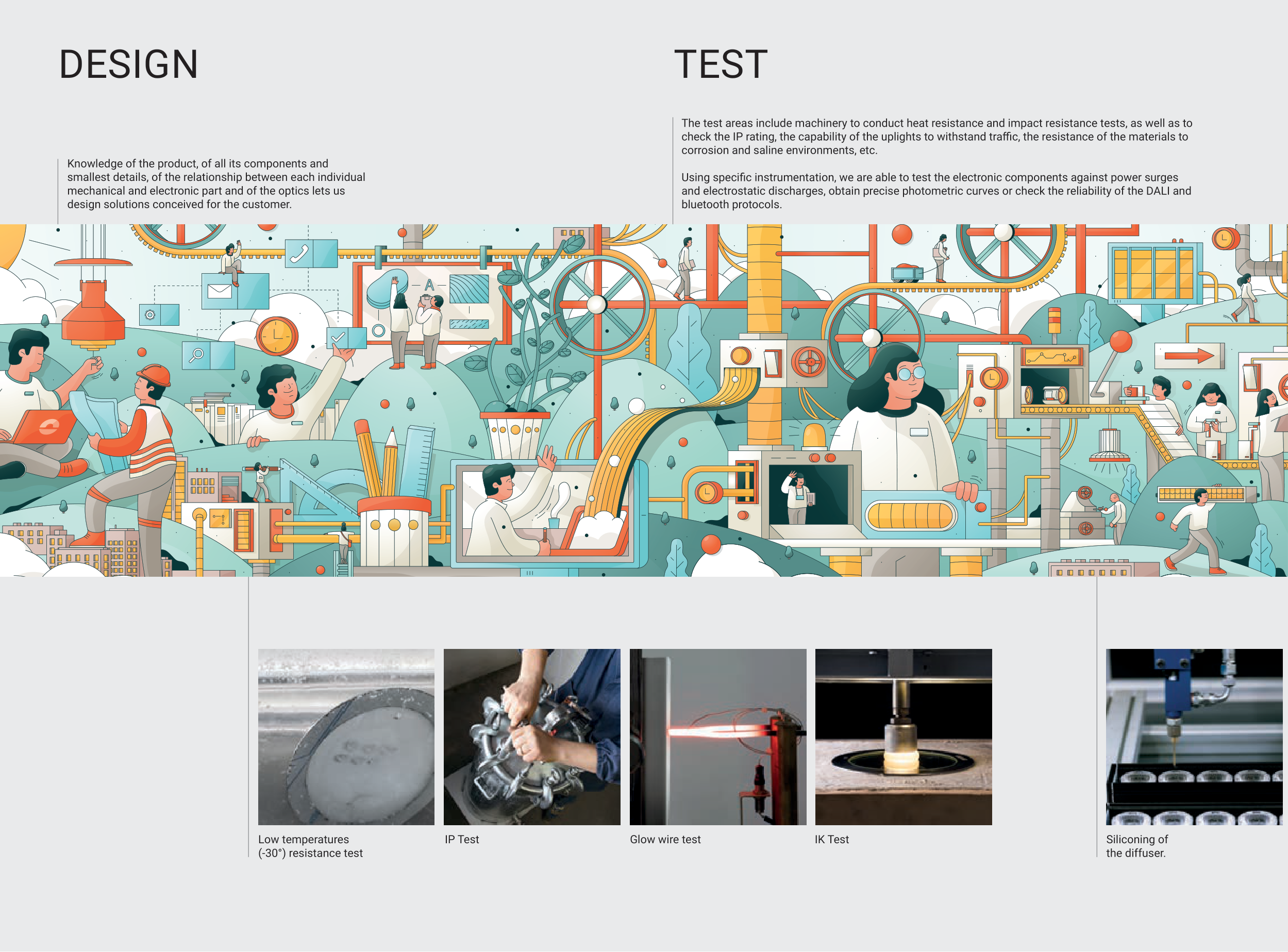

Knowledge of the product, of all its components and

smallest details, of the relationship between each individual

mechanical and electronic part and of the optics lets us

design solutions conceived for the customer.

DESIGN

TEST

Low temperatures

(-30°) resistance test

Glow wire test

IK Test

IP Test

Siliconing of

the diffuser.

The test areas include machinery to conduct heat resistance and impact resistance tests, as well as to

check the IP rating, the capability of the uplights to withstand traffic, the resistance of the materials to

corrosion and saline environments, etc.

Using specific instrumentation, we are able to test the electronic components against power surges

and electrostatic discharges, obtain precise photometric curves or check the reliability of the DALI and

bluetooth protocols.