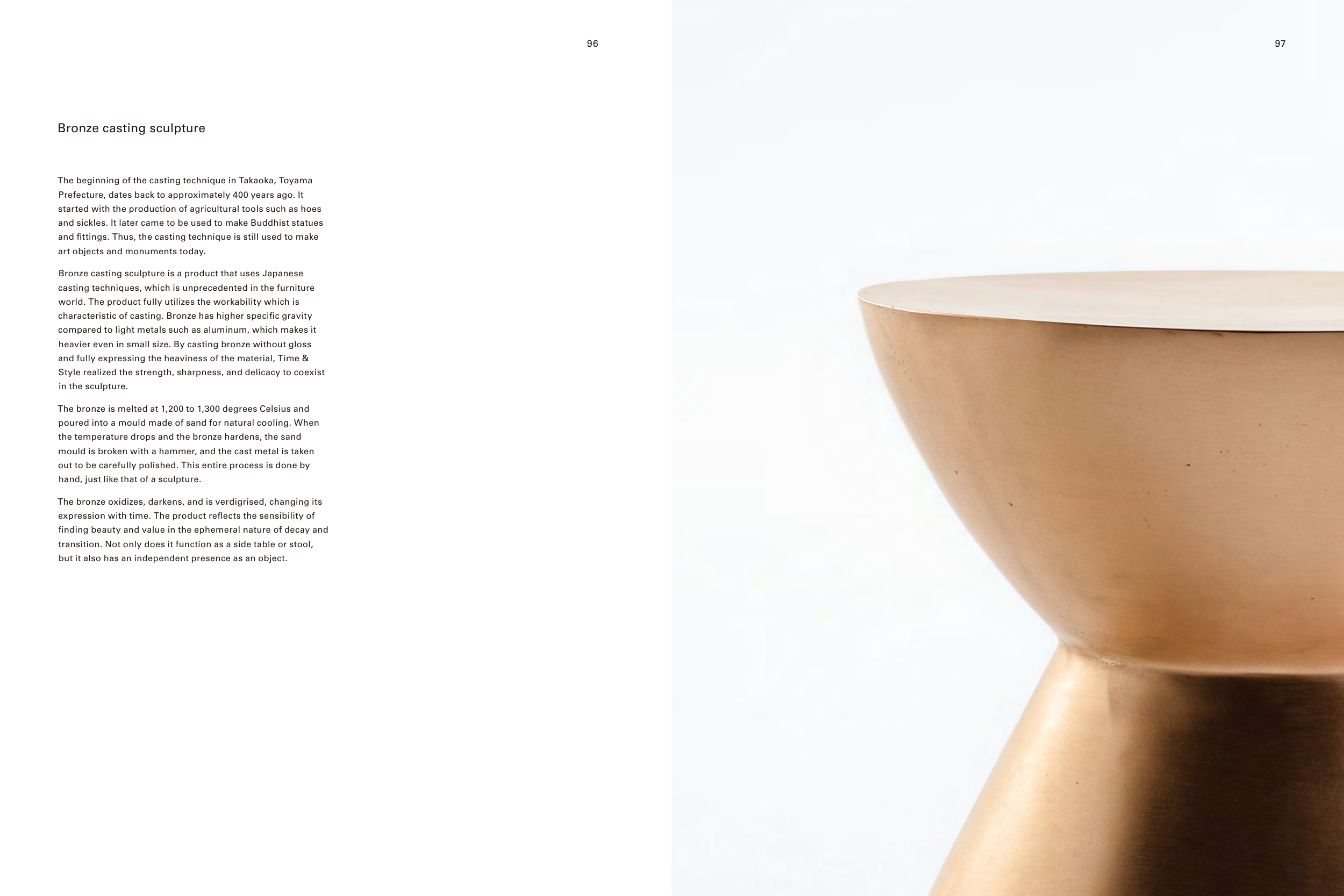

Bronze casting sculpture

The beginning of the casting technique in Takaoka, Toyama

Prefecture, dates back to approximately 400 years ago. It

started with the production of agricultural tools such as hoes

and sickles. It later came to be used to make Buddhist statues

and fittings. Thus, the casting technique is still used to make

art objects and monuments today.

Bronze casting sculpture is a product that uses Japanese

casting techniques, which is unprecedented in the furniture

world. The product fully utilizes the workability which is

characteristic of casting. Bronze has higher specific gravity

compared to light metals such as aluminum, which makes it

heavier even in small size. By casting bronze without gloss

and fully expressing the heaviness of the material, Time &

Style realized the strength, sharpness, and delicacy to coexist

in the sculpture.

The bronze is melted at 1,200 to 1,300 degrees Celsius and

poured into a mould made of sand for natural cooling. When

the temperature drops and the bronze hardens, the sand

mould is broken with a hammer, and the cast metal is taken

out to be carefully polished. This entire process is done by

hand, just like that of a sculpture.

The bronze oxidizes, darkens, and is verdigrised, changing its

expression with time. The product reflects the sensibility of

finding beauty and value in the ephemeral nature of decay and

transition. Not only does it function as a side table or stool,

but it also has an independent presence as an object.

96

97