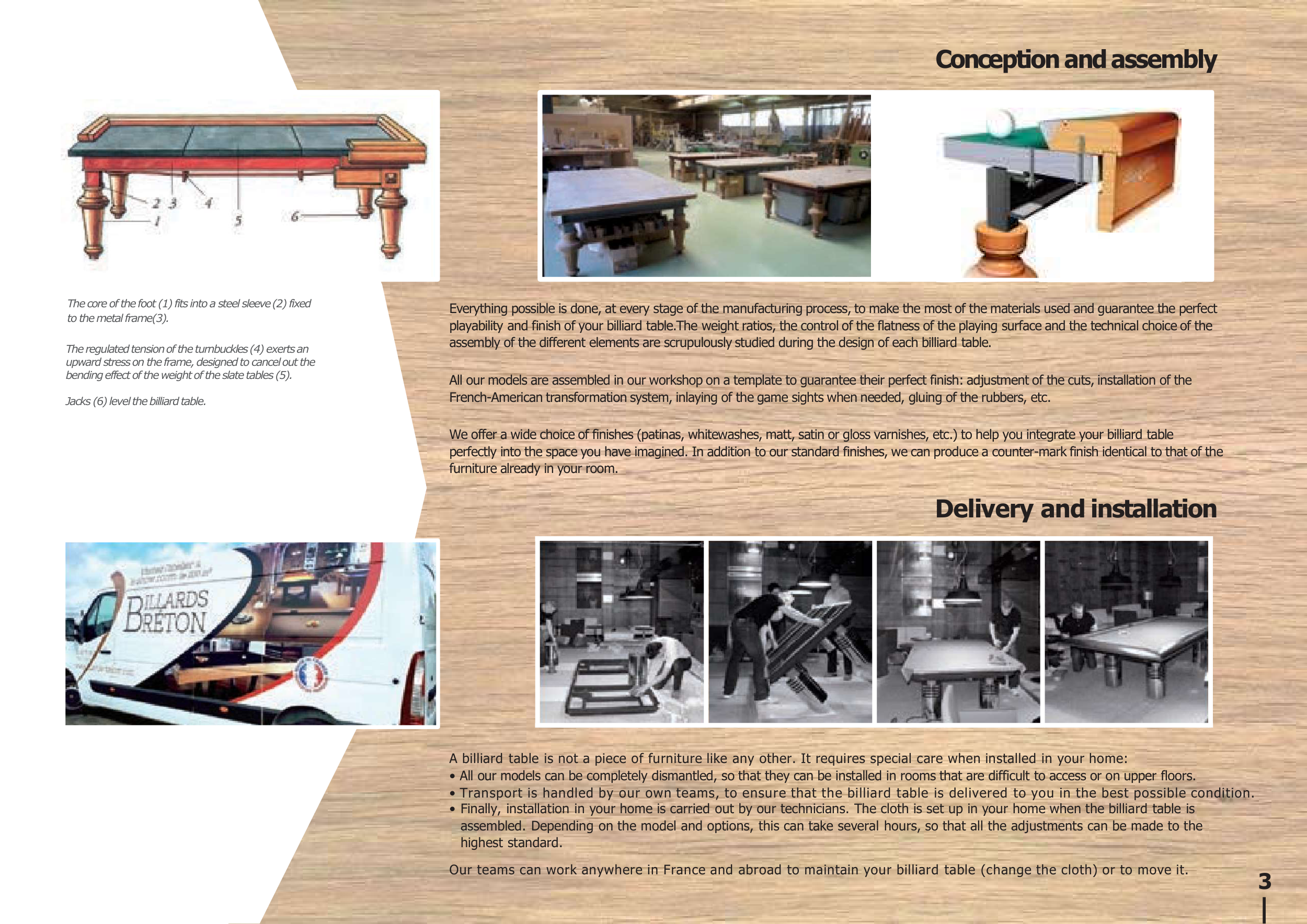

The core of the foot (1) fits into a steel sleeve (2) fixed

to the metal frame(3).

The regulated tension of the turnbuckles (4) exerts an

upward stress on the frame, designed to cancel out the

bending effect of the weight of the slate tables (5).

Jacks (6) level the billiard table.

Everything possible is done, at every stage of the manufacturing process, to make the most of the materials used and guarantee the perfect

playability and finish of your billiard table.The weight ratios, the control of the flatness of the playing surface and the technical choice of the

assembly of the different elements are scrupulously studied during the design of each billiard table.

All our models are assembled in our workshop on a template to guarantee their perfect finish: adjustment of the cuts, installation of the

French-American transformation system, inlaying of the game sights when needed, gluing of the rubbers, etc.

We offer a wide choice of finishes (patinas, whitewashes, matt, satin or gloss varnishes, etc.) to help you integrate your billiard table

perfectly into the space you have imagined. In addition to our standard finishes, we can produce a counter-mark finish identical to that of the

furniture already in your room.

A billiard table is not a piece of furniture like any other. It requires special care when installed in your home:

• All our models can be completely dismantled, so that they can be installed in rooms that are difficult to access or on upper floors.

• Transport is handled by our own teams, to ensure that the billiard table is delivered to you in the best possible condition.

• Finally, installation in your home is carried out by our technicians. The cloth is set up in your home when the billiard table is

assembled. Depending on the model and options, this can take several hours, so that all the adjustments can be made to the

highest standard.

Our teams can work anywhere in France and abroad to maintain your billiard table (change the cloth) or to move it.

Delivery and installation

Conception andassembly

3