Brass Surface Treatments and Their Types

Brass is an aesthetically pleasing, durable, and versatile alloy often used in

interior design, furniture, lighting fixtures, and artistic creations. However, brass is

prone to oxidation and discoloration, so various surface treatments are applied to

preserve its beauty and increase its longevity.

1. Mechanical Surface Treatments

These methods involve processing, polishing, or texturing the brass surface.

Brushing and Sanding: Brushed or sanded brass creates a finely textured,

matte surface, often used in modern and industrial designs.

Polishing: To achieve a high-gloss finish, brass is treated with abrasive materials

of different grit sizes and finally polished with a fine paste.

Sandblasting: This technique creates a uniform, slightly rough or matte finish,

ideal for antique or rustic aesthetics.

2. Chemical Surface Treatments

Chemical treatments aim to protect the surface or create specific effects.

Patination: Various chemicals can be used to artificially accelerate the aging

process, achieving antique or vintage effects (e.g., green, blue, or brown patina).

Acid Treatment: Helps create a uniform oxidation effect, resulting in unique

shades and tones.

Lacquering or Wax Coating: A clear protective coating can be applied to patinated

or polished surfaces to prevent further oxidation.

3. Galvanic and Other Coatings

These methods involve applying different metal layers or coatings to the brass

surface.

Nickel or Chrome Plating: Provides a durable, wear-resistant, and shiny finish,

often used in bathroom and kitchen fixtures.

Gilding: Adds a luxurious appearance while protecting the brass base from

oxidation.

Powder Coating: Powder-coated brass surfaces are more durable and resistant

to environmental factors.

4. Oil-Based Protection

Raw or polished brass can be regularly treated with special oils (such as linseed

oil or microcrystalline wax) to slow down oxidation and maintain its original shine.

Conclusion

The choice of surface treatment depends on the intended use and aesthe-

tic expectations. Polishing and lacquering are ideal for modern, glossy surfaces,

while patination or brushing creates an antique effect. Galvanic coatings and

powder coating offer longer-lasting protection, while oils and waxes provide a

natural solution against oxidation.

For unique or long-lasting surface treatments, consulting a specialist ensures the

most suitable technology is applied for the desired effect.

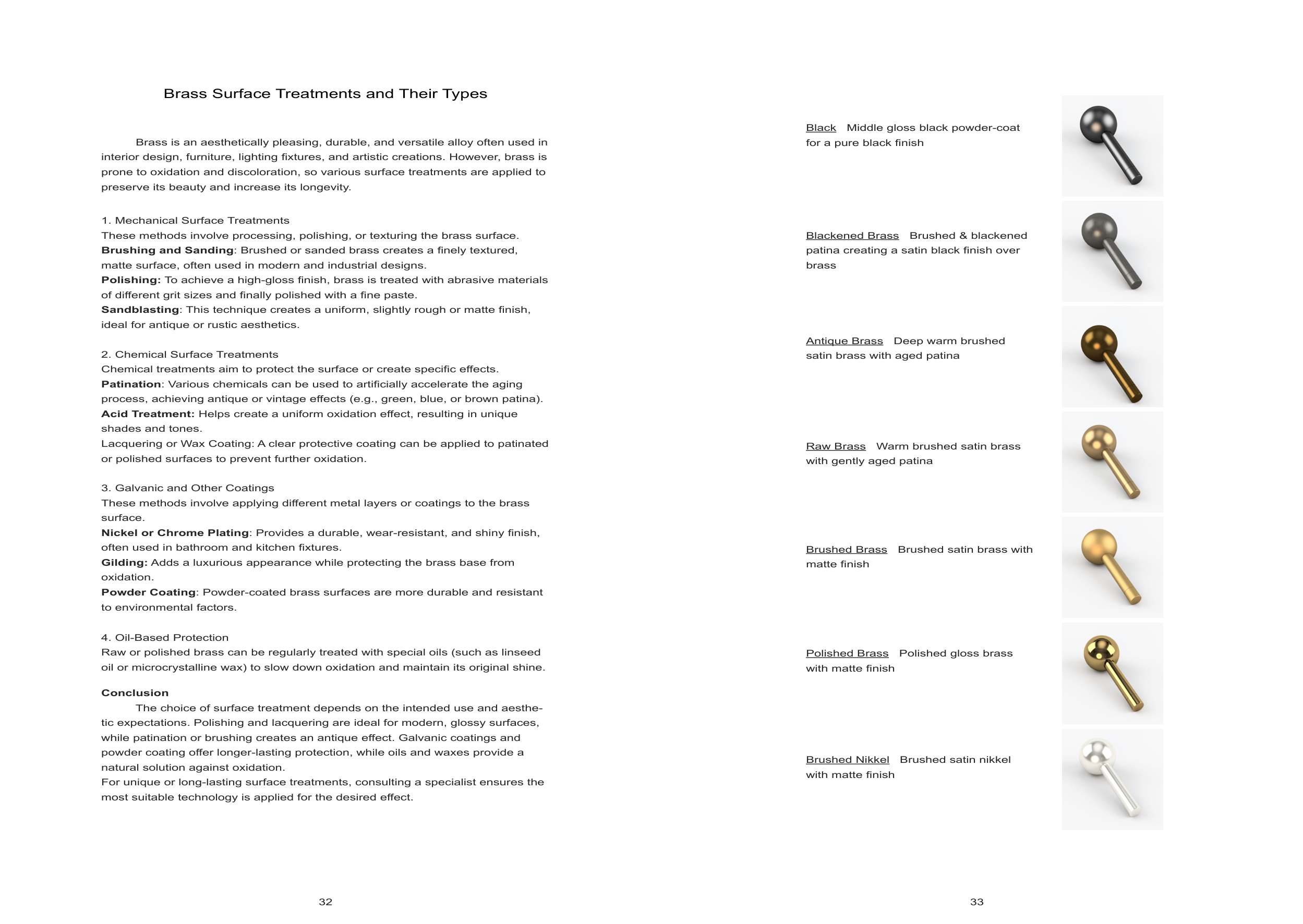

Blackened Brass Brushed & blackened

patina creating a satin black finish over

brass

Raw Brass Warm brushed satin brass

with gently aged patina

Brushed Brass Brushed satin brass with

matte finish

Polished Brass Polished gloss brass

with matte finish

Brushed Nikkel Brushed satin nikkel

with matte finish

Antique Brass Deep warm brushed

satin brass with aged patina

Black Middle gloss black powder-coat

for a pure black finish

32

33