254

Poles

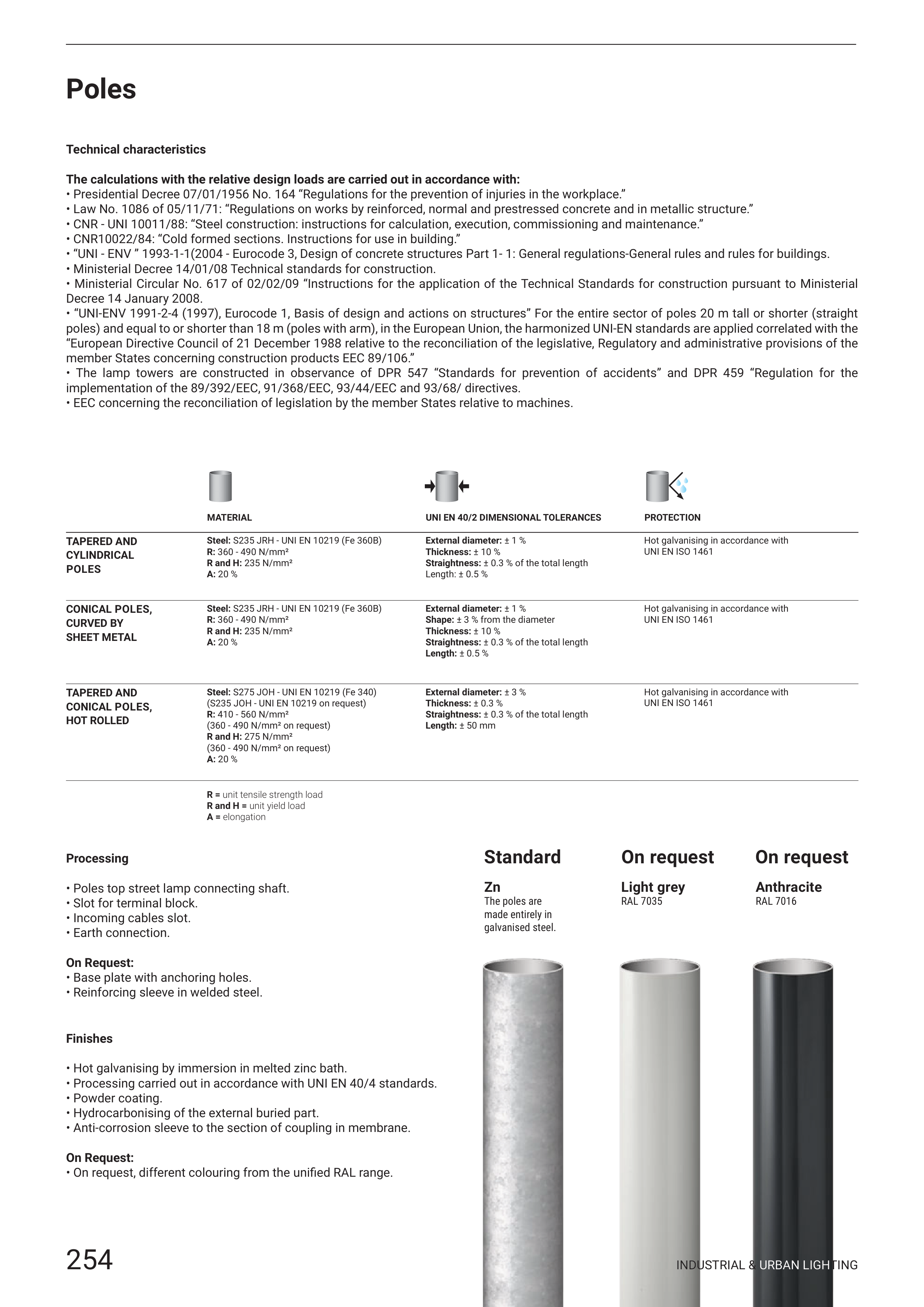

Standard

On request

On request

INDUSTRIAL & URBAN LIGHTING

Technical characteristics

The calculations with the relative design loads are carried out in accordance with:

• Presidential Decree 07/01/1956 No. 164 “Regulations for the prevention of injuries in the workplace.”

• Law No. 1086 of 05/11/71: “Regulations on works by reinforced, normal and prestressed concrete and in metallic structure.”

• CNR - UNI 10011/88: “Steel construction: instructions for calculation, execution, commissioning and maintenance.”

• CNR10022/84: “Cold formed sections. Instructions for use in building.”

• “UNI - ENV ” 1993-1-1(2004 - Eurocode 3, Design of concrete structures Part 1- 1: General regulations-General rules and rules for buildings.

• Ministerial Decree 14/01/08 Technical standards for construction.

• Ministerial Circular No. 617 of 02/02/09 “Instructions for the application of the Technical Standards for construction pursuant to Ministerial

Decree 14 January 2008.

• “UNI-ENV 1991-2-4 (1997), Eurocode 1, Basis of design and actions on structures” For the entire sector of poles 20 m tall or shorter (straight

poles) and equal to or shorter than 18 m (poles with arm), in the European Union, the harmonized UNI-EN standards are applied correlated with the

“European Directive Council of 21 December 1988 relative to the reconciliation of the legislative, Regulatory and administrative provisions of the

member States concerning construction products EEC 89/106.”

• The lamp towers are constructed in observance of DPR 547 “Standards for prevention of accidents” and DPR 459 “Regulation for the

implementation of the 89/392/EEC, 91/368/EEC, 93/44/EEC and 93/68/ directives.

• EEC concerning the reconciliation of legislation by the member States relative to machines.

Finishes

• Hot galvanising by immersion in melted zinc bath.

• Processing carried out in accordance with UNI EN 40/4 standards.

• Powder coating.

• Hydrocarbonising of the external buried part.

• Anti-corrosion sleeve to the section of coupling in membrane.

On Request:

• On request, different colouring from the unified RAL range.

Processing

• Poles top street lamp connecting shaft.

• Slot for terminal block.

• Incoming cables slot.

• Earth connection.

On Request:

• Base plate with anchoring holes.

• Reinforcing sleeve in welded steel.

MATERIAL

UNI EN 40/2 DIMENSIONAL TOLERANCES

PROTECTION

TAPERED AND

CYLINDRICAL

POLES

Steel: S235 JRH - UNI EN 10219 (Fe 360B)

R: 360 - 490 N/mm²

R and H: 235 N/mm²

A: 20 %

External diameter: ± 1 %

Thickness: ± 10 %

Straightness: ± 0.3 % of the total length

Length: ± 0.5 %

Hot galvanising in accordance with

UNI EN ISO 1461

CONICAL POLES,

CURVED BY

SHEET METAL

Steel: S235 JRH - UNI EN 10219 (Fe 360B)

R: 360 - 490 N/mm²

R and H: 235 N/mm²

A: 20 %

External diameter: ± 1 %

Shape: ± 3 % from the diameter

Thickness: ± 10 %

Straightness: ± 0.3 % of the total length

Length: ± 0.5 %

Hot galvanising in accordance with

UNI EN ISO 1461

TAPERED AND

CONICAL POLES,

HOT ROLLED

Steel: S275 JOH - UNI EN 10219 (Fe 340)

(S235 JOH - UNI EN 10219 on request)

R: 410 - 560 N/mm²

(360 - 490 N/mm² on request)

R and H: 275 N/mm²

(360 - 490 N/mm² on request)

A: 20 %

External diameter: ± 3 %

Thickness: ± 0.3 %

Straightness: ± 0.3 % of the total length

Length: ± 50 mm

Hot galvanising in accordance with

UNI EN ISO 1461

R = unit tensile strength load

R and H = unit yield load

A = elongation

Zn

The poles are

made entirely in

galvanised steel.

Light grey

RAL 7035

Anthracite

RAL 7016