115

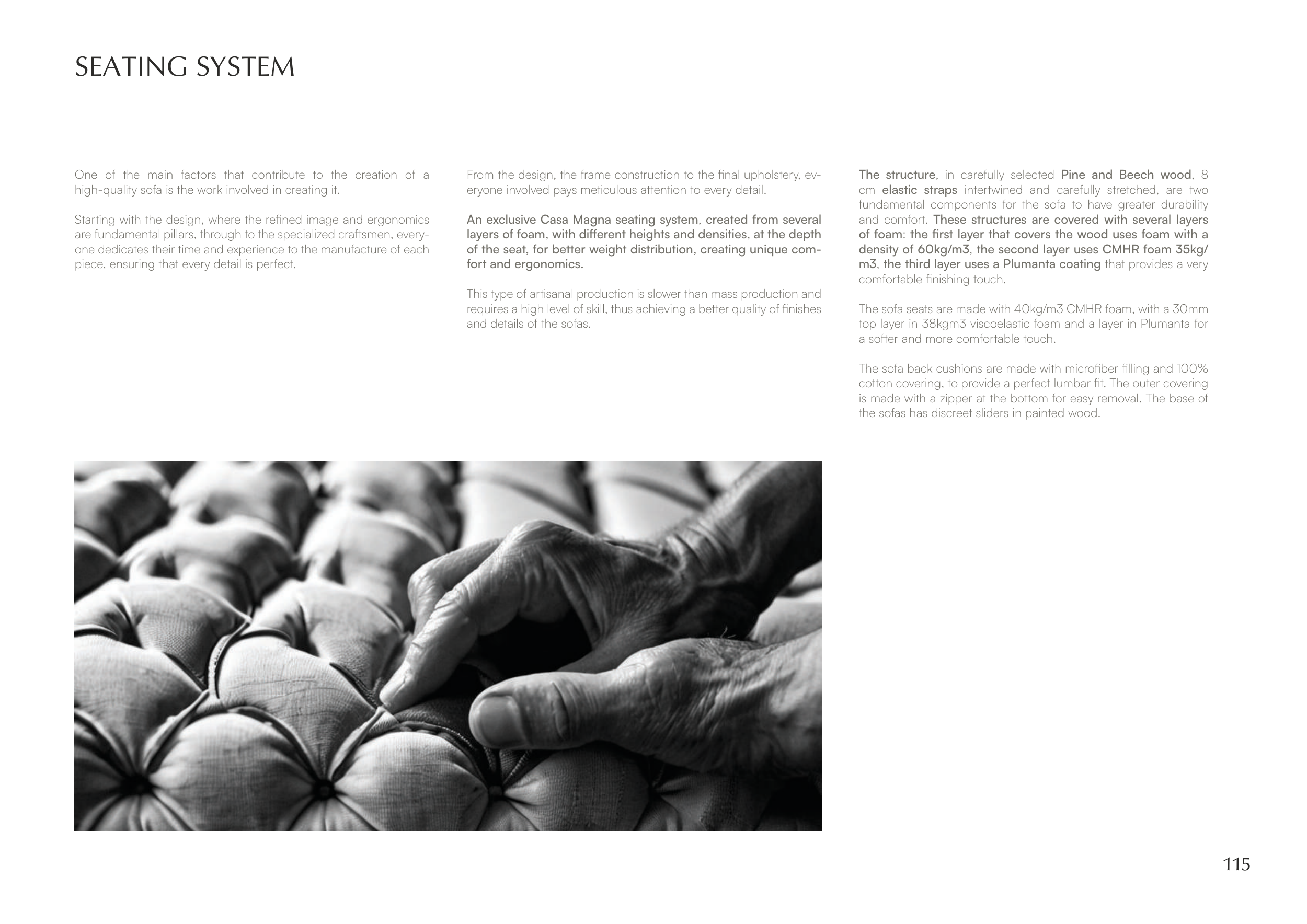

One of the main factors that contribute to the creation of a

high-quality sofa is the work involved in creating it.

Starting with the design, where the refined image and ergonomics

are fundamental pillars, through to the specialized craftsmen, every-

one dedicates their time and experience to the manufacture of each

piece, ensuring that every detail is perfect.

From the design, the frame construction to the final upholstery, ev-

eryone involved pays meticulous attention to every detail.

An exclusive Casa Magna seating system, created from several

layers of foam, with different heights and densities, at the depth

of the seat, for better weight distribution, creating unique com-

fort and ergonomics.

This type of artisanal production is slower than mass production and

requires a high level of skill, thus achieving a better quality of finishes

and details of the sofas.

SEATING SYSTEM

The structure, in carefully selected Pine and Beech wood, 8

cm elastic straps intertwined and carefully stretched, are two

fundamental components for the sofa to have greater durability

and comfort. These structures are covered with several layers

of foam: the first layer that covers the wood uses foam with a

density of 60kg/m3, the second layer uses CMHR foam 35kg/

m3, the third layer uses a Plumanta coating that provides a very

comfortable finishing touch.

The sofa seats are made with 40kg/m3 CMHR foam, with a 30mm

top layer in 38kgm3 viscoelastic foam and a layer in Plumanta for

a softer and more comfortable touch.

The sofa back cushions are made with microfiber filling and 100%

cotton covering, to provide a perfect lumbar fit. The outer covering

is made with a zipper at the bottom for easy removal. The base of

the sofas has discreet sliders in painted wood.