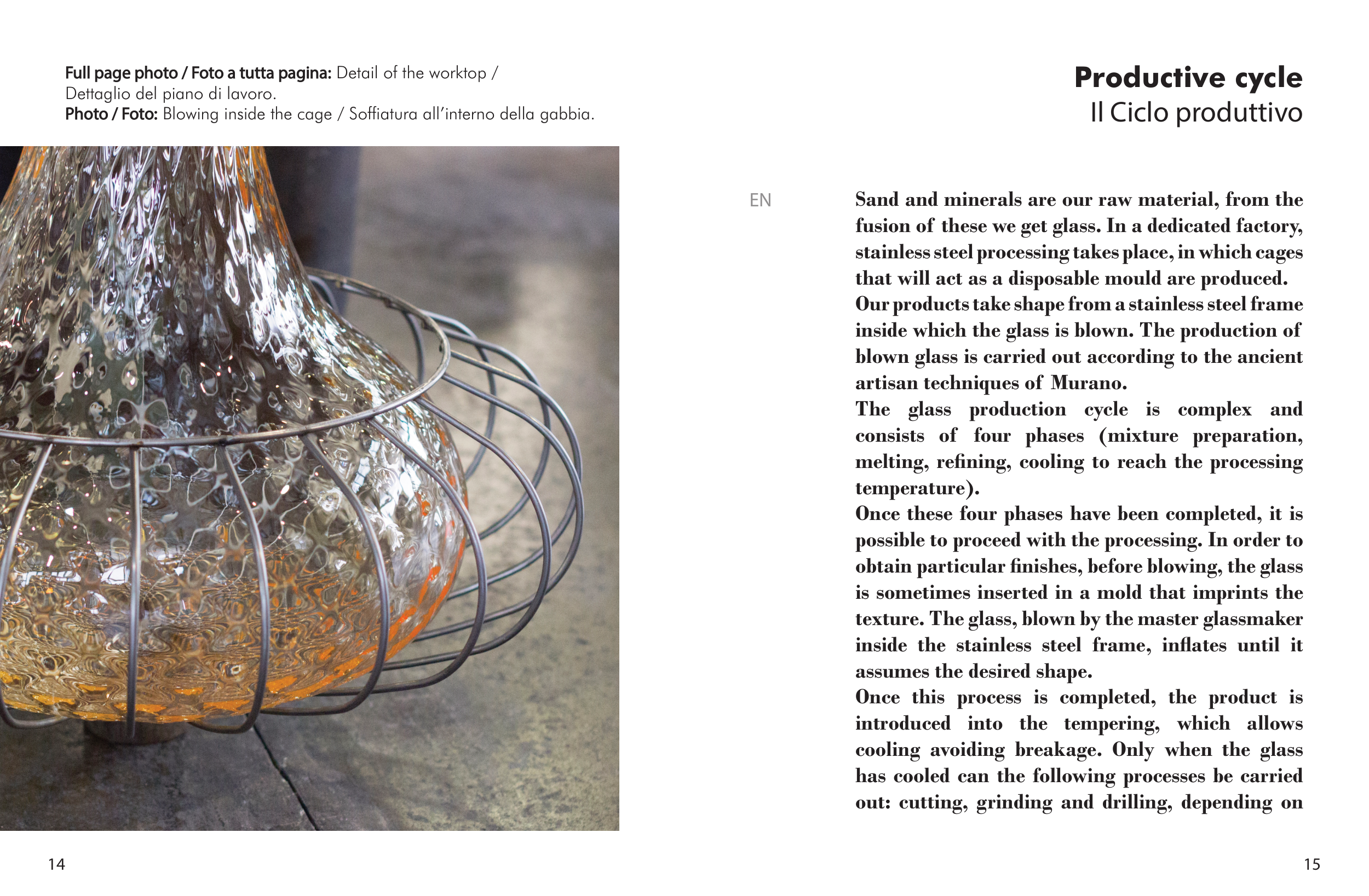

Our products take shape from a stainless steel frame

inside which the glass is blown. The production of

blown glass is carried out according to the ancient

artisan techniques of Murano.

The glass production cycle is complex and

consists of four phases (mixture preparation,

melting, refining, cooling to reach the processing

temperature).

Once these four phases have been completed, it is

possible to proceed with the processing. In order to

obtain particular finishes, before blowing, the glass

is sometimes inserted in a mold that imprints the

texture. The glass, blown by the master glassmaker

inside the stainless steel frame, inflates until it

assumes the desired shape.

Once this process is completed, the product is

introduced into the tempering, which allows

cooling avoiding breakage. Only when the glass

has cooled can the following processes be carried

out: cutting, grinding and drilling, depending on

Productive cycle

Il Ciclo produttivo

15

Full page photo /

Full page photo / Foto a tutta pagina:

Foto a tutta pagina: Detail of the worktop /

Dettaglio del piano di lavoro.

Photo / Foto:

Photo / Foto: Blowing inside the cage / Soffiatura all’interno della gabbia.

EN