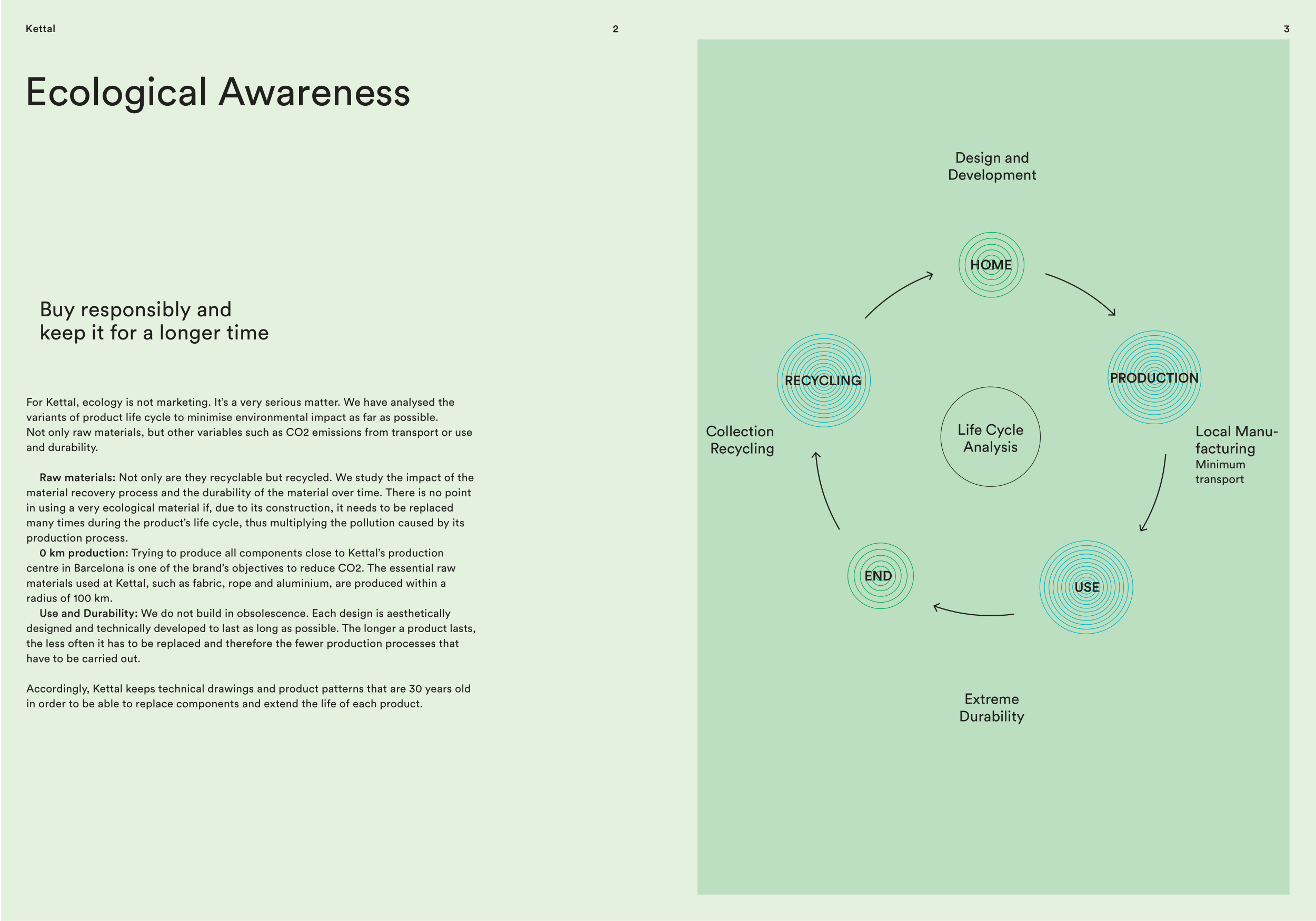

For Kettal, ecology is not marketing. It’s a very serious matter. We have analysed the

variants of product life cycle to minimise environmental impact as far as possible.

Not only raw materials, but other variables such as CO2 emissions from transport or use

and durability.

Raw materials: Not only are they recyclable but recycled. We study the impact of the

material recovery process and the durability of the material over time. There is no point

in using a very ecological material if, due to its construction, it needs to be replaced

many times during the product’s life cycle, thus multiplying the pollution caused by its

production process.

0 km production: Trying to produce all components close to Kettal’s production

centre in Barcelona is one of the brand’s objectives to reduce CO2. The essential raw

materials used at Kettal, such as fabric, rope and aluminium, are produced within a

radius of 100 km.

Use and Durability: We do not build in obsolescence. Each design is aesthetically

designed and technically developed to last as long as possible. The longer a product lasts,

the less often it has to be replaced and therefore the fewer production processes that

have to be carried out.

Accordingly, Kettal keeps technical drawings and product patterns that are 30 years old

in order to be able to replace components and extend the life of each product.

Buy responsibly and

keep it for a longer time

Design and

Development

Extreme

Durability

Collection

Recycling

Local Manu-

facturing

Minimum

transport

Life Cycle

Analysis

USE

RECYCLING

HOME

PRODUCTION

END

Kettal

Ecological Awareness

2

3