14

15

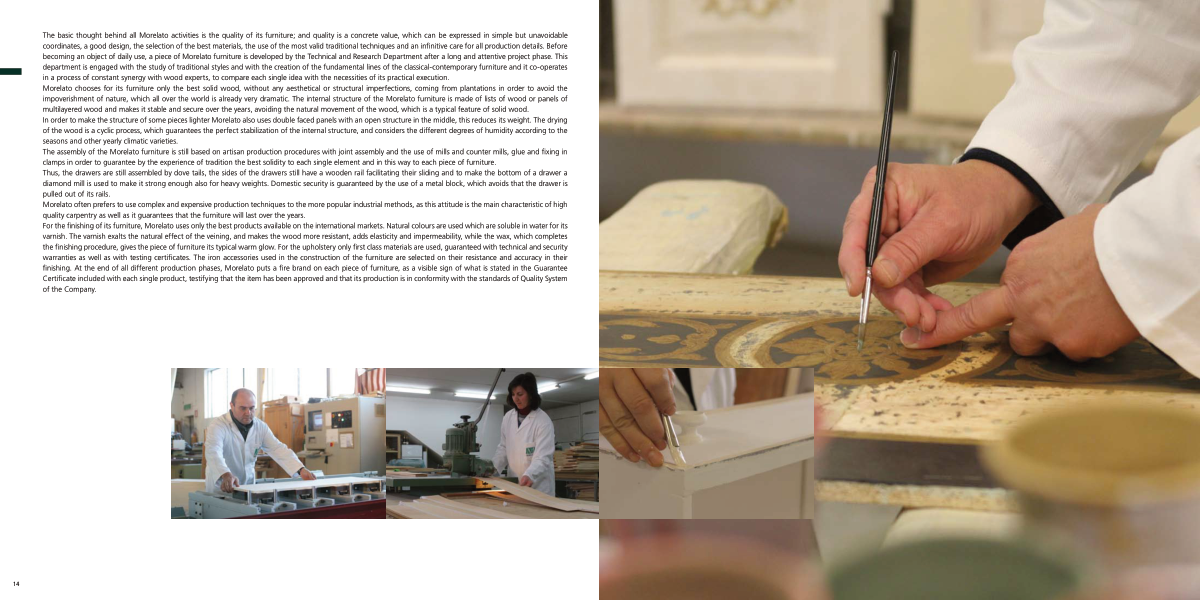

The basic thought behind all Morelato activities is the quality of its furniture; and quality is a concrete value, which can be expressed in simple but unavoidable

coordinates, a good design, the selection of the best materials, the use of the most valid traditional techniques and an infinitive care for all production details. Before

becoming an object of daily use, a piece of Morelato furniture is developed by the Technical and Research Department after a long and attentive project phase. This

department is engaged with the study of traditional styles and with the creation of the fundamental lines of the classical-contemporary furniture and it co-operates

in a process of constant synergy with wood experts, to compare each single idea with the necessities of its practical execution.

Morelato chooses for its furniture only the best solid wood, without any aesthetical or structural imperfections, coming from plantations in order to avoid the

impoverishment of nature, which all over the world is already very dramatic. The internal structure of the Morelato furniture is made of lists of wood or panels of

multilayered wood and makes it stable and secure over the years, avoiding the natural movement of the wood, which is a typical feature of solid wood.

In order to make the structure of some pieces lighter Morelato also uses double faced panels with an open structure in the middle, this reduces its weight. The drying

of the wood is a cyclic process, which guarantees the perfect stabilization of the internal structure, and considers the different degrees of humidity according to the

seasons and other yearly climatic varieties.

The assembly of the Morelato furniture is still based on artisan production procedures with joint assembly and the use of mills and counter mills, glue and fixing in

clamps in order to guarantee by the experience of tradition the best solidity to each single element and in this way to each piece of furniture.

Thus, the drawers are still assembled by dove tails, the sides of the drawers still have a wooden rail facilitating their sliding and to make the bottom of a drawer a

diamond mill is used to make it strong enough also for heavy weights. Domestic security is guaranteed by the use of a metal block, which avoids that the drawer is

pulled out of its rails.

Morelato often prefers to use complex and expensive production techniques to the more popular industrial methods, as this attitude is the main characteristic of high

quality carpentry as well as it guarantees that the furniture will last over the years.

For the finishing of its furniture, Morelato uses only the best products available on the international markets. Natural colours are used which are soluble in water for its

varnish. The varnish exalts the natural effect of the veining, and makes the wood more resistant, adds elasticity and impermeability, while the wax, which completes

the finishing procedure, gives the piece of furniture its typical warm glow. For the upholstery only first class materials are used, guaranteed with technical and security

warranties as well as with testing certificates. The iron accessories used in the construction of the furniture are selected on their resistance and accuracy in their

finishing. At the end of all different production phases, Morelato puts a fire brand on each piece of furniture, as a visible sign of what is stated in the Guarantee

Certificate included with each single product, testifying that the item has been approved and that its production is in conformity with the standards of Quality System

of the Company.