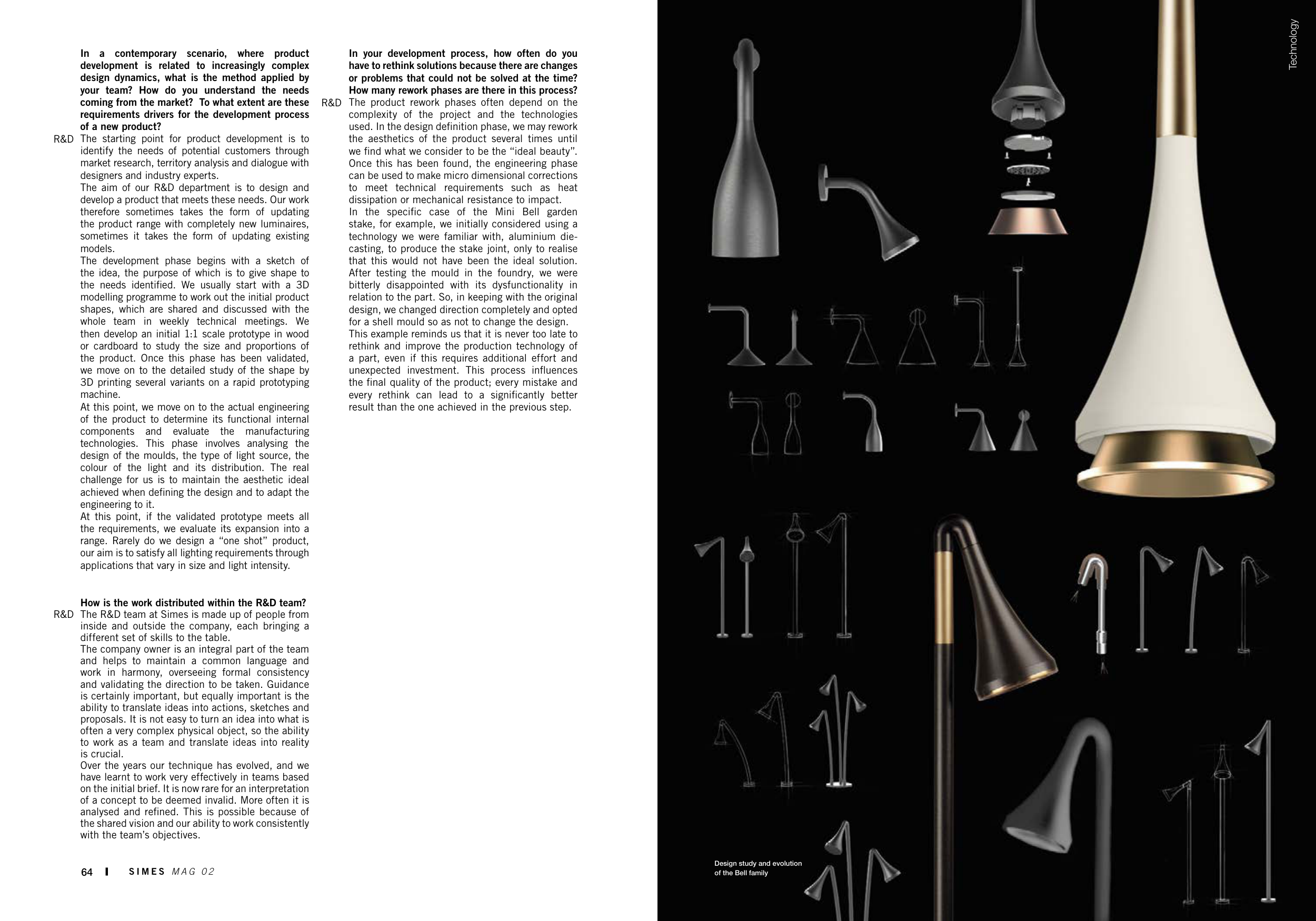

Design study and evolution

of the Bell family

In a contemporary scenario, where product

development is related to increasingly complex

design dynamics, what is the method applied by

your team? How do you understand the needs

coming from the market? To what extent are these

requirements drivers for the development process

of a new product?

The starting point for product development is to

identify the needs of potential customers through

market research, territory analysis and dialogue with

designers and industry experts.

The aim of our R&D department is to design and

develop a product that meets these needs. Our work

therefore sometimes takes the form of updating

the product range with completely new luminaires,

sometimes it takes the form of updating existing

models.

The development phase begins with a sketch of

the idea, the purpose of which is to give shape to

the needs identified. We usually start with a 3D

modelling programme to work out the initial product

shapes, which are shared and discussed with the

whole team in weekly technical meetings. We

then develop an initial 1:1 scale prototype in wood

or cardboard to study the size and proportions of

the product. Once this phase has been validated,

we move on to the detailed study of the shape by

3D printing several variants on a rapid prototyping

machine.

At this point, we move on to the actual engineering

of the product to determine its functional internal

components and evaluate the manufacturing

technologies. This phase involves analysing the

design of the moulds, the type of light source, the

colour of the light and its distribution. The real

challenge for us is to maintain the aesthetic ideal

achieved when defining the design and to adapt the

engineering to it.

At this point, if the validated prototype meets all

the requirements, we evaluate its expansion into a

range. Rarely do we design a “one shot” product,

our aim is to satisfy all lighting requirements through

applications that vary in size and light intensity.

How is the work distributed within the R&D team?

The R&D team at Simes is made up of people from

inside and outside the company, each bringing a

different set of skills to the table.

The company owner is an integral part of the team

and helps to maintain a common language and

work in harmony, overseeing formal consistency

and validating the direction to be taken. Guidance

is certainly important, but equally important is the

ability to translate ideas into actions, sketches and

proposals. It is not easy to turn an idea into what is

often a very complex physical object, so the ability

to work as a team and translate ideas into reality

is crucial.

Over the years our technique has evolved, and we

have learnt to work very effectively in teams based

on the initial brief. It is now rare for an interpretation

of a concept to be deemed invalid. More often it is

analysed and refined. This is possible because of

the shared vision and our ability to work consistently

with the team’s objectives.

In your development process, how often do you

have to rethink solutions because there are changes

or problems that could not be solved at the time?

How many rework phases are there in this process?

The product rework phases often depend on the

complexity of the project and the technologies

used. In the design definition phase, we may rework

the aesthetics of the product several times until

we find what we consider to be the “ideal beauty”.

Once this has been found, the engineering phase

can be used to make micro dimensional corrections

to meet technical requirements such as heat

dissipation or mechanical resistance to impact.

In the specific case of the Mini Bell garden

stake, for example, we initially considered using a

technology we were familiar with, aluminium die-

casting, to produce the stake joint, only to realise

that this would not have been the ideal solution.

After testing the mould in the foundry, we were

bitterly disappointed with its dysfunctionality in

relation to the part. So, in keeping with the original

design, we changed direction completely and opted

for a shell mould so as not to change the design.

This example reminds us that it is never too late to

rethink and improve the production technology of

a part, even if this requires additional effort and

unexpected investment. This process influences

the final quality of the product; every mistake and

every rethink can lead to a significantly better

result than the one achieved in the previous step.

R&D

R&D

R&D

Technology

64

S I M E S M A G 0 2