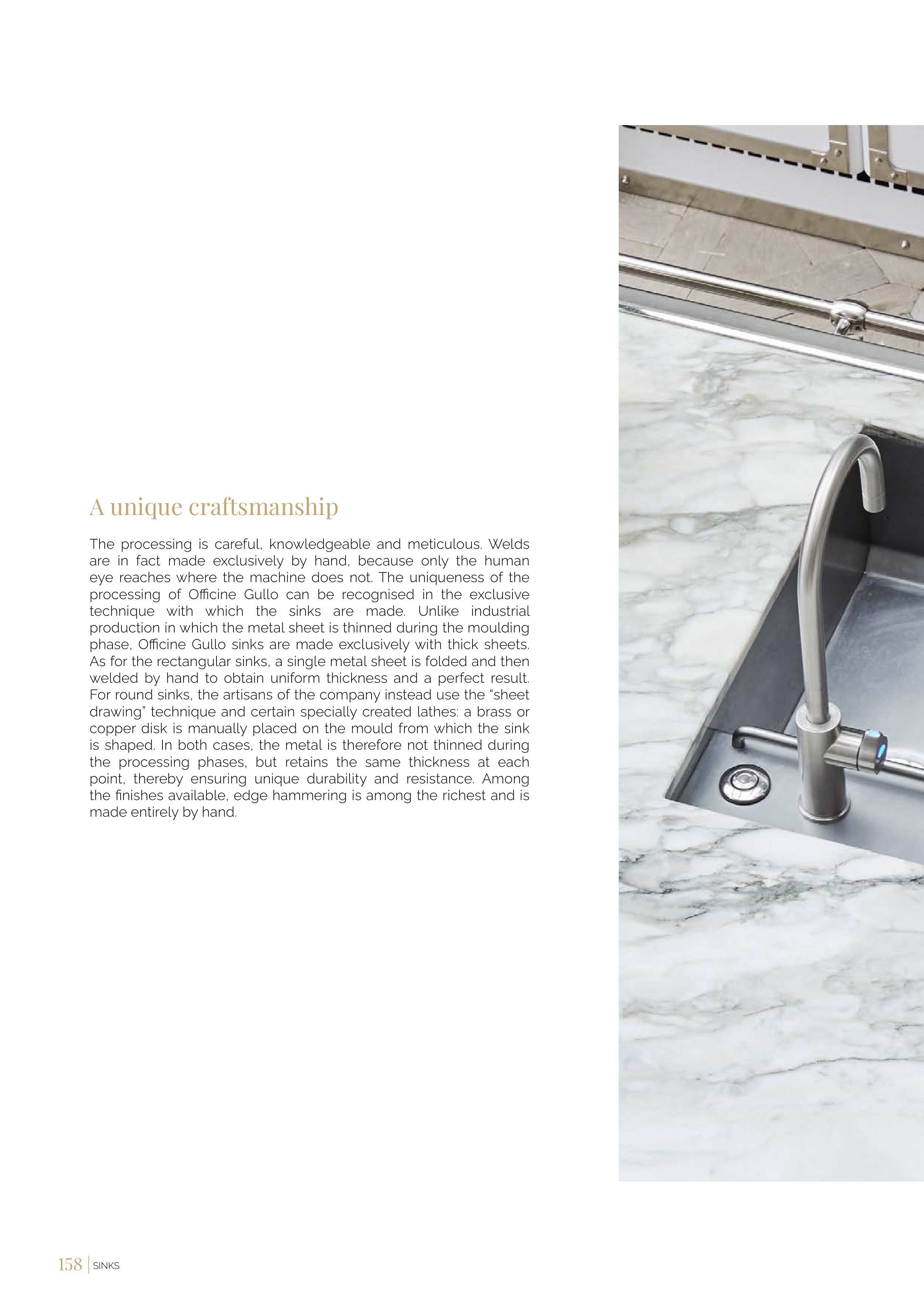

A unique craftsmanship

The processing is careful, knowledgeable and meticulous. Welds

are in fact made exclusively by hand, because only the human

eye reaches where the machine does not. The uniqueness of the

processing of Officine Gullo can be recognised in the exclusive

technique with which the sinks are made. Unlike industrial

production in which the metal sheet is thinned during the moulding

phase, Officine Gullo sinks are made exclusively with thick sheets.

As for the rectangular sinks, a single metal sheet is folded and then

welded by hand to obtain uniform thickness and a perfect result.

For round sinks, the artisans of the company instead use the “sheet

drawing” technique and certain specially created lathes: a brass or

copper disk is manually placed on the mould from which the sink

is shaped. In both cases, the metal is therefore not thinned during

the processing phases, but retains the same thickness at each

point, thereby ensuring unique durability and resistance. Among

the finishes available, edge hammering is among the richest and is

made entirely by hand.

158 | SINKS