EMISSIONE DIRETTA

EMISSIONE INDIRETTA

DOPPIA EMISSIONE

360

540

720

900

90

100

110

120

760

570

380

950

1140

1

2

3

4

5

H

m

Ø

m

EMax

lux

EM

lux

0,75

1,50

2,26

3,01

3,76

2671

668

297

167

107

1110

277

123

69

44

-90°

90°

400

800

1200

Ø139

Ø110

75

Ø139

85

Max

2000

85

200

87

200

135

200

85

Ø139

43

200

135

Ø139

Ø139

Ø139

Ø139

Ø139

151

85

Ø115

80

151

43

151

151

43

151

43

Key

Classifications

Class I

Device in which electrical safety is provided

by an additional protective conductor (earth)

connected to the metal frame of the lamp.

Class II

Device in which protection against electric shocks

is not provided solely by the basic insulation,

but which has additional safety measures such

as double or reinforced insulation.

These measures do not involve earthing devices

and do not depend on the installation conditions.

Class III

Device in which protection against electric shocks

is based on a safety extra-low voltage power

source and in which no voltages greater than

this can be generated.

A class III device does not need earth protection.

Approvals

ENEC certification of European conformity.

Feeding tension

LV

Low Voltage

Components (electrified plates, optional extensions,

cables and feeding kits) with 3-wire cables (+, -,

signal) and 48VDC feeding tension. Feeding unit

and control interfaces are needed in addition.

Generally used for RGB LEDs, with the exception

of Stand Alone versions.

MV

Medium Voltage

Components (electrified plates, optional extensions,

cables and feeding kits) with 7-wire cables

(Neutral, Direct Line, Indirect Line, Auxiliary Line, Earth,

DALI 1 and DALI 2) and 230 VAC feeding tension.

If dimming is required, an external DALI circuit

complete with DALI power supply, group controller

and scene controller is needed. Used for feeding

and dimming fluorescent lamps, white LEDs,

spot groups and RGB Stand Alone LED versions.

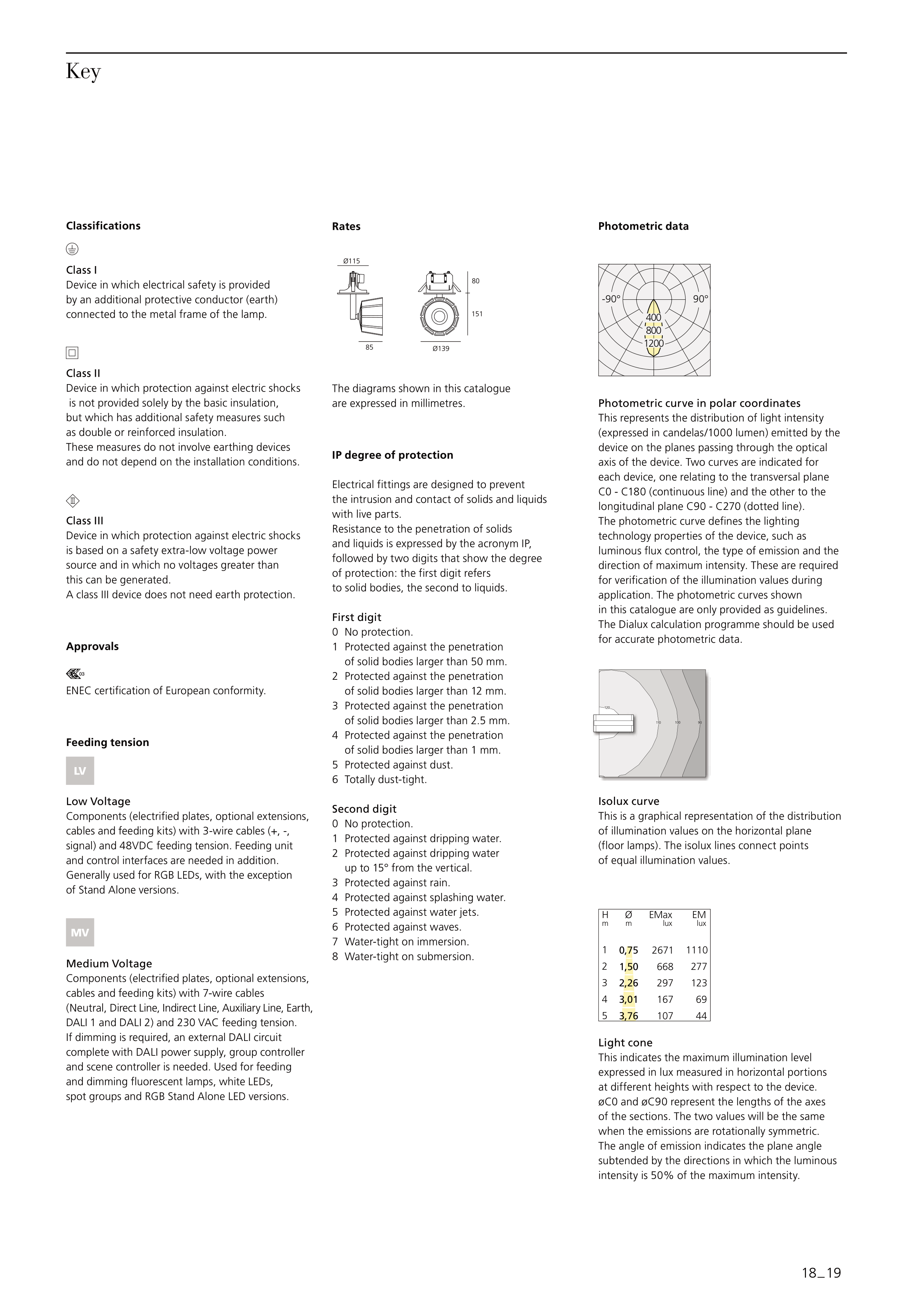

Rates

The diagrams shown in this catalogue

are expressed in millimetres.

IP degree of protection

Electrical fittings are designed to prevent

the intrusion and contact of solids and liquids

with live parts.

Resistance to the penetration of solids

and liquids is expressed by the acronym IP,

followed by two digits that show the degree

of protection: the first digit refers

to solid bodies, the second to liquids.

First digit

0 No protection.

1 Protected against the penetration

of solid bodies larger than 50 mm.

2 Protected against the penetration

of solid bodies larger than 12 mm.

3 Protected against the penetration

of solid bodies larger than 2.5 mm.

4 Protected against the penetration

of solid bodies larger than 1 mm.

5 Protected against dust.

6 Totally dust-tight.

Second digit

0 No protection.

1 Protected against dripping water.

2 Protected against dripping water

up to 15° from the vertical.

3 Protected against rain.

4 Protected against splashing water.

5 Protected against water jets.

6 Protected against waves.

7 Water-tight on immersion.

8 Water-tight on submersion.

Photometric data

Photometric curve in polar coordinates

This represents the distribution of light intensity

(expressed in candelas/1000 lumen) emitted by the

device on the planes passing through the optical

axis of the device. Two curves are indicated for

each device, one relating to the transversal plane

C0 - C180 (continuous line) and the other to the

longitudinal plane C90 - C270 (dotted line).

The photometric curve defines the lighting

technology properties of the device, such as

luminous flux control, the type of emission and the

direction of maximum intensity. These are required

for verification of the illumination values during

application. The photometric curves shown

in this catalogue are only provided as guidelines.

The Dialux calculation programme should be used

for accurate photometric data.

Isolux curve

This is a graphical representation of the distribution

of illumination values on the horizontal plane

(floor lamps). The isolux lines connect points

of equal illumination values.

Light cone

This indicates the maximum illumination level

expressed in lux measured in horizontal portions

at different heights with respect to the device.

øC0 and øC90 represent the lengths of the axes

of the sections. The two values will be the same

when the emissions are rotationally symmetric.

The angle of emission indicates the plane angle

subtended by the directions in which the luminous

intensity is 50% of the maximum intensity.

18 _ 19