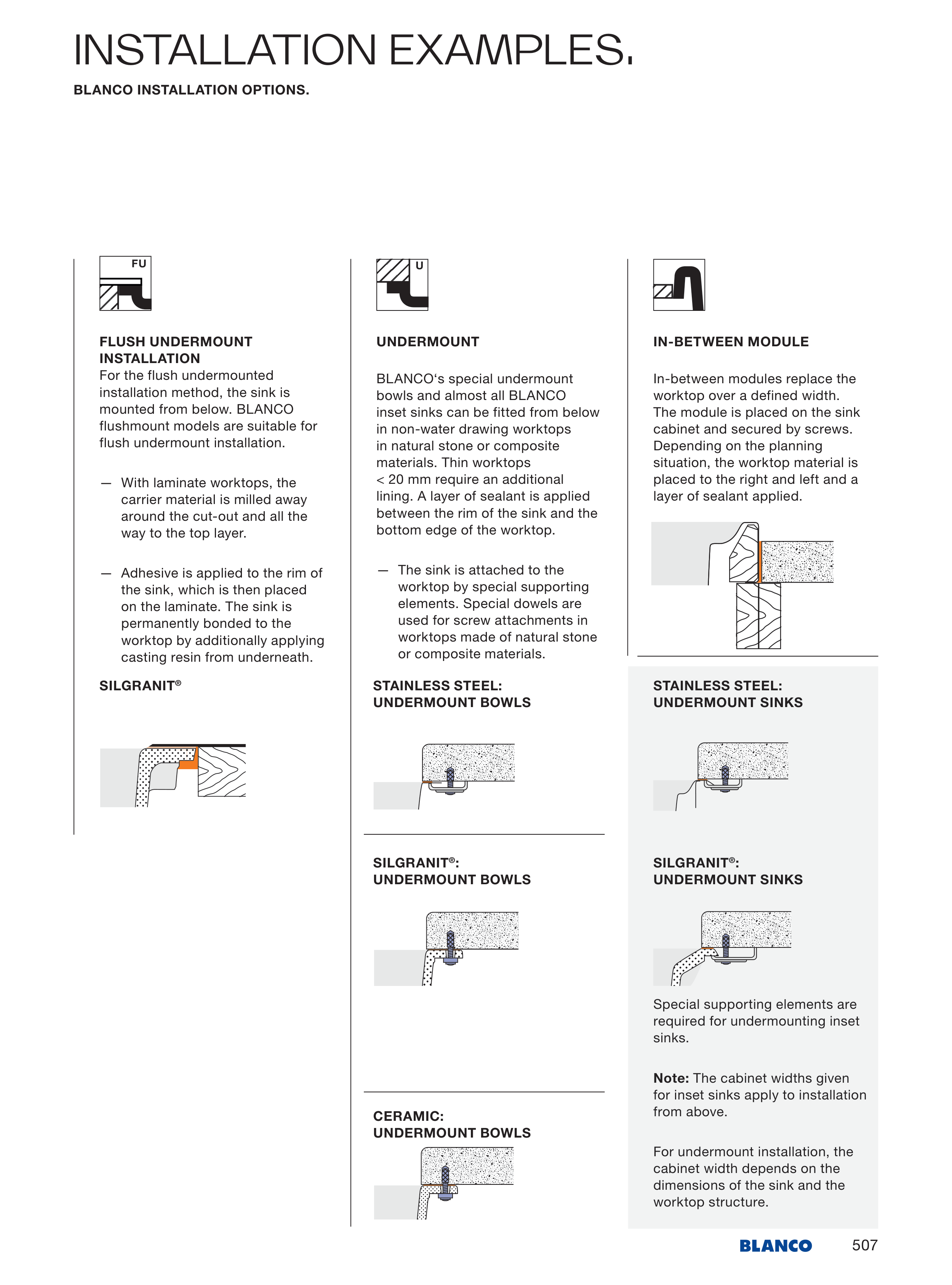

FLUSH UNDERMOUNT

INSTALLATION

For the flush undermounted

installation method, the sink is

mounted from below. BLANCO

flushmount models are suitable for

flush undermount installation.

— With laminate worktops, the

carrier material is milled away

around the cut-out and all the

way to the top layer.

— Adhesive is applied to the rim of

the sink, which is then placed

on the laminate. The sink is

permanently bonded to the

worktop by additionally applying

casting resin from underneath.

UNDERMOUNT

BLANCO‘s special undermount

bowls and almost all BLANCO

inset sinks can be fitted from below

in non-water drawing worktops

in natural stone or composite

materials. Thin worktops

< 20 mm require an additional

lining. A layer of sealant is applied

between the rim of the sink and the

bottom edge of the worktop.

— The sink is attached to the

worktop by special supporting

elements. Special dowels are

used for screw attachments in

worktops made of natural stone

or composite materials.

IN-BETWEEN MODULE

In-between modules replace the

worktop over a defined width.

The module is placed on the sink

cabinet and secured by screws.

Depending on the planning

situation, the worktop material is

placed to the right and left and a

layer of sealant applied.

Special supporting elements are

required for undermounting inset

sinks.

Note: The cabinet widths given

for inset sinks apply to installation

from above.

For undermount installation, the

cabinet width depends on the

dimensions of the sink and the

worktop structure.

CERAMIC:

UNDERMOUNT BOWLS

SILGRANIT®

STAINLESS STEEL:

UNDERMOUNT SINKS

STAINLESS STEEL:

UNDERMOUNT BOWLS

SILGRANIT®:

UNDERMOUNT SINKS

SILGRANIT®:

UNDERMOUNT BOWLS

INSTALLATION EXAMPLES.

BLANCO INSTALLATION OPTIONS.

507