Gople

BIG - Bjarke Ingels Group

2018

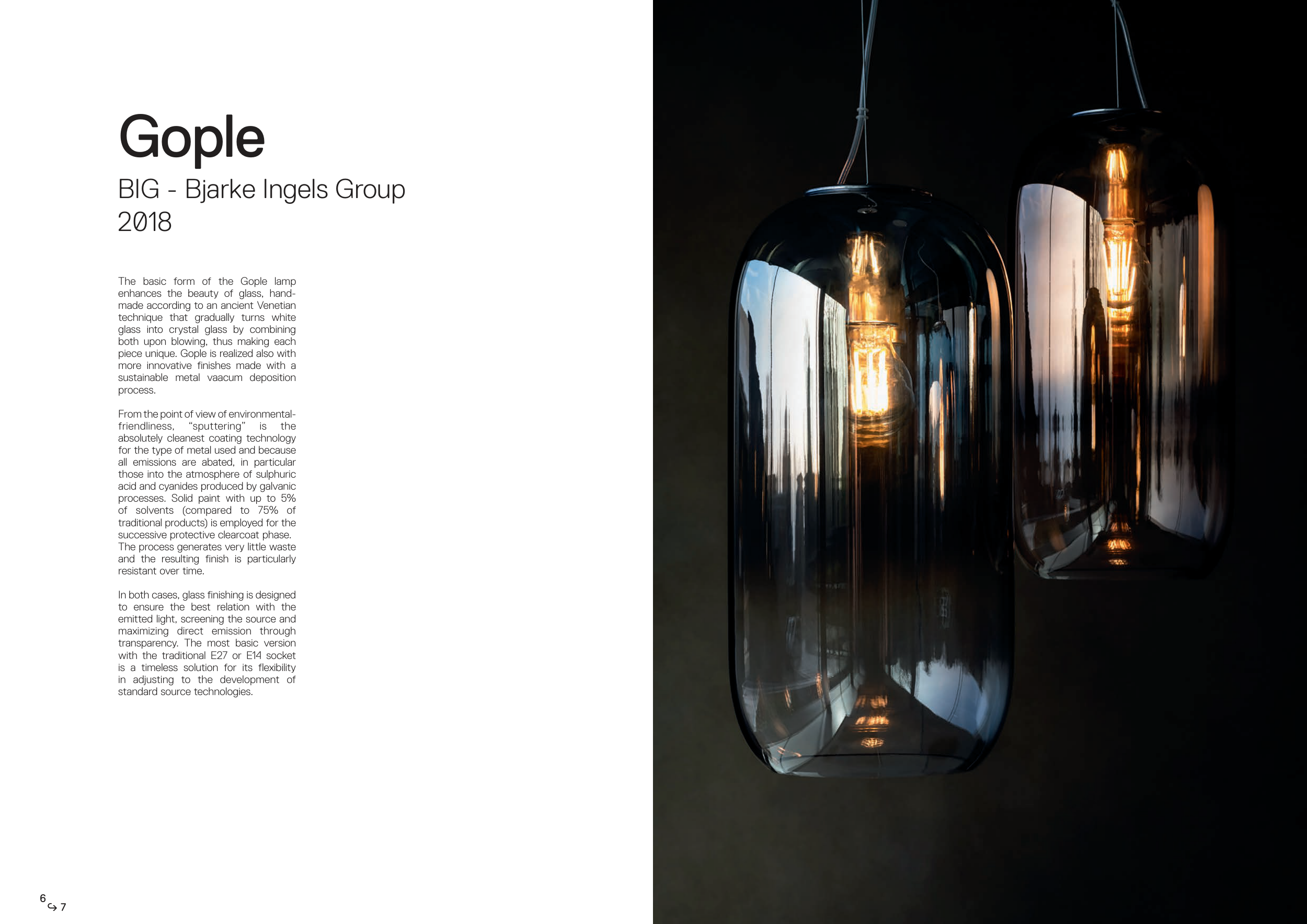

The basic form of the Gople lamp

enhances the beauty of glass, hand-

made according to an ancient Venetian

technique that gradually turns white

glass into crystal glass by combining

both upon blowing, thus making each

piece unique. Gople is realized also with

more innovative finishes made with a

sustainable metal vaacum deposition

process.

From the point of view of environmental-

friendliness,

“sputtering”

is

the

absolutely cleanest coating technology

for the type of metal used and because

all emissions are abated, in particular

those into the atmosphere of sulphuric

acid and cyanides produced by galvanic

processes. Solid paint with up to 5%

of solvents (compared to 75% of

traditional products) is employed for the

successive protective clearcoat phase.

The process generates very little waste

and the resulting finish is particularly

resistant over time.

In both cases, glass finishing is designed

to ensure the best relation with the

emitted light, screening the source and

maximizing direct emission through

transparency. The most basic version

with the traditional E27 or E14 socket

is a timeless solution for its flexibility

in adjusting to the development of

standard source technologies.

6

7