C 05 47

A new Third Industrial Revolution manufacturing model has seized

the public stage and is growing exponentially. Hundreds of companies

are now producing physical products the way software produces infor-

mation in the form of video, audio, and text. It’s called 3D printing.

Printers are already producing products from jewelry and airplane

parts to human prostheses. And cheap printers are being purchased

by hobbyists interested in printing out their own parts and products.

The consumer is beginning to give way to the prosumer as increasing

numbers of people become both the producer and consumer of their

own products. Three-dimensional printing differs from conventional

centralized manufacturing in several important ways.

First, there is little human involvement aside from creating the

software. The software does all the work, which is why it’s more

appropriate to think of the process as “infofacture” rather than

“manufacture.”

Second, the early practitioners of 3D printing have made strides

to ensure that the software used remains open source, allowing pro-

sumers to share new ideas with one another do-it-yourself hobbyist

networks. The open design concept conceives of the production of

goods as a dynamic process in which thousands – even millions – of

players learn from one another by making things together.

Third, the production process is organized completely different

than the traditional manufacturing process. 3D printing is additive

infofacturing, which uses one-tenth of the material of subtractive

manufacturing, giving the 3D printer a substantial leg up in efficiency.

Fourth, 3D printers can print their own spare parts without having

to invest in expensive retooling and the time delays that go with it.

Fifth, the 3D printing movement is deeply committed to sustainable

production and its emphasis is on durability and recyclability and

using nonpolluting materials.

Sixth, 3D printers can set up shop and connect anywhere there is

a Third Industrial Revolution (TIR) infrastructure and enjoy thermo-

dynamic efficiencies far beyond those of centralized factories, with

productivity gains.

Finally, plugging into an IoT infrastructure (internet of things) at

the local level gives the small infofacturers one final, critical advan-

tage over the verticality integrated, centralized of the nineteenth and

twentieth centuries: they can power their vehicles with renewable

energy whose marginal cost is nearly free, significantly reducing their

logistics costs along the supply chain and in the delivery of their

finished products to users.

The ability to produce, market, and distribute physical goods any-

where there is an IoT infrastructure to plug into is going to dramatically

affect the spatial organization of society. Three-dimensional printing

is both local and global; it is also highly mobile, allowing infofacturers

to be anywhere and quickly move to wherever there is an IoT infra-

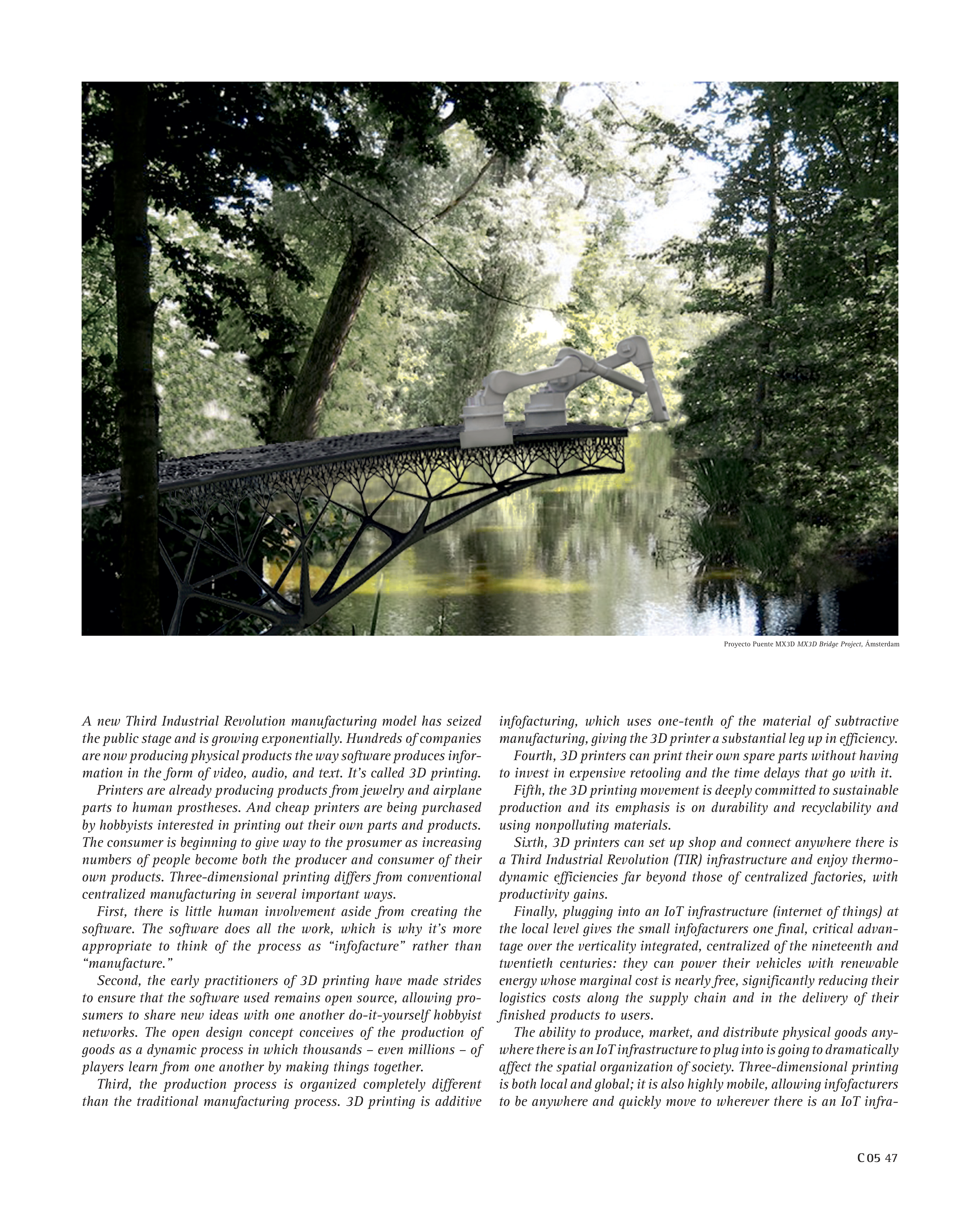

Proyecto Puente MX3D MX3D Bridge Project, Ámsterdam