Appendix

Note tecniche ∙ Technical notes

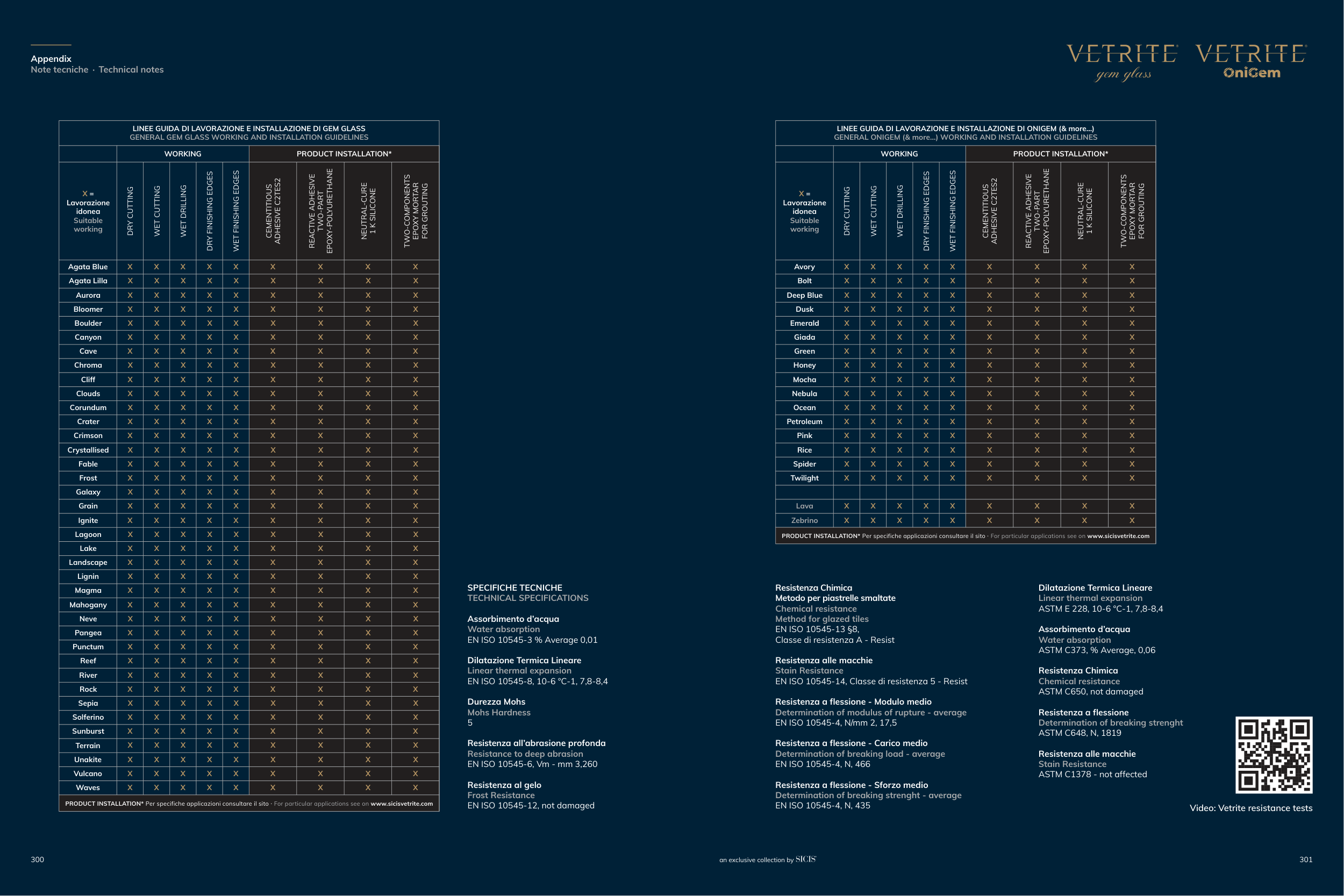

LINEE GUIDA DI LAVORAZIONE E INSTALLAZIONE DI GEM GLASS

GENERAL GEM GLASS WORKING AND INSTALLATION GUIDELINES

PRODUCT INSTALLATION* Per specifiche applicazioni consultare il sito ∙ For particular applications see on www.sicisvetrite.com

WORKING

Agata Blue

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X =

Lavorazione

idonea

Suitable

working

Agata Lilla

Aurora

Bloomer

Boulder

Canyon

Cave

Chroma

Cliff

Clouds

Corundum

Crater

Crimson

Crystallised

Fable

Frost

Galaxy

Grain

Ignite

Lagoon

Lake

Landscape

Lignin

Magma

Mahogany

Neve

Pangea

Punctum

Reef

River

Rock

Sepia

Solferino

Sunburst

Terrain

Unakite

Vulcano

Waves

DRY FINISHING EDGES

WET FINISHING EDGES

CEMENTITIOUS

ADHESIVE C2TES2

REACTIVE ADHESIVE

TWO-PART

EPOXY-POLYURETHANE

NEUTRAL-CURE

1 K SILICONE

TWO-COMPONENTS

EPOXY MORTAR

FOR GROUTING

WET DRILLING

WET CUTTING

DRY CUTTING

PRODUCT INSTALLATION*

LINEE GUIDA DI LAVORAZIONE E INSTALLAZIONE DI ONIGEM (& more...)

GENERAL ONIGEM (& more...) WORKING AND INSTALLATION GUIDELINES

PRODUCT INSTALLATION* Per specifiche applicazioni consultare il sito ∙ For particular applications see on www.sicisvetrite.com

WORKING

Avory

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X =

Lavorazione

idonea

Suitable

working

Bolt

Deep Blue

Dusk

Emerald

Giada

Green

Honey

Mocha

Nebula

Ocean

Petroleum

Pink

Rice

Spider

Twilight

Lava

Zebrino

DRY FINISHING EDGES

WET FINISHING EDGES

CEMENTITIOUS

ADHESIVE C2TES2

REACTIVE ADHESIVE

TWO-PART

EPOXY-POLYURETHANE

NEUTRAL-CURE

1 K SILICONE

TWO-COMPONENTS

EPOXY MORTAR

FOR GROUTING

WET DRILLING

WET CUTTING

DRY CUTTING

PRODUCT INSTALLATION*

SPECIFICHE TECNICHE

TECHNICAL SPECIFICATIONS

Assorbimento d’acqua

Water absorption

EN ISO 10545-3 % Average 0,01

Dilatazione Termica Lineare

Linear thermal expansion

EN ISO 10545-8, 10-6 °C-1, 7,8-8,4

Durezza Mohs

Mohs Hardness

5

Resistenza all’abrasione profonda

Resistance to deep abrasion

EN ISO 10545-6, Vm - mm 3,260

Resistenza al gelo

Frost Resistance

EN ISO 10545-12, not damaged

Resistenza Chimica

Metodo per piastrelle smaltate

Chemical resistance

Method for glazed tiles

EN ISO 10545-13 §8,

Classe di resistenza A - Resist

Resistenza alle macchie

Stain Resistance

EN ISO 10545-14, Classe di resistenza 5 - Resist

Resistenza a flessione - Modulo medio

Determination of modulus of rupture - average

EN ISO 10545-4, N/mm 2, 17,5

Resistenza a flessione - Carico medio

Determination of breaking load - average

EN ISO 10545-4, N, 466

Resistenza a flessione - Sforzo medio

Determination of breaking strenght - average

EN ISO 10545-4, N, 435

Dilatazione Termica Lineare

Linear thermal expansion

ASTM E 228, 10-6 °C-1, 7,8-8,4

Assorbimento d’acqua

Water absorption

ASTM C373, % Average, 0,06

Resistenza Chimica

Chemical resistance

ASTM C650, not damaged

Resistenza a flessione

Determination of breaking strenght

ASTM C648, N, 1819

Resistenza alle macchie

Stain Resistance

ASTM C1378 - not affected

Video: Vetrite resistance tests

an exclusive collection by

300

301