STORIE DI MATERIA

GENERAL INFORMATION

Marble slabs are made of natural rock materials of sedimentary origin composed mainly of calcium

carbonate (CaCo3). Therefore the marble slabs may vary in appearance one with the others, presenting

small imperfections, veins, small holes, surface inequalities, differences in veins or shades.

The colour depends on the presence of mineral impurities (clay, sand, iron oxides, lime, flint

nodules) existing in granules or in layers within the original sedimentary rock or from the process of

metamorphosis of limestone free from impurities. As a natural material, it should be noted that

imperfections must therefore be considered not as defects but as structural characteristics of the

product itself, which make it unique and inimitable. The finish provides a sanding and polishing

process obtained by using the latest generation of diamond abrasives which gives the surface gre-

ater shine and durability and the matt or glossy appearance according to the choice. To obtain the

matt effect, 5 abrasive steps are required, for the glossy effect 8 steps are required. Every single

part of which the marble is composed, assimilates, in a different way, the working with the abrasi-

ves. Therefore the treated surfaces can present parts more or less polished, or parts more or less

matt. The marble, after being extracted from the quarry, must be treated with particular processes

to make it homogeneous, compact and solid.

FIRST PHASE:

- vacuum-packed

- transparent resin casting in the cracks

- pressing and cladding with multilayer wooden panels

SECOND PHASE:

- the marble stone is cut in slabs with diamond blades

- resin coating and screening with a glass fiber mesh on the side of the slab which is not visible and can not

be removed

- polishing / sanding (matt) on the side of the slab’s visible part

THIRD PHASE:

- the slabs are brought to the laboratory and are processed with CNC machines

- lastly there is always the hand of the craftsman for small finishes and the application of water-repellent

stain-resistant product

Marble has poor resistance to limestone and acidic substances which, even in small quantities, can affect their

surfaces and penetrate into the pores of the material, forming non-eliminable stains.

There are no products that can protect the natural surfaces, however a surface finishing treatment is available

(on request and with surcharge) by applying a polyester lacquer (glossy or matt) which however slightly changes

the natural appearance of the product.

MAINTENANCE:

For a correct maintenance and a long life of marble, we suggest to proceed to the immediate removal of liquids

and stains, simply using a damp and soft cloth.

For ordinary maintenance, it is enough to clean the surfaces with water and neutral products: do not use

absolutely solvents, abrasive materials or aggressive liquids.

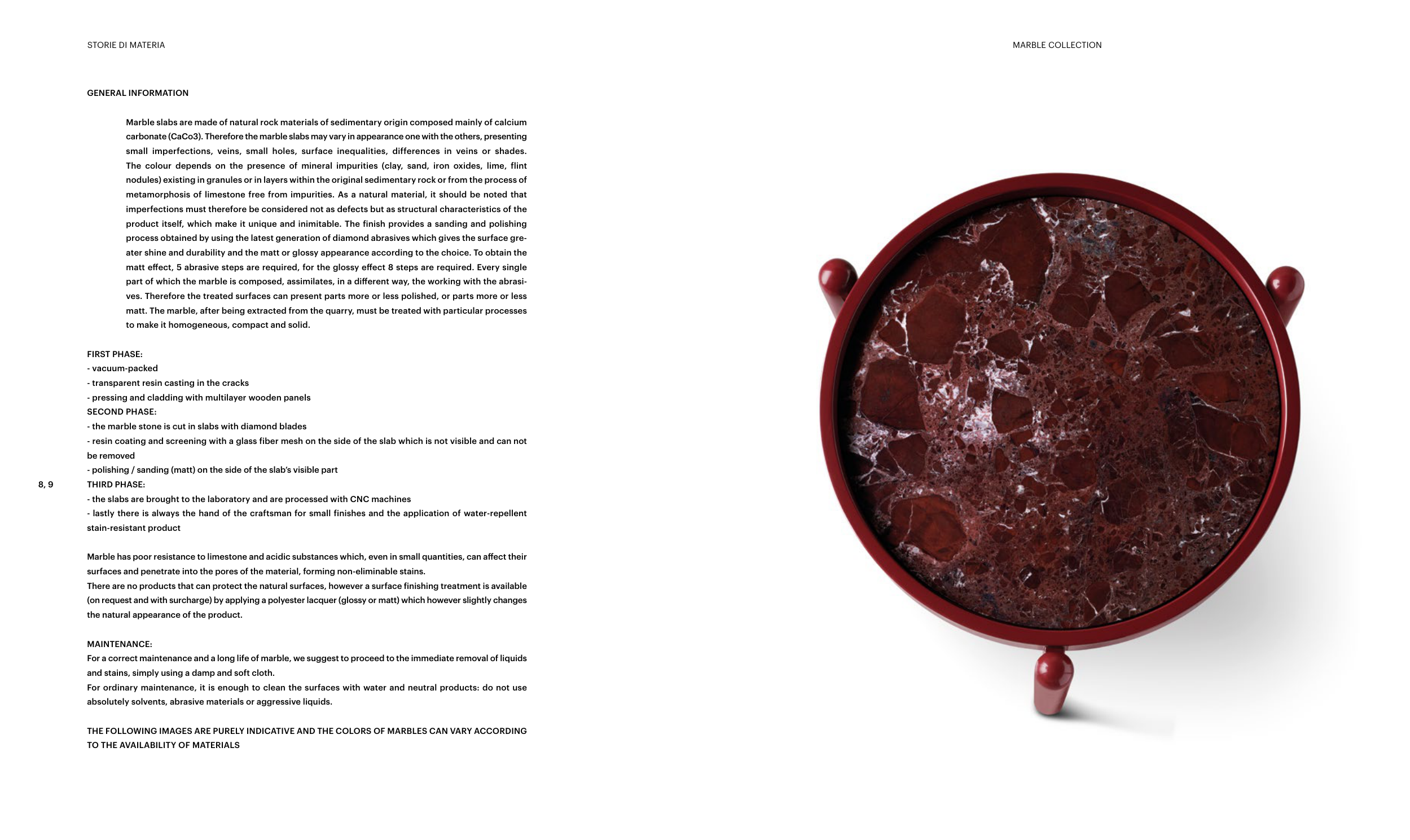

THE FOLLOWING IMAGES ARE PURELY INDICATIVE AND THE COLORS OF MARBLES CAN VARY ACCORDING

TO THE AVAILABILITY OF MATERIALS

MARBLE COLLECTION

8, 9