H

h

d

Ø

D

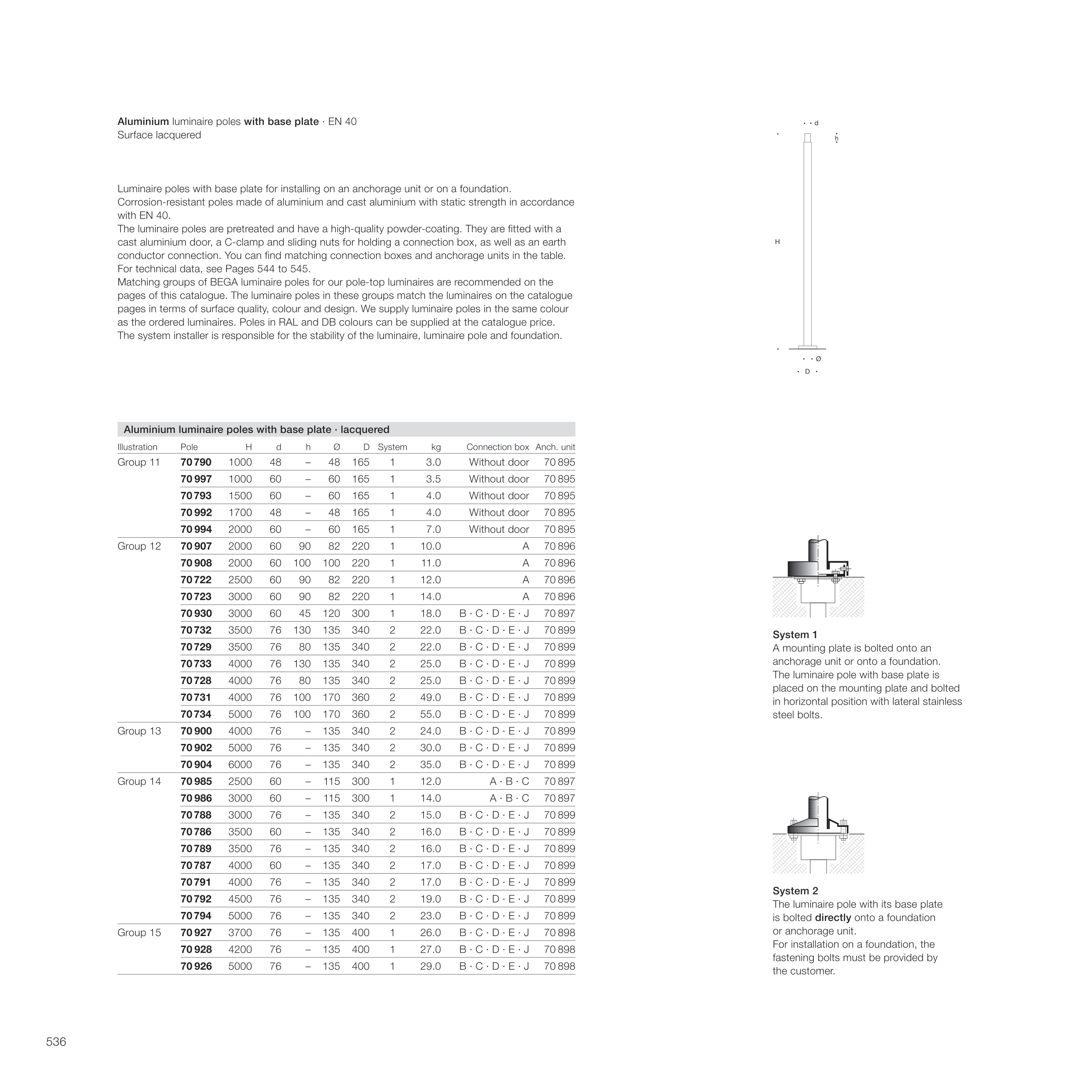

Aluminium luminaire poles with base plate · EN 40

Surface lacquered

System 2

The luminaire pole with its base plate

is bolted directly onto a foundation

or anchorage unit.

For installation on a foundation, the

fastening bolts must be provided by

the customer.

System 1

A mounting plate is bolted onto an

anchorage unit or onto a foundation.

The luminaire pole with base plate is

placed on the mounting plate and bolted

in horizontal position with lateral stainless

steel bolts.

Luminaire poles with base plate for installing on an anchorage unit or on a foundation.

Corrosion-resistant poles made of aluminium and cast aluminium with static strength in accordance

with EN 40.

The luminaire poles are pretreated and have a high-quality powder-coating. They are fitted with a

cast aluminium door, a C-clamp and sliding nuts for holding a connection box, as well as an earth

conductor connection. You can find matching connection boxes and anchorage units in the table.

For technical data, see Pages 544 to 545.

Matching groups of BEGA luminaire poles for our pole-top luminaires are recommended on the

pages of this catalogue. The luminaire poles in these groups match the luminaires on the catalogue

pages in terms of surface quality, colour and design. We supply luminaire poles in the same colour

as the ordered luminaires. Poles in RAL and DB colours can be supplied at the catalogue price.

The system installer is responsible for the stability of the luminaire, luminaire pole and foundation.

Aluminium luminaire poles with base plate · lacquered

Illustration

Pole

H

d

h

Ø

D

System

kg

Connection box Anch. unit

Group 11

70 790

1000

48

–

48

165

1

3.0

Without door

70 895

70 997

1000

60

–

60

165

1

3.5

Without door

70 895

70 793

1500

60

–

60

165

1

4.0

Without door

70 895

70 992

1700

48

–

48

165

1

4.0

Without door

70 895

70 994

2000

60

–

60

165

1

7.0

Without door

70 895

Group 12

70 907

2000

60

90

82

220

1

10.0

A

70 896

70 908

2000

60

100

100

220

1

11.0

A

70 896

70 722

2500

60

90

82

220

1

12.0

A

70 896

70 723

3000

60

90

82

220

1

14.0

A

70 896

70 930

3000

60

45

120

300

1

18.0

B · C · D · E · J

70 897

70 732

3500

76

130

135

340

2

22.0

B · C · D · E · J

70 899

70 729

3500

76

80

135

340

2

22.0

B · C · D · E · J

70 899

70 733

4000

76

130

135

340

2

25.0

B · C · D · E · J

70 899

70 728

4000

76

80

135

340

2

25.0

B · C · D · E · J

70 899

70 731

4000

76

100

170

360

2

49.0

B · C · D · E · J

70 899

70 734

5000

76

100

170

360

2

55.0

B · C · D · E · J

70 899

Group 13

70 900

4000

76

–

135

340

2

24.0

B · C · D · E · J

70 899

70 902

5000

76

–

135

340

2

30.0

B · C · D · E · J

70 899

70 904

6000

76

–

135

340

2

35.0

B · C · D · E · J

70 899

Group 14

70 985

2500

60

–

115

300

1

12.0

A · B · C

70 897

70 986

3000

60

–

115

300

1

14.0

A · B · C

70 897

70 788

3000

76

–

135

340

2

15.0

B · C · D · E · J

70 899

70 786

3500

60

–

135

340

2

16.0

B · C · D · E · J

70 899

70 789

3500

76

–

135

340

2

16.0

B · C · D · E · J

70 899

70 787

4000

60

–

135

340

2

17.0

B · C · D · E · J

70 899

70 791

4000

76

–

135

340

2

17.0

B · C · D · E · J

70 899

70 792

4500

76

–

135

340

2

19.0

B · C · D · E · J

70 899

70 794

5000

76

–

135

340

2

23.0

B · C · D · E · J

70 899

Group 15

70 927

3700

76

–

135

400

1

26.0

B · C · D · E · J

70 898

70 928

4200

76

–

135

400

1

27.0

B · C · D · E · J

70 898

70 926

5000

76

–

135

400

1

29.0

B · C · D · E · J

70 898

536

Kat33_BG45_46_529-552_GB_FR.indd 536

28.04.17 08:42