8

9

Oikos’ strength

Arckey

Cylinder

cylinder with

service

Arckey

Cylinder

cylinder with

service

Specifications

Safety door TEKNO, FLUSH WITH INTERNAL WALL / COPLANAR WITH SURROUNDING

FRAME: leaf in 15/10 electro-galvanized sheet steel with 3 horizontal reinforcing bars and 2

vertical omegas, 30/10 lock protection plate, closing profiles and frame covering profiles in

aluminum in 5 finishes, perimeter frame sealing strip, internal insulation, draught excluder,

brushed chrome square internal/external kit, closed sector frame, 2 patented concealed

hinges, 2 side switchlocks, cylinder lock with defender included.

Specifications

Safety door PROJECT INTERIOR COPLANAR: leaf in 15/10 electro-galvanized sheet steel

with 3 horizontal reinforcing bars and 2 vertical omegas, 30/10 lock protection plate, closing

profiles and frame covering profiles in aluminum in three finishes, perimeter frame sealing

strip, internal insulation, draught excluder, internal handle, external fixed knob and wide

angle brass spy hole, closed sector frame, 2 patented concealed hinges, 2 side switchlocks,

cylinder lock with defender included.

1

1

11

11

14

14

12

12

9

9

8

8

7

7

2

2

3

3

4

4

17

17

6

6

5

5

16

16

13

13

10

10

15

15

1

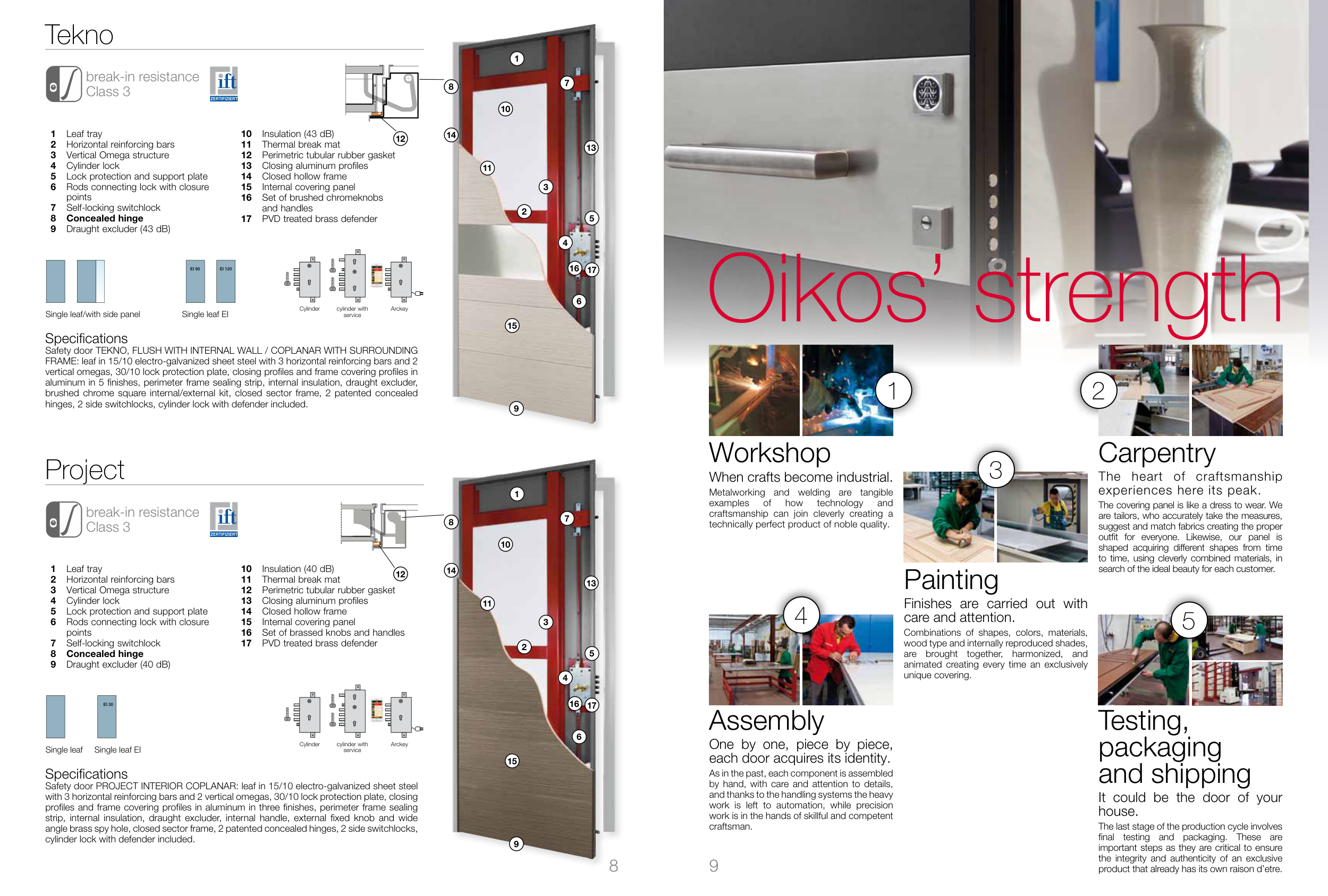

Leaf tray

2

Horizontal reinforcing bars

3

Vertical Omega structure

4

Cylinder lock

5

Lock protection and support plate

6

Rods connecting lock with closure

points

7

Self-locking switchlock

8

Concealed hinge

9

Draught excluder (43 dB)

10

Insulation (43 dB)

11

Thermal break mat

12

Perimetric tubular rubber gasket

13

Closing aluminum profiles

14

Closed hollow frame

15

Internal covering panel

16

Set of brushed chromeknobs

and handles

17

PVD treated brass defender

1

Leaf tray

2

Horizontal reinforcing bars

3

Vertical Omega structure

4

Cylinder lock

5

Lock protection and support plate

6

Rods connecting lock with closure

points

7

Self-locking switchlock

8

Concealed hinge

9

Draught excluder (40 dB)

10

Insulation (40 dB)

11

Thermal break mat

12

Perimetric tubular rubber gasket

13

Closing aluminum profiles

14

Closed hollow frame

15

Internal covering panel

16

Set of brassed knobs and handles

17

PVD treated brass defender

break-in resistance

Class 3

Tekno

Project

Single leaf/with side panel

EI 30

EI 60

EI 90

EI 120

EI 30

EI 60

EI 90

EI 120

Single leaf

EI 30

EI 60

EI 90

EI 120

Single leaf EI

Single leaf EI

EI 30

EI 60

EI 90

EI 120

EI 30

EI 60

EI 90

EI 120

Testing,

packaging

and shipping

It could be the door of your

house.

The last stage of the production cycle involves

final testing and packaging. These are

important steps as they are critical to ensure

the integrity and authenticity of an exclusive

product that already has its own raison d’etre.

Assembly

One by one, piece by piece,

each door acquires its identity.

As in the past, each component is assembled

by hand, with care and attention to details,

and thanks to the handling systems the heavy

work is left to automation, while precision

work is in the hands of skillful and competent

craftsman.

Painting

Finishes are carried out with

care and attention.

Combinations of shapes, colors, materials,

wood type and internally reproduced shades,

are brought together, harmonized, and

animated creating every time an exclusively

unique covering.

Carpentry

The heart of craftsmanship

experiences here its peak.

The covering panel is like a dress to wear. We

are tailors, who accurately take the measures,

suggest and match fabrics creating the proper

outfit for everyone. Likewise, our panel is

shaped acquiring different shapes from time

to time, using cleverly combined materials, in

search of the ideal beauty for each customer.

Workshop

When crafts become industrial.

Metalworking and welding are tangible

examples

of

how

technology

and

craftsmanship can join cleverly creating a

technically perfect product of noble quality.

1

2

3

4

5

break-in resistance

Class 3