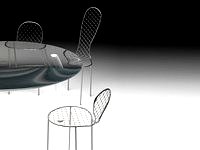

Top created from a large sheet of cast GS Plexiglas® (2000x3000mm, and 70mm thick) using a 5-axis numerical control machine. The process takes over 30 hours, andinvolves two rough-hewing and three finishing operations,followed by a further two smoothing procedures and then three polishing procedures (using abrasive paste, polishingwax and finishing polish), performed by hand, and requiring another 20 hours’ work. The holes for the insertion of the legs into the table top are made in the CNC machine by interpolation.The legs are made using 3 cast GS Plexiglas® cylinders, machine-processed to shape the part that slots into the table top, after which they are smoothed andpolished by hand. The three resulting legs are all different due to angles at which they are inserted and positioned. Drop Table is produced in a limited and numbered edition,signed by the Artist.

Italy

Italy