dripping hydrochloric acid onto its surface.

Afterwards the product is being put into

the test cabinet for 1000h at 40°C and a

relative humidity of 82%. After this test;

results are being checked according to

ISO 4628-10.

CLIMATE TESTING

Over time, a luminaire will be influenced

by the environment it is installed in, be it by

alternating temperatures or changing levels

of humidity. By simulating the environ-

mental influences in a climate test chamber

we are able to reproduce the effect on our

luminaires but also check extreme stress

parameters like rapidly changing temper-

atures. It allows us to ensure the correct

material choice for different types of

luminaires and improves the reliability and

quality of our products.

COMPONENT TESTING

All luminaires exist out of multiple compo-

nents, therefor a luminaire is only as qual-

itative as its weakest component. Quality

testing on component level is a constant

and essential topic at Delta Light which

requires a high level of know-how as all

components exist out of different materials,

can be electronic or electric and are being

used in different circumstances. Looking

for the best quality in both components

and manufacturers requires a strict policy

in testing and supplier selection.

ELECTROMAGNETIC

COMPATIBILITY TESTING

EMC testing according to IEC 61547, IEC

55015, IEC 61000-3-2, IEC 61000-3-3

Electrical products can emit electromag-

netic waves. When releasing electrical

equipment for the EU market, it has to

apply to the norms set by EU directives.

These tests are done to make sure that

there will be no mutual interference from

the luminaire towards its environment in

order to not hinder the correct operation

of the equipment.

OPTICAL SIMULATION

Light quality also depends on the way the

light is being controlled by the optics when

it leaves the light source. We pay specific

attention to the final result when choosing

or designing our optics. Using computer

simulations allows to check at an early

stage how the optics need to be shaped

and where it needs to be positioned. By

making computer simulations we can

already make an accurate estimation of how

the luminaire will perform in a final stage.

Apart from simulating the final effect of the

luminaire, these simulations are also being

used to develop the most energy-efficient

lighting solutions possible and can be used

to see what the effect of an accessory will

be when applied onto the luminaire.

PHOTOMETRICS

Apart from the lumen output and the

power it consumes, a luminaire is char-

acterized by its luminous distribution. At

Delta Light® we have the knowledge and

infrastructure in-house to determine those

characteristics of the luminous distribution.

QUALITY CONTROL AND

PRODUCTION

At different stages of the manufacturing –

during the complete process from compo-

nents to finished product - routine testing

on functionality and safety is being done to

assure the highest level of quality. After full

assembly, each luminaire itself is undergoing

a final test and is being marked,

hereafter it is being packed and labeled,

ready for transportation. Some examples

of this functional testing are checking if the

light effect and output is correct, check-

ing if all hinges or other moving parts are

working fine or checking if there are no

irregularities on the electrical wiring.

OPTICAL SPECTOMETRY

Together with the luminous distribution,

also the quality of light is of main impor-

tance: what is the total luminous flux, how

does the spectrum looks like, …? By using

spectroradiometers the quality of light from

the light source and the complete luminaire

can be checked into detail and optimized

to our Delta Light standards. To learn more

about our research and development, visit

deltalight.com

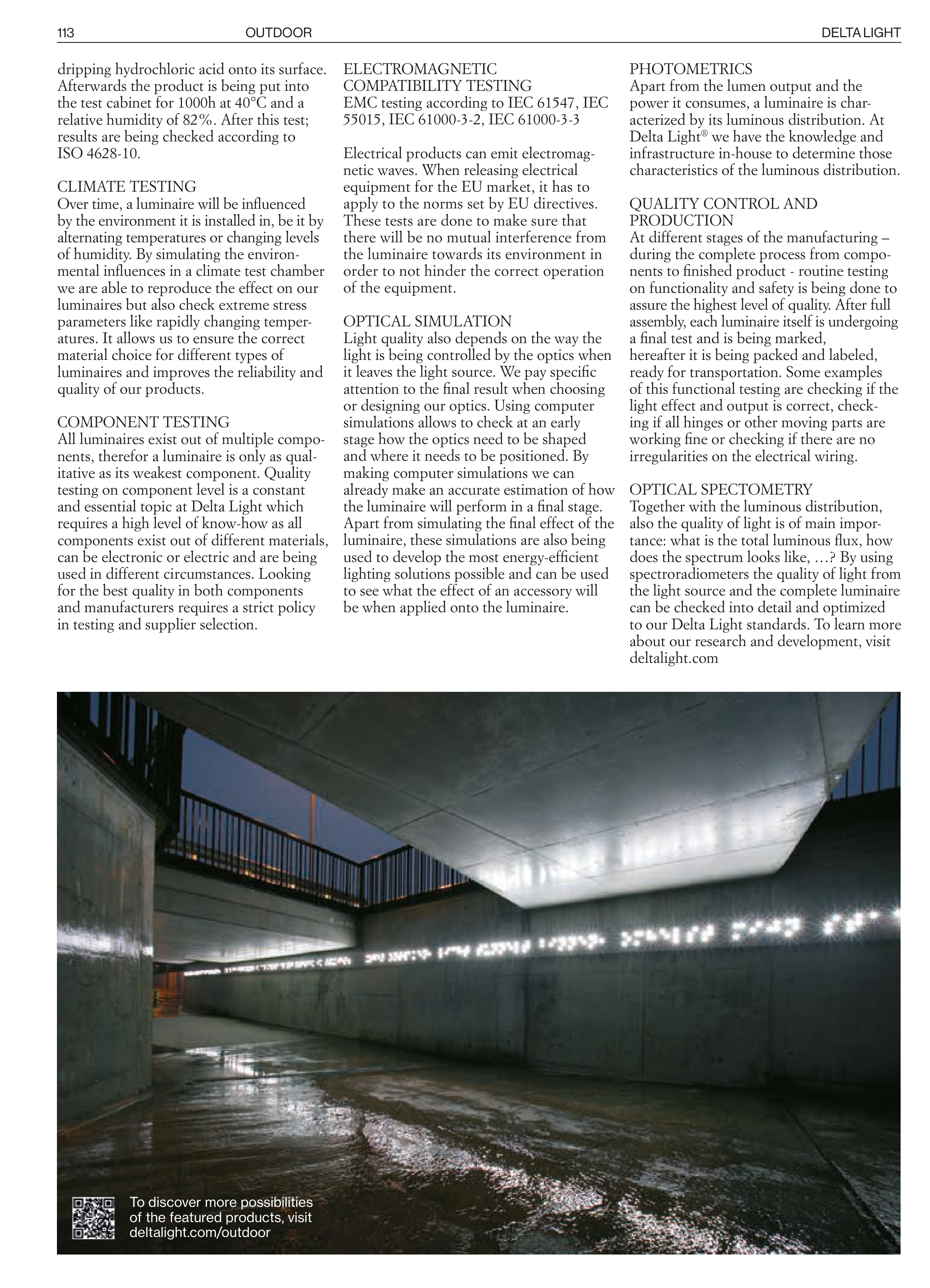

To discover more possibilities

of the featured products, visit

deltalight.com/outdoor

113

OUTDOOR

DELTA LIGHT