Know How

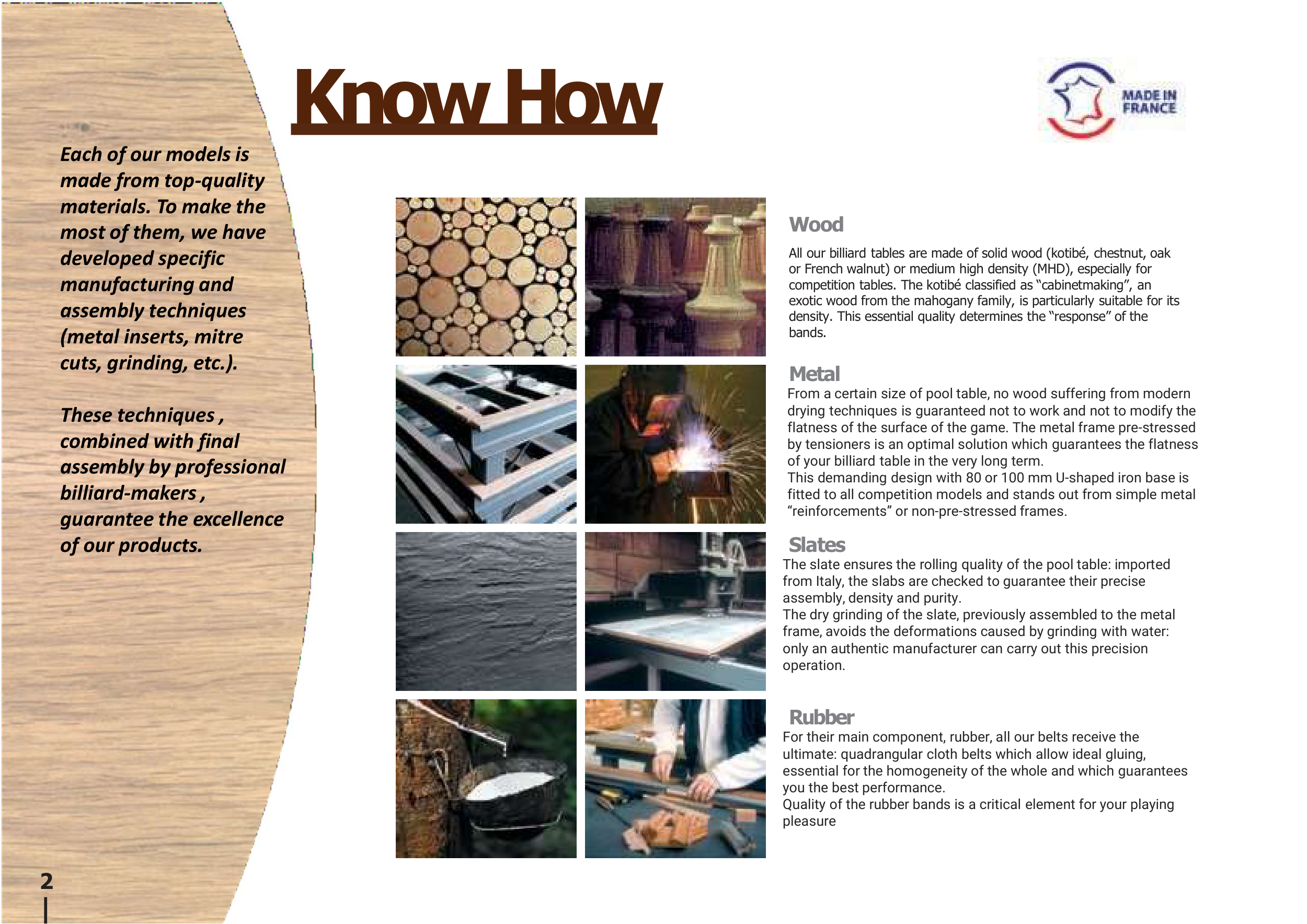

Slates

The slate ensures the rolling quality of the pool table: imported

from Italy, the slabs are checked to guarantee their precise

assembly, density and purity.

The dry grinding of the slate, previously assembled to the metal

frame, avoids the deformations caused by grinding with water:

only an authentic manufacturer can carry out this precision

operation.

Rubber

For their main component, rubber, all our belts receive the

ultimate: quadrangular cloth belts which allow ideal gluing,

essential for the homogeneity of the whole and which guarantees

you the best performance.

Quality of the rubber bands is a critical element for your playing

pleasure

Metal

From a certain size of pool table, no wood suffering from modern

drying techniques is guaranteed not to work and not to modify the

flatness of the surface of the game. The metal frame pre-stressed

by tensioners is an optimal solution which guarantees the flatness

of your billiard table in the very long term.

This demanding design with 80 or 100 mm U-shaped iron base is

fitted to all competition models and stands out from simple metal

“reinforcements” or non-pre-stressed frames.

Each of our models is

made from top-quality

materials. To make the

most of them, we have

developed specific

manufacturing and

assembly techniques

(metal inserts, mitre

cuts, grinding, etc.).

These techniques ,

combined with final

assembly by professional

billiard-makers ,

guarantee the excellence

of our products.

Wood

All our billiard tables are made of solid wood (kotibé, chestnut, oak

or French walnut) or medium high density (MHD), especially for

competition tables. The kotibé classified as “cabinetmaking”, an

exotic wood from the mahogany family, is particularly suitable for its

density. This essential quality determines the “response” of the

bands.

2