126

127

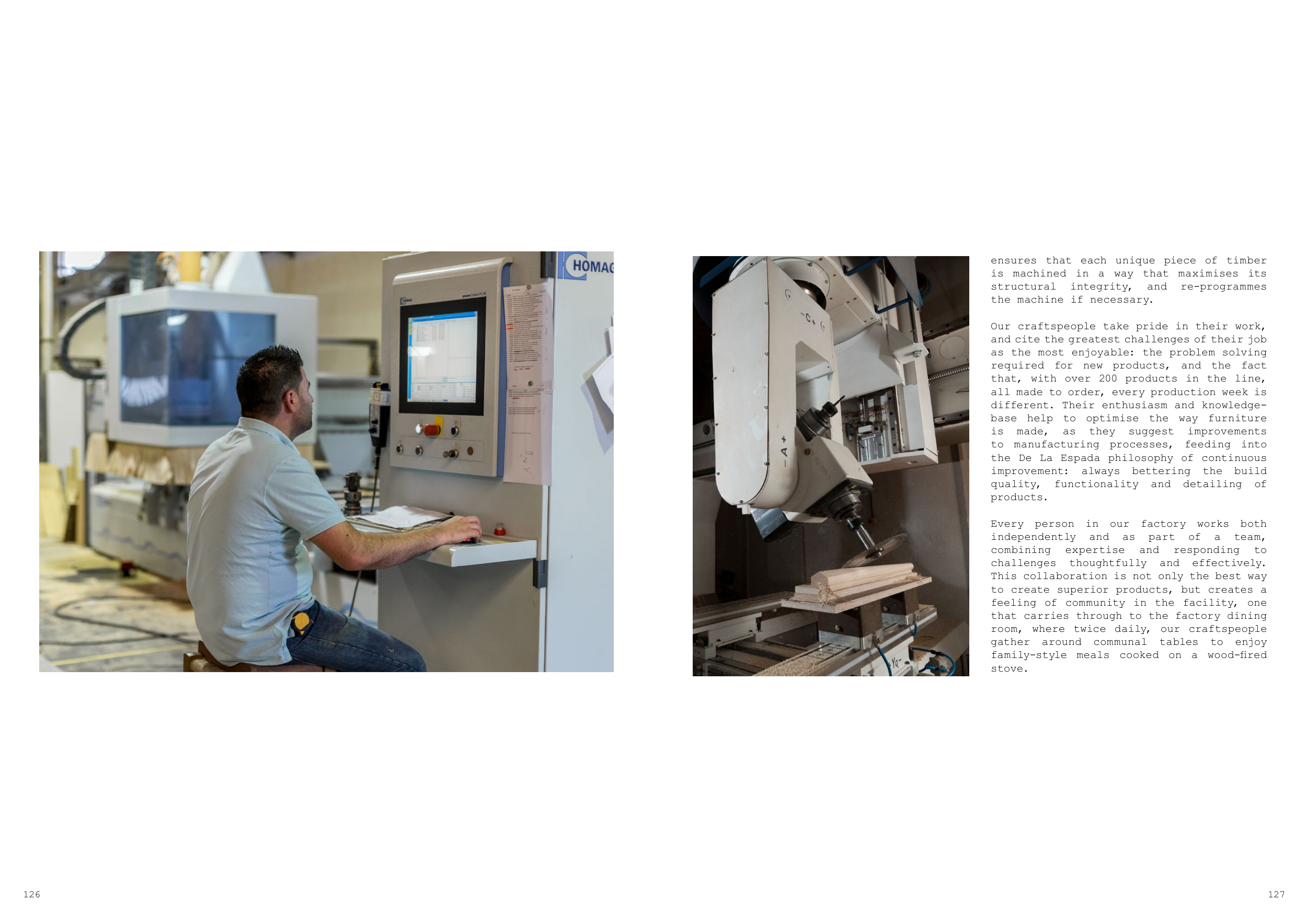

ensures that each unique piece of timber

is machined in a way that maximises its

structural integrity, and re-programmes

the machine if necessary.

Our craftspeople take pride in their work,

and cite the greatest challenges of their job

as the most enjoyable: the problem solving

required for new products, and the fact

that, with over 200 products in the line,

all made to order, every production week is

different. Their enthusiasm and knowledge-

base help to optimise the way furniture

is made, as they suggest improvements

to manufacturing processes, feeding into

the De La Espada philosophy of continuous

improvement: always bettering the build

quality, functionality and detailing of

products.

Every person in our factory works both

independently and as part of a team,

combining expertise and responding to

challenges thoughtfully and effectively.

This collaboration is not only the best way

to create superior products, but creates a

feeling of community in the facility, one

that carries through to the factory dining

room, where twice daily, our craftspeople

gather around communal tables to enjoy

family-style meals cooked on a wood-fired

stove.