124

125

decisions at every stage of manufacture

ensuring superior products in a way that

only thoughtful human intervention can.

A famously challenging material with a

wide range of natural variations and life-

long movement, solid wood is unforgiving,

yet its rewards are many. What can compare

to the silky touch, the entirely unique

surface characteristics that nod to the

life of the tree, the subtle shimmer of

an oil finish, the nutty fragrance released

when sanding, or the relationship that

forms between object and memory as history

begins to leave its mark? The expressive

physicality, workability, and enduring

strength of wood have made it a favourite

for furniture making throughout time, from

the bentwood chairs of Michael Thonet,

to the architectural furniture of Frank

Lloyd Wright, to the soulful creations

of George Nakashima that combine refined

elements with wild sections of trunk

replete with knots and cracks secured with

butterfly joints. Each author works with

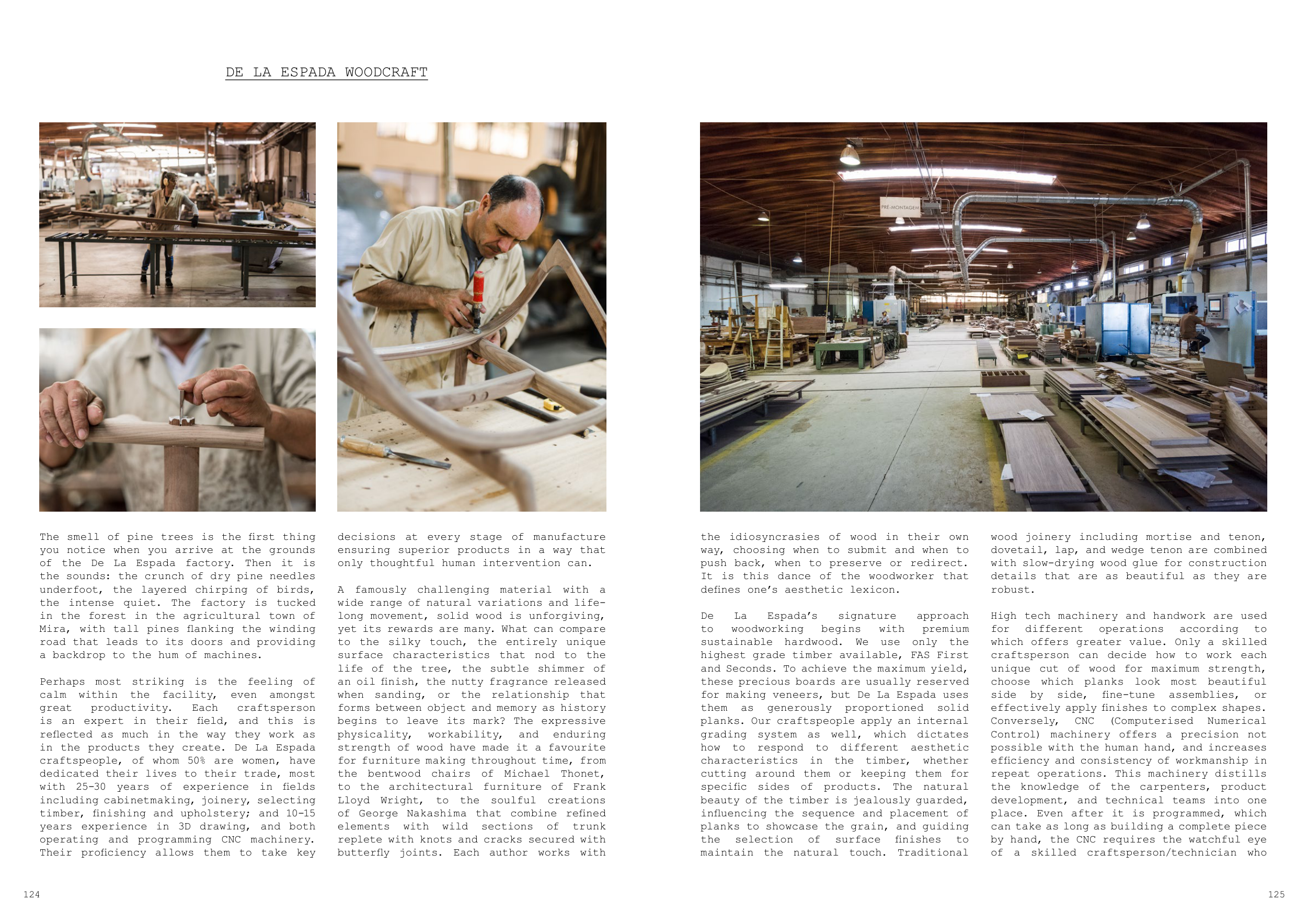

The smell of pine trees is the first thing

you notice when you arrive at the grounds

of the De La Espada factory. Then it is

the sounds: the crunch of dry pine needles

underfoot, the layered chirping of birds,

the intense quiet. The factory is tucked

in the forest in the agricultural town of

Mira, with tall pines flanking the winding

road that leads to its doors and providing

a backdrop to the hum of machines.

Perhaps most striking is the feeling of

calm within the facility, even amongst

great

productivity.

Each

craftsperson

is an expert in their field, and this is

reflected as much in the way they work as

in the products they create. De La Espada

craftspeople, of whom 50% are women, have

dedicated their lives to their trade, most

with 25-30 years of experience in fields

including cabinetmaking, joinery, selecting

timber, finishing and upholstery; and 10-15

years experience in 3D drawing, and both

operating and programming CNC machinery.

Their proficiency allows them to take key

DE LA ESPADA WOODCRAFT

the idiosyncrasies of wood in their own

way, choosing when to submit and when to

push back, when to preserve or redirect.

It is this dance of the woodworker that

defines one’s aesthetic lexicon.

De

La

Espada’s

signature

approach

to

woodworking

begins

with

premium

sustainable hardwood. We use only the

highest grade timber available, FAS First

and Seconds. To achieve the maximum yield,

these precious boards are usually reserved

for making veneers, but De La Espada uses

them as generously proportioned solid

planks. Our craftspeople apply an internal

grading system as well, which dictates

how to respond to different aesthetic

characteristics in the timber, whether

cutting around them or keeping them for

specific sides of products. The natural

beauty of the timber is jealously guarded,

influencing the sequence and placement of

planks to showcase the grain, and guiding

the selection of surface finishes to

maintain the natural touch. Traditional

wood joinery including mortise and tenon,

dovetail, lap, and wedge tenon are combined

with slow-drying wood glue for construction

details that are as beautiful as they are

robust.

High tech machinery and handwork are used

for

different

operations

according

to

which offers greater value. Only a skilled

craftsperson can decide how to work each

unique cut of wood for maximum strength,

choose which planks look most beautiful

side by side, fine-tune assemblies, or

effectively apply finishes to complex shapes.

Conversely, CNC (Computerised Numerical

Control) machinery offers a precision not

possible with the human hand, and increases

efficiency and consistency of workmanship in

repeat operations. This machinery distills

the knowledge of the carpenters, product

development, and technical teams into one

place. Even after it is programmed, which

can take as long as building a complete piece

by hand, the CNC requires the watchful eye

of a skilled craftsperson/technician who